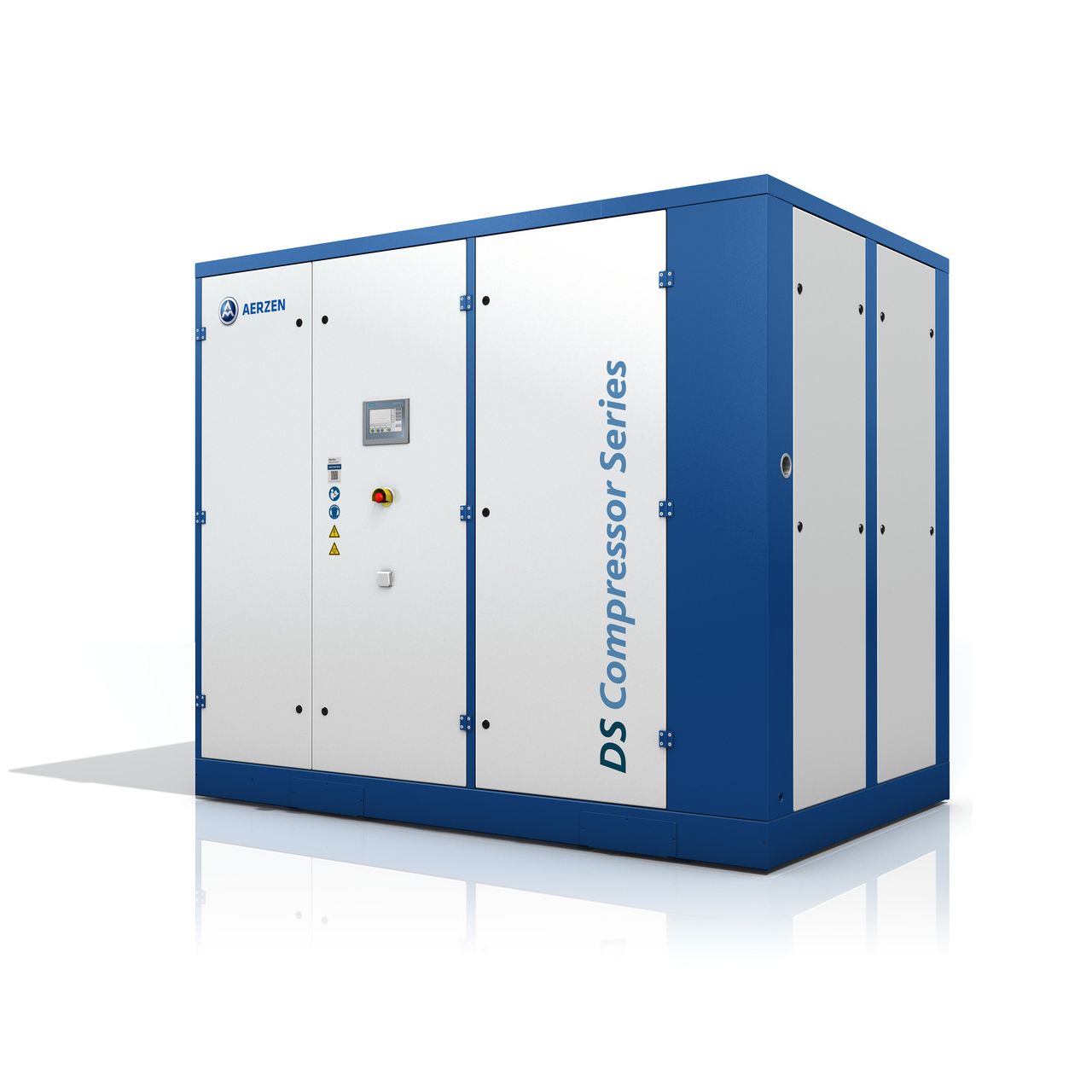

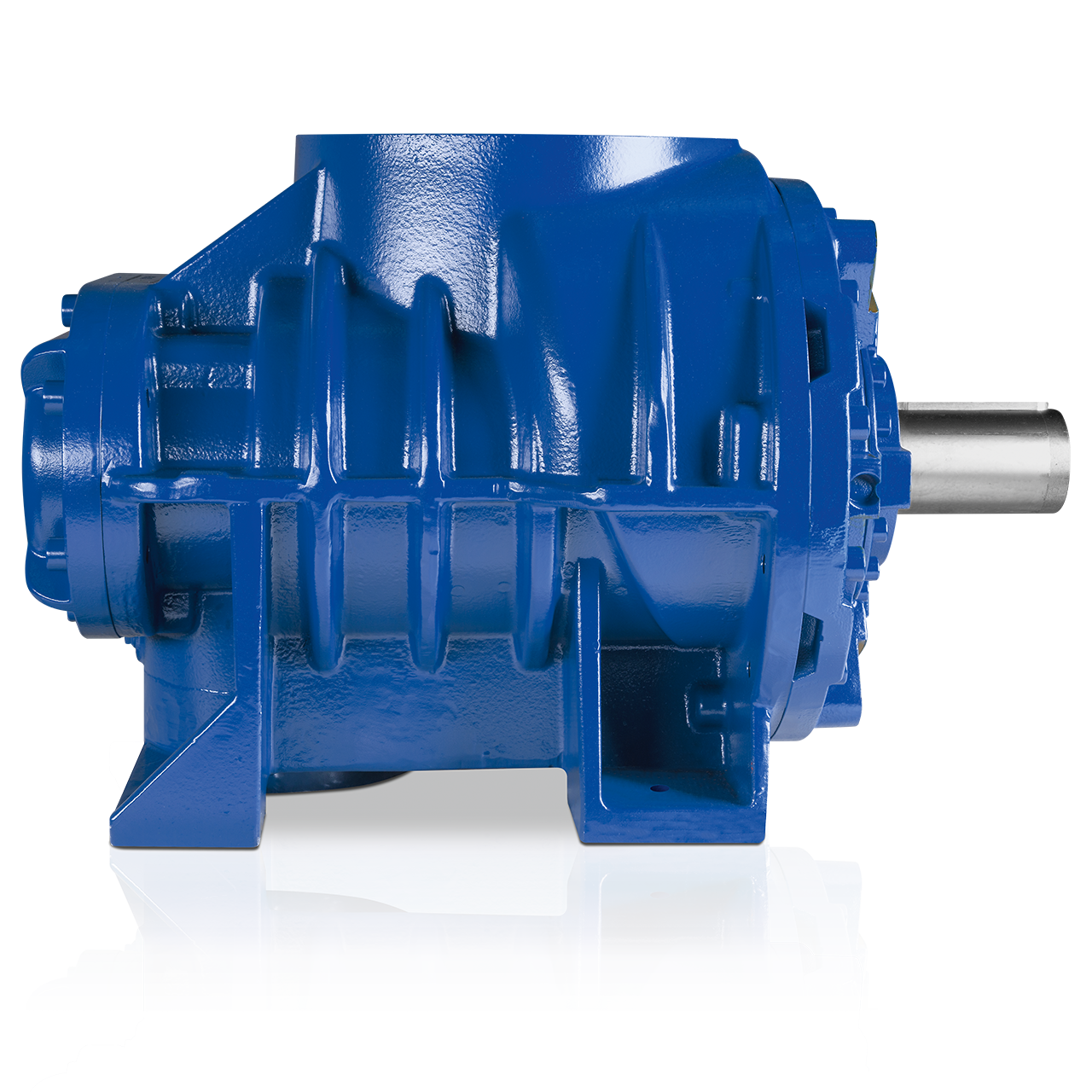

Compresores de tornillo

Ingenios universales

Versatilidad incomparable. Estas dos palabras concentran a la perfección lo que hace que los compresores de tornillo AERZEN sean tan especiales: admiten el mayor número de modificaciones posibles y se dispone de la más amplia gama de modelos y accesorios. Sin embargo, estas fases y series de equipos compactos tienen mucho más que ofrecer: nada menos que la capacidad de desarrollo del líder mundial del mercado, que trabaja constantemente en la innovación, optimización y ejecución de sus eficaces compresores desde 1943.

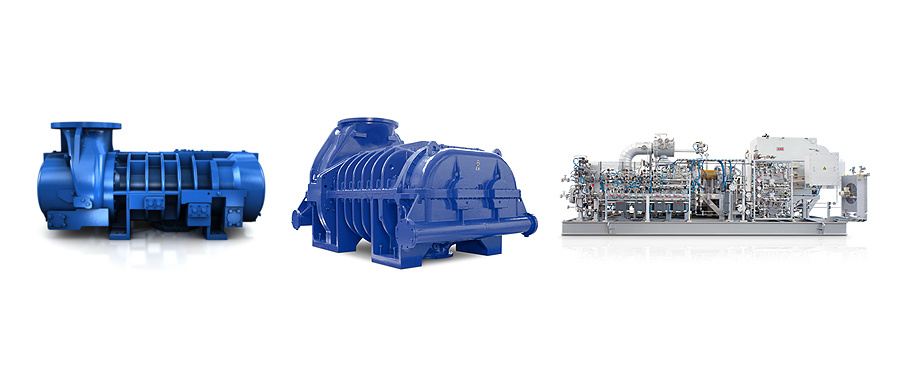

Liberar el potencial

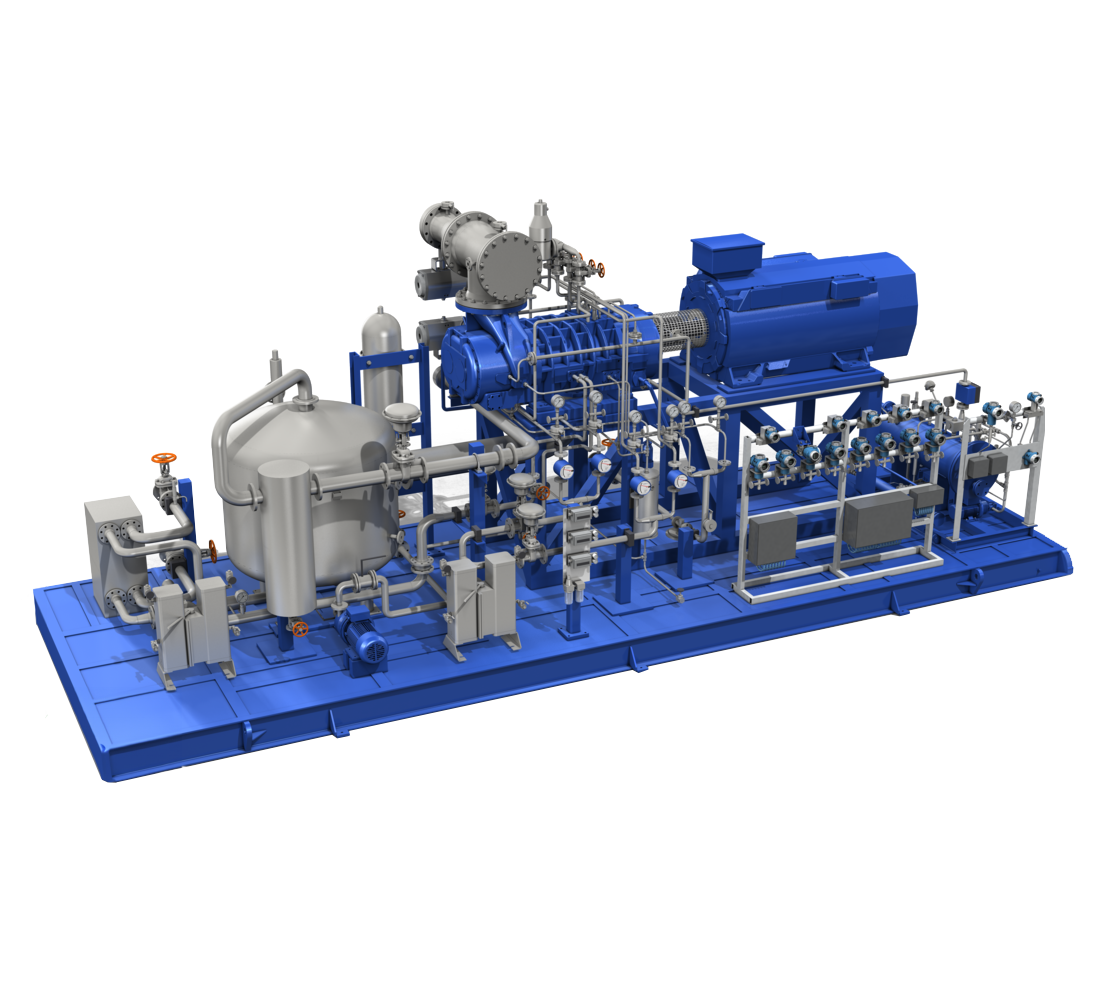

Durante décadas, los principales empaquetadores y usuarios industriales han insistido en las etapas de compresión y unidades empaquetadas AERZEN. ¿Por qué? Porque con su excepcional versatilidad estas máquinas son la solución ideal para cada aplicación. Originalmente diseñadas para comprimir aire, nitrógeno y gases neutros, estos genios polifacéticos también desarrollan sus puntos fuertes en el uso con gases especiales, en el funcionamiento en vacío y en aplicaciones de presión de entrada. Accionamiento directo y por correa, funcionamiento en seco y clasificados exentos de aceite hasta la clase 0 o con inyección de aceite, con o sin preentrada. Digámoslo así: AERZEN tiene el compresor adecuado para cada aplicación.

Los compresores de tornillo son máquinas de émbolos rotativos de doble eje. Funcionan basándose en el principio del desplazamiento positivo con compresión interna y se les denomina transportadores de fuerza. Así sucede en todos los compresores de tornillo. Sin embargo, lo que hace especiales a los compresores de tornillo de AERZEN es que hemos hecho de la fiabilidad, la facilidad de mantenimiento y uso, la flexibilidad y la eficiencia energética una cuestión de principios. El resultado es una variedad de características de diseño únicas. Consideremos los coeficientes de eficacia, por ejemplo los perfiles 3+4 de VML o 4+6 de VM de AERZEN. En comparación con los compresores estándar, ofrecen un ahorro de energía considerable. ¿Y qué es lo último en tecnología de compresores? Se trata de los nuevos compresores «E» de AERZEN. Con un incremento de la eficiencia de aproximadamente el 6 %, permiten liberar incluso un mayor potencial.

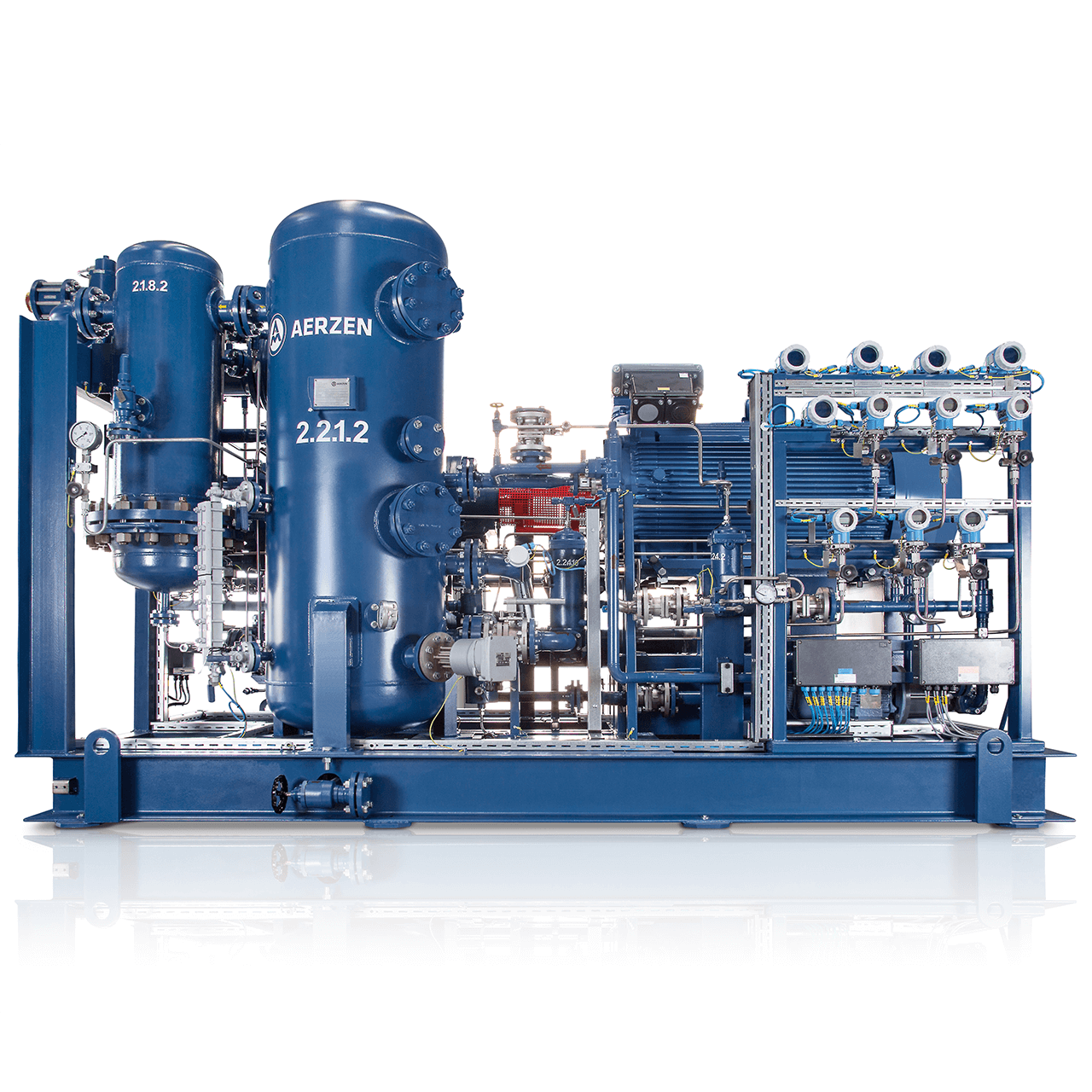

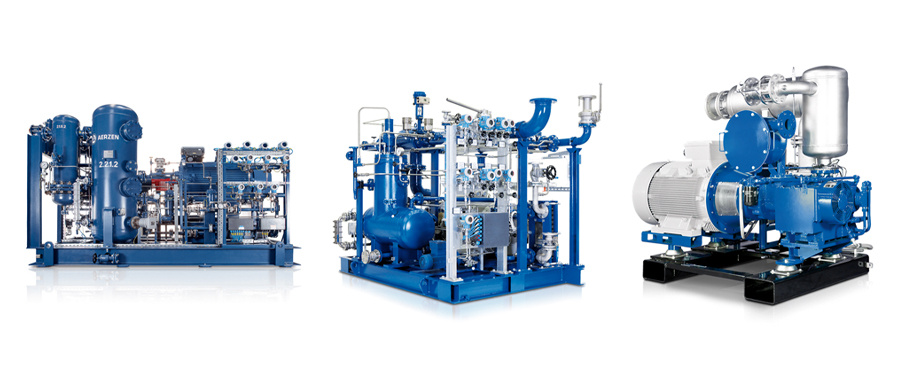

Compresores de tornillo exentos de aceite para las aplicaciones más exigentes

En los procesos de compresión de la industria, así como en la tecnología médica y alimentaria, a menudo es necesario comprimir el aire de forma que no queden residuos extraños en el aire comprimido. Los compresores de tornillo exentos de aceite son la opción ideal para ello, ya que no se introduce ningún material extraño en el aire comprimido. Muchos compresores de émbolos convencionales y compresores rotativos funcionan con aceite porque disipan mejor calor. Además, según el principio de construcción aplicado, el aceite sirve para sellar espacios. Sin embargo, para aplicaciones en las que la higiene es fundamental, la compresión debe realizarse sin aceite y también debe considerarse la posibilidad de agregar un filtro de aire comprimido. Así se garantiza que no queden residuos grasientos en el aire de alimentación. Estos sistemas también se denominan exentos de aceite. Los compresores rotativos son básicamente máquinas de desplazamiento que funcionan con dos rotores en forma de tornillo y que comprimen el aire mediante compresión interna. Este concepto no es nuevo, pero en términos de eficiencia energética, fiabilidad y facilidad de mantenimiento, las máquinas de AERZEN son únicas en su clase.

La eficiencia energética es cada vez más importante en los compresores de tornillo.

Los compresores de tornillo están diseñados como compresores rotativos. Estos comprimen el gas mediante la rotación de las palas entrelazadas dispuestas en forma de tornillo. De este modo, el espacio de compresión se reduce gradualmente y el volumen de gas se comprime. La producción fiable de aire comprimido es necesaria tanto en la industria como en las centrales eléctricas, así como en muchos otros sectores. Los compresores convencionales producen mucho más ruido que los de tornillo debido a sus diferentes principios de funcionamiento. Además, el desgaste de los compresores de tornillo suele ser menor. El resultado son unas máquinas robustas, fiables y de fácil mantenimiento para numerosas aplicaciones. También se distingue entre máquinas de transmisión directa y máquinas de transmisión por correa. Muchas empresas comerciales se pasan a los compresores de tornillo por motivos económicos. La eficiencia durante la compresión es especialmente alta, lo que repercute positivamente en el consumo de energía. En una época de altos precios de la energía, este es un aspecto muy importante, mientras que la cuestión de la recuperación del calor también desempeña su papel.

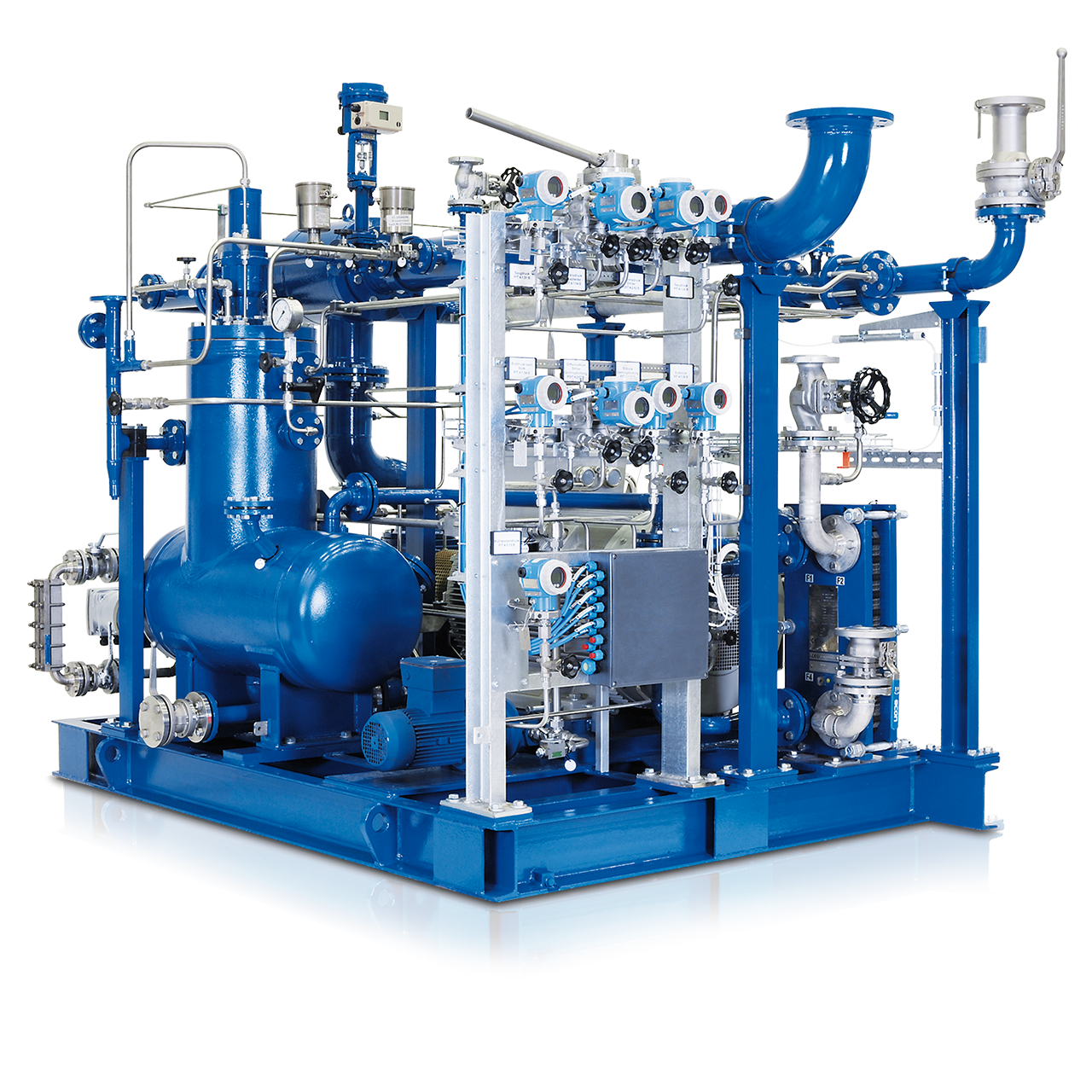

Los compresores de tornillo son polivalentes

Los compresores de tornillo requieren un mantenimiento extremadamente bajo porque tienen menos piezas móviles. Gracias a la ausencia de fuerzas de oscilación, las etapas de compresión son menos propensas a provocar grietas y otro tipo de desgaste. Los compresores de tornillo también presentan ventajas en cuanto a la eficacia de la compresión, ya que los compresores de émbolos pierden a través de los anillos de los pistones aproximadamente una décima parte del aire succionado. Los compresores de tornillo tienen una pérdida de presión significativamente menor y rara vez superan un valor del 0,1 – 0,2 por ciento. En cuanto a su construcción básica, los compresores de tornillo pueden considerarse superiores a los de émbolos y son mucho más eficientes. Permiten una gran reducción de los costes energéticos y de las emisiones de CO2 durante su uso. Existe otro potencial de optimización en el flujo del aire comprimido durante el proceso de compresión de tornillo. En caso necesario están disponibles motores superiores, los cuales ofrecen una mayor eficiencia energética, para dar respuesta a las exigencias de clase de eficiencia actual. En este contexto, la fiabilidad futura es especialmente importante para los clientes, ya que la longevidad viene determinada en parte si se podrá dar respuesta o no a los retos futuros de clase de eficiencia.

Menos vibraciones significan menos ruido

Hay compresores rotativos de uno y dos émbolos, pero cuando se habla de compresores de tornillo, lo que se suele entender son dos palas dispuestas en paralelo con tornillos de diferente perfil. Estas se engranan entre sí y comprimen el gas retenido en ellas. Si no se utilizan máquinas exentas de aceite, se inyecta aceite para refrigerar y sellar. Este procedimiento, denominado refrigeración de fluidos, se recomienda cuando las condiciones de funcionamiento exigen temperaturas ambientales más altas. El aceite también puede ayudar a minimizar el desgaste porque evita el contacto. Las construcciones de alta calidad exentas de aceite prescinden de esta medida y, gracias a los métodos de producción de alta precisión y los piñones sincronizados, prácticamente no presentan fricción y son absolutamente estancas. Una gran ventaja de los compresores de tornillo es su funcionamiento silencioso, A diferencia de los compresores de émbolos, no es necesario detener las masas en sus respectivos puntos muertos. Las vibraciones en el interior de un compresor rotativo se reducen de manera notable.

Perfecto aislamiento acústico con la optimización del control del flujo

La eficiencia energética de los compresores de tornillo se puede optimizar de diversas maneras. Se ha demostrado que las mejoras en la admisión de aire en el compresor son muy efectivas. En las máquinas de la última Generation 5 plus de AERZEN, todos los componentes están alineados con precisión para ofrecer un caudal óptimo. La reducción de las pérdidas de presión y la mejora de las aperturas de entrada y salida contribuyen a garantizar que el suministro de la presión final deseada permanezca estable y fiable. El aislamiento complementario, además de reducir el nivel de ruido durante el funcionamiento, también optimiza las condiciones del flujo. Con la aplicación de una innovadora geometría de aislamiento se reducen los niveles de presión acústica. Además, actúa como un eficaz extintor de chispas. Las máquinas provistas de esta característica también están homologadas para centrales eléctricas a prueba de explosiones. A pesar de estas características óptimas, para este aislamiento no se precisan materiales complementarios. No hay que preocuparse por la contaminación de los materiales de aislamiento dañados, etc. y los trabajos de mantenimiento correspondientes también se suprimen. Además de la necesidad de compresores exentos de aceite, un aislamiento efectivo sin riesgo de ningún tipo de contaminación es uno de los retos más importantes en áreas sensibles desde el punto de vista higiénico, como la industria alimentaria y las plantas químicas. Si es necesario, también se puede utilizar un filtro de aire comprimido para limpiar el aire usado. En campos médicos son habituales filtros especiales como estos para preparar el aire comprimido a modo de sistema de separación para otros residuos. Para evitar la humedad no deseada en el área de aplicación, los propulsores y secadores garantizan la eliminación eficaz de cualquier traza de humedad presente en el aire. Está garantizado que en la cámara nunca quedarán restos de grasa, lo cual homologa a los nuevos modelos como compresores totalmente exentos de aceite.

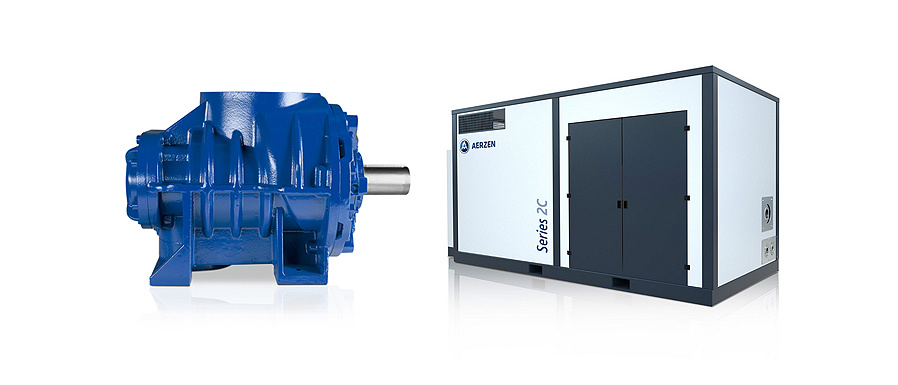

Fácil funcionamiento y posibilidades flexibles de reconversión

El funcionamiento cómodo de los compresores rotativos modernos no es un problema en la era digital actual. El funcionamiento y el mantenimiento son sencillos y reducen costes adicionales. La transmisión silenciosa de las máquinas mediante correa en la Generation 5 plus permite instalar diversas poleas de correa para conseguir la relación deseada. Hacer cambios tampoco es un problema. El compresor sigue siendo flexible en caso de que haya que cambiar los parámetros específicos y no se tiene que reemplazar con un modelo diferente con ajustes no flexibles. En la transmisión por correa el mantenimiento es extremadamente bajo porque está garantizada la tensión correcta por su propio peso. La velocidad de muchos dispositivos se puede controlar electrónicamente. La alta precisión y el cumplimiento exacto de la presión deseada son imprescindibles en la mayoría de las aplicaciones. En la carcasa se puede encontrar directamente un panel de control integrado. Gracias a la ubicación de los paneles de control en la parte frontal de los dispositivos, los equipos se pueden instalar de forma contigua para ahorrar espacio. También es posible verificar el aceite durante el funcionamiento. Los aceites especiales AERZEN aumentan el intervalo de cambio al doble de los valores prescritos.

La calidad es el criterio más importante

La alta calidad de los sobresalientes compresores AERZEN está reconocida a escala internacional. Los bajos costes de funcionamiento y la alta retención de valor van de la mano de una excelente fiabilidad y durabilidad para garantizar que el uso de los compresores rotativos modernos cumpla los criterios económicos y medioambientales más exigentes.