Non-stop power - AERZEN screw compressors defy aggressive lime kiln gas in BernburgAERZEN at Solvay: an XXL overhaul

Around 35,000 m³/h volume flow, 2.7 MW drive power, 29 tonnes in weight: the VRO836 from AERZEN is a real giant. Its service life is also remarkable: for more than 25 years, the oil-free process gas compressor - incidentally one of the largest in the world - has been in operation at Solvay’s Bernburg soda works and delivers top performance every day. An overhaul of the XXL package is only required after five years of operation and is carried out within the scope of a regular maintenance interval. The result of the latest general overhaul, which was carried out by AERZEN service personnel on site at the customer’s premises: the machine is in top condition. This is not a matter of course, as the VRO836 is used in Bernburg for the pneumatic transport of lime kiln gas, which is highly corrosive - a major challenge for the materials and components.

Soda location with 140 years of history

The plant in Bernburg (Saale) is one of the oldest locations of the Solvay Group. Soda ash production began there as early as 1883. Today, the Group produces soda ash, sodium bicarbonate and hydrogen peroxide in Saxony-Anhalt - and is the world market leader in these products, which are indispensable in many aspects of daily life. They are used in the manufacture of glass, food, detergents and cleansing agents and also play an important role in metal processing, pharmaceuticals, the electrical and computer chip industry and environmental protection.

Soda is originally a natural product that was created by evaporation at the edge of salt lakes and was and is usually mined. Ernest Solvay, one of the two founders of the Solvay Group, succeeded in 1861 in developing a process through which soda ash could be produced inexpensively on an industrial scale. To this day, synthetic soda is produced worldwide using the Solvay process (also known as the ammonia soda process).

Quicklime and lime kiln gas are produced in the burner

The base materials for soda ash production are salt, limestone and anthracite or coke as well as ammonia, which is used as an auxiliary material. The limestone (calcium carbonate, CaCO3) that is processed at the Bernburg plant comes from a nearby open-cast mine and is transported from the extraction area to the plant site via an in-house plant railway. In the lime kilns, the rock is decomposed into quicklime (calcium oxide, CaO) and lime kiln gas, a gaseous mixture with a high carbon dioxide content (CO2). Although the lime kiln gas is only a by-product of the firing process, it is essential for the downstream processes.

Pneumatic transport of lime kiln gas

“We need lime kiln gas in a variety of applications as process gas. If it is not available in sufficient quantity and quality at the correct time, the entire soda production process comes to a standstill. It is therefore very important that the compressors we use for the pneumatic transport of the lime kiln gas achieve an elevated level of availability,” says Andreas Boinski, Head of Technology at Solvay GmbH in Bernburg. Sabine Zepperitz-Thews, Head of Technical Office, adds: “We have been working closely and confidently with AERZEN for many years. The company is simply the number one when it comes to large volume flows. The machines are robust, durable and absolutely reliable. This secures our production.”

Robust technology, reliable operation

The VRO series (today known as the VRA) which is used in Bernburg, is designed for the special requirements of process gas compression and is certified for plants in the chemical and petrochemical industry as well as many other ranges of process engineering. The machines compress and convey almost all gases occurring in the industrial range and are extremely reliable and efficient in operation. They often run flawlessly for decades with minimum maintenance costs. For operators, this means maximal process reliability and reduced investment and operating costs.

Oil-free compression for 100% product purity

VRO and VRA compressors are largely insensitive to contamination and polymerisation and enable particularly high pressure loads and rotor speeds. There is no meta contact in the compression chambers – neither between the two rotors nor between rotors and the housing. This ensures an absolutely oil-free working method, as the conveying chambers and thus the conveying medium - in this specific application the lime kiln gas - remain 100% pure. At Solvay, a labyrinth seal also ensures that the compressors are gastight. The bearings achieve a service life of up to 80,000 operating hours.

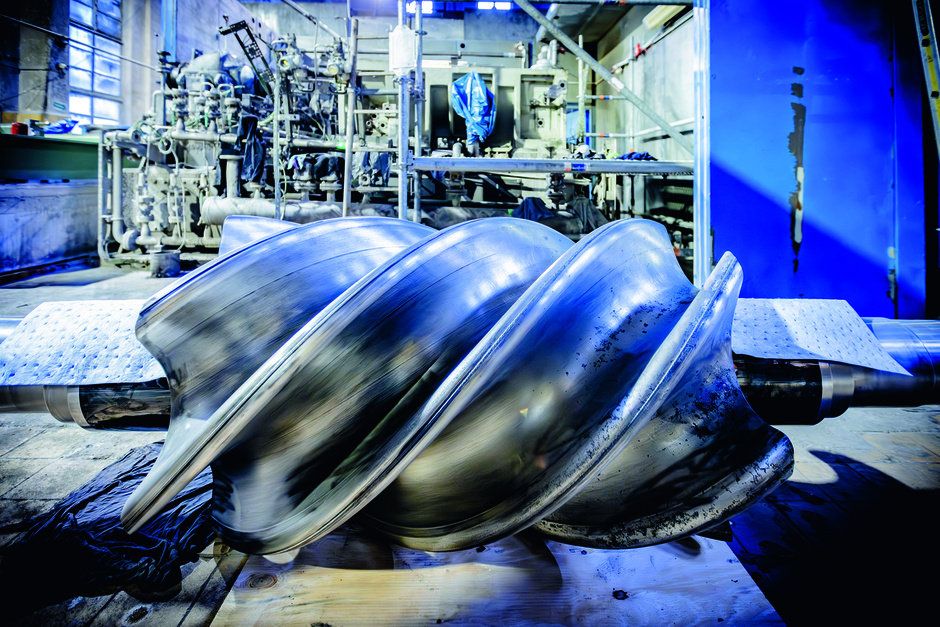

Overhaul of the superlatives

But even the best technology needs a check-up from time to time. Due to its enormous size and immense weight, the VRO836 was overhauled on site in Bernburg. The general overhaul was carried out by experienced service technicians from AERZEN. The technicians know the compressor inside out and specialise in getting the machine up and running again within the shortest possible period of time. “An overhaul is always a kind of grab bag: you never know what to expect when the machine’s internals are revealed.

With AERZEN, we have the expertise directly on site. Should problems occur, they can be quickly rectified. We can also exchange ideas and learn from each other. That’s great - particularly for our young colleagues,” says Thomas Bäuml, head of the main workshop in Bernburg.

Broken down into all individual components

The system was completely dismantled and broken down into its individual components. Everything was inspected, cleaned and, if necessary, repaired or replaced. Only AERZEN original spare parts were used. These are specially designed for AERZEN compressors and blowers and have optimum compatibility. This enables full functionality for smooth operation and a long machine service life. As a rule, repair and wear parts are available from stock for all standard products. A comprehensive network of service centres and decentralised parts warehouses secures short distances and fast reaction times. All valves and measuring equipment were also tested and recalibrated. The machine was then completely re-assembled and put back into service.

The condition of the compressor is impressive

The lime kiln gas in the Bernburg soda works is very corrosive and pushes many materials to their limits. The AERZEN screw compressor was not troubled by these adversities and presented itself in top condition: hardly any wear, no leaks, no bearing damage, best vibration behaviour, full reliability. “The condition of the compressor was excellent. That is really remarkable. We are delighted,” adds Thomas Bäuml. But how has the VRO836 been able to deal with the challenging conditions so well over the years? The robust design, the innovative technology, the resistant surface coating (chemical coating) and the use of a special material pairing of rotor and housing should be emphasised at this point. The regular maintenance and services from AERZEN have also played their part. Speaking of services: the services include quotations for every phase of a machine’s life and are customised precisely to the individual needs of the customers. The result: the highest possible machine availability and optimum cost efficiency.

Trusted cooperation

“We strive for high availability of our systems. That’s why it’s important to us that the result after the overhaul is virtually as good as new,” emphasises Andreas Boinski: “AERZEN is an excellent service partner. The overhaul was carried out competently and efficiently so that the compressor was ready for use again very quickly. The experienced technicians not only know their machines inside out, but are also very familiar with the conditions on site and our processes. That is very important to us and makes collaboration easy.” By the way, the VRO836 is not the only AERZEN compressor at Solvay. The entire group of companies trusts the compressor specialist's reliable technology and excellent service.