Pompy próżniowe

Technologia i zastosowanie

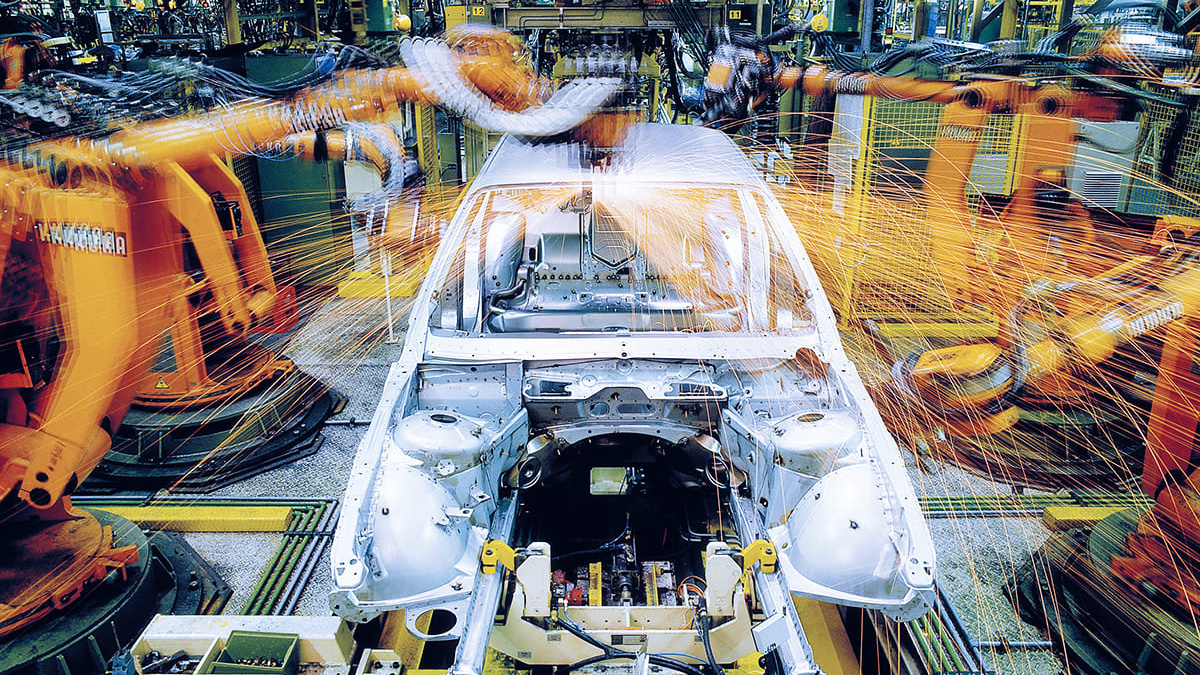

Przez technologię próżniową rozumie się wszelkie procesy prowadzone w warunkach gazowych znacznie poniżej ciśnienia atmosferycznego, czyli poniżej progu -700 mbar (podciśnienie) – co odpowiada wartości bezwzględnej 300 mbar abs. Firma AERZEN od lat czterdziestych XX wieku dostarcza przedsiębiorstwom na całym świecie niestandardowe rozwiązania w zakresie technologii próżniowej i produkcji. Oferujemy przemysłowe systemy próżniowe, takie jak pompy próżniowe i dmuchawy silnikowe, które są kluczowe dla tworzenia, utrzymania i pomiaru stanów częściowej i pełnej próżni. Naszym celem jest zapewnienie naszym klientom opłacalnej technologii próżniowej do wielu zastosowań dzięki wytrzymałym pompom próżniowym, które charakteryzują się mocą, trwałością i modułowością.

Rodzaje technologii próżniowej i ich zastosowania w przemyśle

Dostępnych jest kilka rodzajów pomp próżniowych i systemów dmuchaw, a dobór odpowiedniego sprzętu jest niezwykle ważny dla skonstruowania, konserwacji i ulepszania przemysłowych systemów próżniowych. Tego typu technologie są specyficzne dla danej branży; na przykład dmuchawy z pompami próżniowymi dla przemysłu stalowego mogą nie nadawać się do stosowania w branży lotniczej. Próżnia występuje w pięciu zakresach ciśnienia, mierzonych w milibarach lub torach (odpowiadających milimetrowi słupa rtęci lub mmHg):

- Niska: 1000 - 1 mbar / 760 - 0,75 Tr

- Średnia: 1 - 10-3 mbar / 0,75-7,5-3 Tr

- Wysoka: 10 - 10 mbar / 7,5 - 7,5 Tr

- Bardzo wysoka 10 - 10 mbar / 7,5 do 7,5 Tr

- Ekstremalnie wysoka: < 10-11 mbar / < 7,5-11 Tr

Różne rodzaje systemów stosowanych w przemyśle działają w tych pięciu zakresach podciśnienia. W AERZEN oferujemy wykonane na zamówienie urządzenia próżniowe, zaprojektowane tak, aby sprostać wymaganiom szerokiej gamy procesów przemysłowych dla klientów na całym świecie. Podzespoły naszych pomp próżniowych są zaprojektowane do wytwarzania, utrzymywania i pomiaru stanu pełnej lub częściowej próżni w celu zapewnienia optymalnej wydajności operacyjnej.

Ciśnienie powietrza odgrywa kluczową rolę w niezliczonych procesach produkcyjnych, technologii i różnych gałęziach przemysłu. W przemyśle metalowym, chemicznym, spożywczym i farmaceutycznym niezbędne jest niezawodne sterowanie wymaganym ciśnieniem. Technologia próżniowa zyskuje na znaczeniu; bez niej trudno sobie wyobrazić realizację wielu procesów i zapewnienie w nich zadowalającej jakości. Próżnia występuje, gdy ciśnienie atmosferyczne spada poniżej progu -700 mbar – co odpowiada wartości bezwzględnej 300 mbar abs. Przy wyższych wartościach mówimy o podciśnieniu.

Próżnia nie w każdej branży oznacza to samo. Zakres poniżej 300 mbar można rozbić na dalsze poziomy, zaczynając od średniej i wysokiej próżni, a kończąc na próżni ekstremalnie wysokiej. Próżnią doskonałą można byłoby określić ciśnienie bezwzględne 0,0000 mbar. Dodany termin „bezwzględne” odnosi się do próżni absolutnej i jest stosowany w technologiach próżniowych jako punkt odniesienia. Bez tak zwanych agregatów pomp próżniowych osiągnięcie tego zakresu nie byłoby możliwe. Od 1940 roku dmuchawy próżniowe firmy AERZEN uważane są za jedne z najbardziej niezawodnych w branży.

Jeśli chodzi o pompy próżniowe i sprężarki, to główna różnica polega na wyniku procesu; wytwarzanie próżni lub nadciśnienia osiąga się fizycznie podobnymi metodami. Sprężarka spręża powietrze zewnętrzne do zbiornika ciśnieniowego, natomiast dmuchawa odprowadza gazy na zewnątrz, usuwając w ten sposób gaz z dowolnego zamkniętego pomieszczenia. Stosowanie dmuchaw próżniowych nie ogranicza się tylko do zadań przemysłowych związanych z powietrzem, można je również stosować do wszystkich możliwych gazów. Należy również wiedzieć, że nie każda dmuchawa próżniowa nadaje się do dowolnych zastosowań i procesów. Ze względu na różne właściwości gazów i wielkości ich cząsteczek, technologia musi być zsynchronizowana z wykonywanym zadaniem.

Oprócz tego ważnym czynnikiem, jaki należy uwzględnić, są warunki środowiskowe eksploatacji dmuchawy. Trudne wymagania produkcyjne występują szczególnie w przemyśle chemicznym, farmaceutycznym i spożywczym. Istnieją również gazy, które są agresywne dla sprzętu lub nawet powodują zagrożenie dla zdrowia w zastosowaniach przemysłowych. Inne są niebezpieczne. Z tego powodu istotne jest, aby nigdy nie zaniedbywać prawidłowej separacji usuwanych gazów i ich właściwej utylizacji.

W zależności od żądanej wartości próżni, firma AERZEN ma w ofercie różne urządzenia, umożliwiające osiągnięcie i utrzymanie żądanych wartości. Firma AERZEN ma w asortymencie szeroką gamę urządzeń, które oferują odpowiednie rozwiązanie dla dowolnych wymagań.

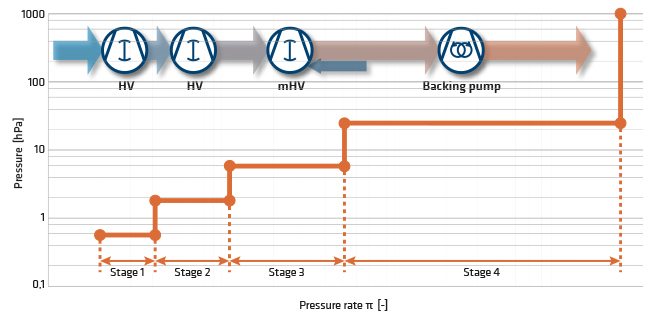

Dotrzymanie pożądanych parametrów dla konkretnych potrzeb w technologii próżniowej i wysokopróżniowej jest niezwykle ważne. Ważne jest również, aby wcześniej rozpoznać te potrzeby i zastosować odpowiedni sprzęt. Na przykład parametry wymagane w przemyśle stalowym znacznie różnią się od parametrów dmuchaw próżniowych stosowanych w innych miejscach. W zależności od potrzeb tzw. przepompownie pracują na kilku poziomach, przy czym z reguły wykorzystuje się więcej niż dwa poziomy. Bez takich przepompowni ekonomiczne wytwarzanie niskiej, dokładnej i wysokiej próżni nie miałoby sensu, a wręcz nie byłoby możliwe. Współdziałanie pomp wstępnych i dmuchaw rotacyjnych sygnalizuje zastosowanie przepompowni dwupoziomowych. Chociaż możliwe jest uzyskanie podciśnienia bezwzględnego w zakresie od 500 mbar do 300 mbar abs. na jednym poziomie, jest ono znacznie poniżej wymogu próżni i wymaga połączenia pomp wstępnych i próżniowych dmuchaw obrotowych. W tym przypadku pompa wstępna już na pierwszym etapie zmniejsza ciśnienie w danym zbiorniku lub pomieszczeniu. Następnie można włączyć dmuchawę rotacyjną, która w połączeniu z pompą wstępną może wytworzyć żądaną próżnię końcową lub przepływ objętościowy wymagany dla konkretnego zastosowania. Aby prawidłowo zaplanować jednostkę podciśnieniową, operator musi podać producentowi niezbędne parametry. Obejmuje to wielkość hali produkcyjnej, w której ma być wykonane podciśnienie, maksymalną wymaganą wartość próżni (lub przepływ objętościowy), a także maksymalny dozwolony czas odprowadzenia gazów – w celu właściwego rozproszenia. Mówiąc o maksymalnej wymaganej próżni należy również wspomnieć o punkcie pracy. W zależności od zapotrzebowania, odpowiednią pompę wstępną można połączyć z dokładnie dopasowaną dmuchawą próżniową.

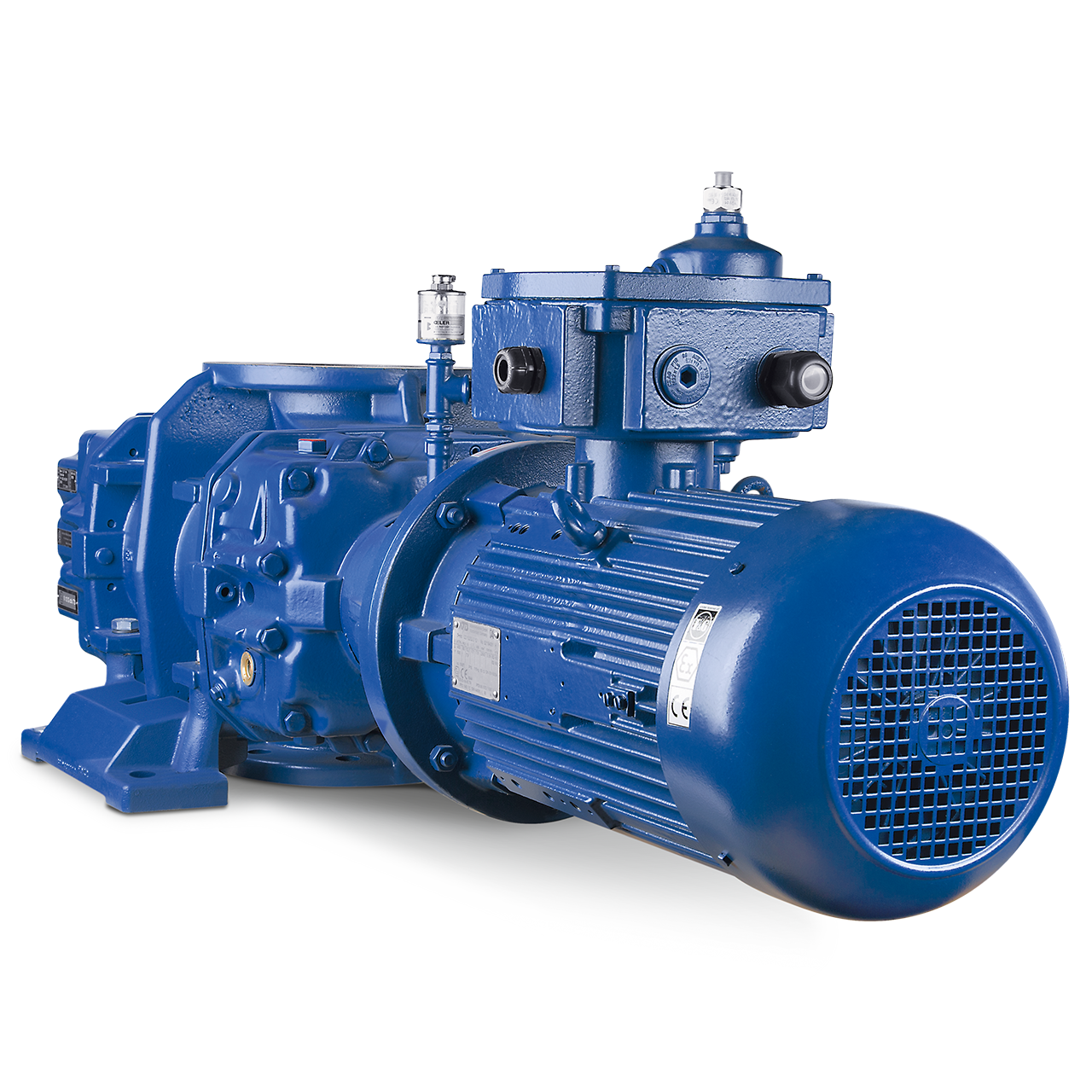

Większość systemów pomp wstępnych jest wybierana specjalnie pod kątem danych obszarów zastosowań. Dlatego dostępne są pompy z pierścieniem wodnym, smarowane obrotowe pompy łopatkowe lub regulowane pompy kłowe. Umożliwiają one łatwy transport gazów obojętnych. Zastosowanie śrubowych pomp próżniowych ma sens, gdy wymagania dotyczące odprowadzania są wyjątkowo wysokie. Podobnie jak sprężarki śrubowe, śrubowa pompa próżniowa pracuje bardzo równomiernie i precyzyjnie. Wysoka efektywność energetyczna, niski poziom hałasu i niewielkie zużycie przy wytwarzaniu próżni za pomocą śrubowych pomp próżniowych wiążą się zapewne z wyoskimi kosztami.

Niezależnie od tego, które rozwiązanie AERZEN wybierzesz do swoich potrzeb w zakresie wytwarzania próżni, wszystkie podzespoły pomp wstępnych i dmuchaw próżniowych będą do siebie doskonale dopasowane pod względem termicznym i energetycznym. W ten sposób firma gwarantuje bardziej niezawodny i trwały system pomp, przy jednoczesnym skupieniu się na efektywności energetycznej. W przypadku najbardziej rygorystycznych wymagań w technologii próżni przemysłowej zalecane są dmuchawy firmy AERZEN z obudowanym napędem. Są one najlepiej dostosowane do długotrwałej pracy i charakteryzują się krótkim czasem odprowadzania gazów. Oprócz kompaktowych wymiarów, dzięki którym tego typu dmuchawy idealnie sprawdzają się w połączeniu z dmuchawami dodatkowymi, są one dostępne w różnych konstrukcjach do różnych obszarów zastosowań. AERZEN oferuje CM do gazów agresywnych i HM do gazów obojętnych.

Firma AERZEN łączy i koordynuje własne produkty, aby sprostać specyficznym potrzebom swoich klientów i móc oferować rozwiązania dostosowane do indywidualnych potrzeb. Przy różnorodności możliwych zastosowań i wysokich wymaganiach nie jest możliwe po prostu sięgnięcie po gotowe rozwiązanie. Koncepcja i planowanie przepompowni to zawsze kwestia indywidualna. Tylko w ten sposób poszczególne urządzenia mogą być idealnie skoordynowane, umożliwiając tym samym uzyskanie pożądanych parametrów wydajności pomp wstępnych i próżniowych dmuchaw rotacyjnych. Profesjonalne i kompetentne doradztwo firmy AERZEN stanowi integralną część całej oferty. Aby zapewnić dotrzymanie wymaganych parametrów produktu końcowego, firma AERZEN prowadzi kompleksowe testy oprogramowania, potwierdzając w ten sposób nie tylko faktyczną wartość próżni, ale także długoterminową trwałość i parametry energetyczne. W ten sposób można uniknąć krytycznych zakresów ciśnienia termodynamicznego, które mogą stanowić problem podczas ciągłej pracy.

Szczególnie podczas długotrwałej eksploatacji ważne jest nie tylko dotrzymanie pożądanych parametrów wytwarzanej próżni, ale także uwzględnienie efektywności energetycznej. Pompy próżniowe są wyposażane w wysoce wydajną technologię, również ze względów ochrony środowiska. Zużycie energii jest szczególnie ważne w branżach o ogólnie wysokich kosztach energii. Dotyczy to zakładów produkujących stal – istnych pożeraczy energii. Co więcej, niezwykle istotne jest wskazanie urządzeń zapewniających redukcję kosztów i wysoką wydajność w oparciu o koncepcję przepompowni. Wszystkie urządzenia próżniowe firmy AERZEN są produkowane z najwyższą precyzją i spełniają najważniejsze standardy w zakresie optymalizacji energetycznej przy wdrażaniu systemów. Zgodność z tymi wartościami gwarantuje bezawaryjną, ciągłą pracę bez obciążania środowiska i budżetu.