Relubrication Device

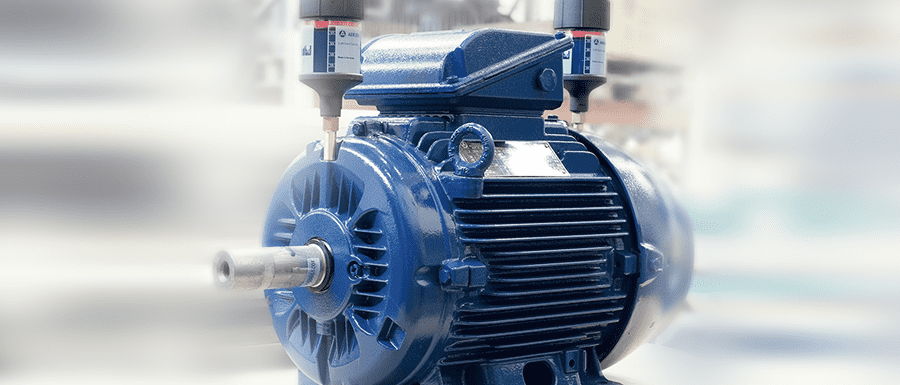

For automatic lubrication of electric motors

Technical data

| Designation | AERZEN Vario |

| Drive | Electromechanical / re-usable |

| Power supply | 4.5 V set of batteries, with a term of 12 months |

| Battery control | Yes |

| Dispensing time | 1 week up to 36 months |

| LC unit | 60, 120, 250 cm3 |

| Application temperature | -10° up to +60° |

| Pressure build-up | 6 bar |

| Type of protection | IP 65 |

| Setting of dispensing time | LCD display and pushbutton |

| Status control | Completely LED |

| Switch ON / OFF | LCD display and pushbutton |

Permanent lubrication AERZEN vario

The retrofit of the automatic, battery-operated AERZEN relubrication device AERZEN Vario is very simple: The programming is easy to understand and can be set up to 36 months and precisely adjusted to the actual grease requirement of the motor. In case of machine standstill, the facilities can be switched off and quantity adjustments are possible at any time. The assembly can be carried out up to 5 metres distance from the lubricating point. The preconfigured systems are supplied ready for connection and include all necessary fastening accessories.

Project planning

The following details are required for configuration of the AERZEN relubrication device:

- Details concerning the packaged unit

- Details concerning the operational mode of the packaged units

- Details concerning the motor used

- Determination of the grease requirement by means of the operating hours

The motor data of the electric motors used and the annual operating hours of the packaged units serve as a basis for project planning. From these values the required grease quantity is calculated. Various cartridge sizes make maintenance intervals from 1 month up to 36 months possible. The values for the WEG electric motors used by AERZEN are gathered in a data base and stored for the relubrication device.

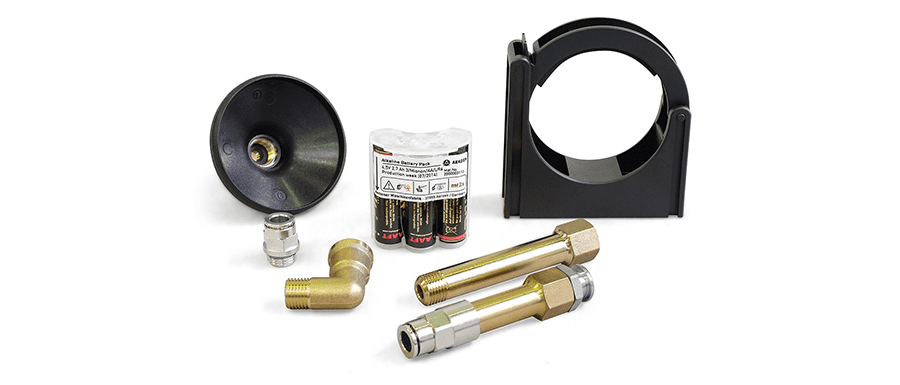

Service sets for AERZEN standard weg-motors

The “Service Sets” for AERZEN Standard WEG electric motors have been designed for retrofitting existing and for equipping new packaged units. Only the lubrication nipples must be removed. The material for connecting the regreasing facility to the AERZEN standard motor is included in Set I (attachment set motor regreasing). The regreasing facility itself consists of Set II (Drive set) and Set III (Service set).

- Extension

- Pipe reducer

- Swivelling screw-fitting

- Hose connection

- Heavy Duty hose

- Retaining clip for HD hose

- Mounting bracket

- Hexagon screw

- Washer DIN 9021

- Screw locking

- AERZEN Vario drive Gen. 2 version with special programming (36 months)

- Incl. supporting console

- Machine sticker battery and Cartridge change (service sticker)

| Cartridge | Grease type | Battery set | Yearly mark | Set No. |

| LC 60 | Polyrex EM / Shell Gadus S2 V 100 | Incl. | Incl. | 2000020070 / 2000020465 |

| LC 120 | Polyrex EM / Isoflex NBU 15 / Klüberquite BQ 72-72 | Incl. | Incl. | 2000020073 / 2000020071 / 2000020072 |

| LC 250 | Polyrex EM | Incl. | Incl. | 2000020074 |