Control Technology

Convenient, safe and efficient control

Information & documents

AERZEN control technology

AERZEN is an internationally leading manufacturer of high-performance air compressors and application specialist, in particular in the field of wastewater treatment in wastewater treatment plants. AERZEN doesn't just build machines which compress gaseous media. It has also developed opportunities to implement and control these machines in a highly efficient manner.

In the field of wastewater recycling in wastewater treatment plants, the positive displacement blowers, rotary lobe compressors, screw compressors and turbo blowers are used for the oxygen supply in aeration tanks. Most of the energy requirements of a plant are utilised for the production of compressed air that is required for this. It is therefore very important that the machines are efficiently controlled and only generate as much oxygen as necessary at any one time. If the assemblies are over-utilised when minimal oxygen is required, this will have a negative impact on the efficiency of the overall plant. However, the compressed air requirement in wastewater treatment plants varies greatly. Consumption during the day is high, but less so at night. More water is required in summer than in winter. Water consumption also fluctuates during the day and therefore also the requirement for oxygen in the wastewater treatment plant.

In order to generate a volume flow which is adapted to each actual requirement, AERZEN has developed various innovative and highly-efficient blower controls which automatically regulate the application of various blower or compressor combinations according to requirements. The machines can be connected individually, in pairs or even in threes. This enables the machines to be controlled as efficiently as possible and very closely to the load curve, and prevents plants from supplying oxygen over and above the current requirement.

These innovative, connected solutions and automated processes allow AERZEN to set milestones on the road to Industry 4.0 and to promote trend-setting, resource-saving wastewater management as defined by Water 4.0.

Generally, there are two different types of control: the decentralised control which has a fixed link to a machine and the central control, which coordinates several machines at a higher level outside the individual assemblies – furthermore, a distinction must be made between single-user and global controls. A single-user system, as the name suggests, controls just one “workstation” or a machine in the plant whereas a global control system controls several machines. The following explains and highlights these terms with the help of the compressed air controls AERtronic and AERsmart:

AERtronic

The AERtronic is a traditional local assembly control: AERtronic is being used all over the world to control Delta Blower, Delta Hybrid and Delta Screw machine types from AERZEN. As an individual blower control, it is generally built into the acoustic hood of a machine. However, it can also be installed separately onto a rack.

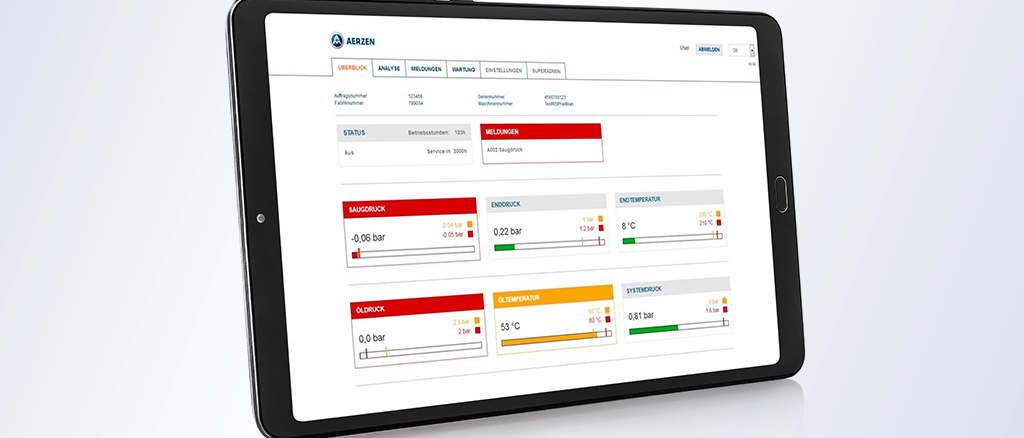

The compressor control opens up a broad spectrum of options and uses for the plant operator: The clear and intuitive 4.3" TFT display (thin film transistor display) with touchscreen allows technicians to control the machine locally, read process data such as operating hours, service hours or operating events and monitor process values on site. After commissioning and entry of the operating parameters (including warning and overload settings), the AERtronic independently takes over control of the machine. For example, based on the key figures, it controls the use of the machine at optimal working pressure. Using an additional module called “WebView”, decentralised monitoring via intranet in the factory is also possible and, using the relevant VPN client, even external control via smartphone, other mobile device or PC is possible from any location in the world. Current operating data, the transfer of error messages, operating hours, alarm messages, vibrational monitoring, service planning and the display and evaluation of process data over predefined time periods can thus be called up, regardless of the location of the compressor.

This kind of monitoring has huge advantages. It primarily gives the opportunity to react promptly to deviations, error or alarm messages. Servicing can be planned more effectively, vibrational monitoring allows better detection of regular wear and tear up to and including carrying out genuine condition monitoring. Compressor control is linked to all current interfaces: In addition to the standard MODBUS RTU, PROFIBUS DP, MODBUS Gateway between RTU and MODBUS TCT (Ethernet) and PROFINET© can all be used. Furthermore, there is an option to extract signals such as incoming and outgoing pressure, oil pressure or temperatures and provide them in the form of a 4-20 mA signal. As a decentralised control, the AERtronic can connect and synchronously control up to five AERZEN machines with the same priority and design via the MODBUS RTU. This base load/toggle switching is already installed in every AERtronic.

The AERtronic has also achieved a new dimension of machine transparency, since it logs and saves its process data on compressor or blower operation together with the corresponding date – which in turn enables the targeted analysis of operating processes at a later date. Based on the data, maintenance and service times can be systematically planned and corrective measures can be introduced in a more targeted manner. This increases the operating times of the machine.

The result is more efficient compressed air control which, depending on requirements, switches on or off machines working in a linked system. This avoids idle times and minimises load run or idle switching cycles.

AERsmart

Unlike AERtronic, the latest AERZEN development in the area of controls is AERsmart, which was designed as a global control system from the very beginning. Specially developed for the wastewater market, it represents the jewel in the crown of the innovative Performance3 world by providing additional energy-saving potential.

Performance3 describes the efficient operation of a group of three different AERZEN blower technologies: the Delta Blower, a positive displacement blower, the Delta Hybrid, a rotary lobe compressor and the Aerzen Turbo, a turbo blower or turbo compressor. The individual machines are optimised for various volume flow ranges. The developers' preliminary innovative idea was therefore to combine the various machine technologies for a needs-based and flexible utilisation of the various strengths of the machines with regard to energy efficiency. The Turbo is also described as a turbo machine and provides the most efficient performance close to its nominal point. Delta Hybrid and Delta Turbo are displacement machines – they provide good efficiency even under partial-load operation. Blower, Hybrid and Turbo can be implemented individually, in pairs or threes, as required. This optimises energy usage for each load requirement. The variable application of these various technologies has enabled energy savings of up to 30% to be achieved in wastewater treatment plants. The AERsmart control additionally increases the efficiency produced by the Performance3 combined operation: up to 15% from the application of this innovative control alone.

The AERsmart thus acts as a conductor, which in each case switches to the most efficient machine or the most efficient combination of machines. The performance range data of the assemblies and their efficiency are saved in the AERsmart algorithm. The intelligent evaluation of these details results in an active regulation of the integrated machine system. The coordination and control of up to twelve machines, also third-party models, is thus possible. The requested volume flows are distributed intelligently amongst the individual machines.

Furthermore, as with the AERtronic, it enables process data to be saved and analysed and transferred to other systems. While the AERtronic only controls displacement machines, i.e. blowers and compressors, the AERsmart also controls other technologies like the turbo blower.

How does this work? The oxygen quantity, compressed air and volume flow values required in the aeration tanks are transferred to the control as nominal value signals or via a bus connection. The AERsmart then selects the optimal machine combination from the group. In this way, the volume flow is always precisely generated in line with the load. The required air quantities are optimally distributed across the various technologies and their efficiency. This generates the oxygen supply in the aeration tank more efficiently than ever before – even with frequent changes in load, it produces a virtually perfect characteristic diagram.

AERsmart is available as a wall-mounted or console design. Since it always represents a central control and not an individual one, it is not built into a machine. A user-friendly interface and intuitive menu guidance enable simple installation. The high-resolution 12" touchscreen clearly displays the total process data and the data from the individual machines. The monitor can, for example, display the total air quantity and the differential pressure of recent days, detailed information on the individual machines, the utilisation per week, individual air quantity or pressure flow of recent days. In this way, the performance and life cycle of each compressor, as well as of the total machine park, can be monitored and analysed. Like the AERtronic, AERsmart therefore provides an unprecedented level of transparency regarding the total life cycle of the machine or the group of machines. The control communicates via analogue signals or bus systems, such as MODBUS, PROFIBUS or PROFINET. It can be networked with the process control and other systems. As with AERtronic, the application of AERZEN WebView enables remote diagnostics via an intranet or the Internet. What's more, just like the AERtronic, the AERsmart also has a comprehensive range of languages to choose from and in this way guarantees the secure use of the control all over the world.

With both the AERsmart and AERtronic controls, AERZEN has taken an important step in the direction of Industry 4.0 and the "Internet of Things". Both controls open up the opportunity for digitised, intelligent and resource-saving production as well as machine to machine communication.