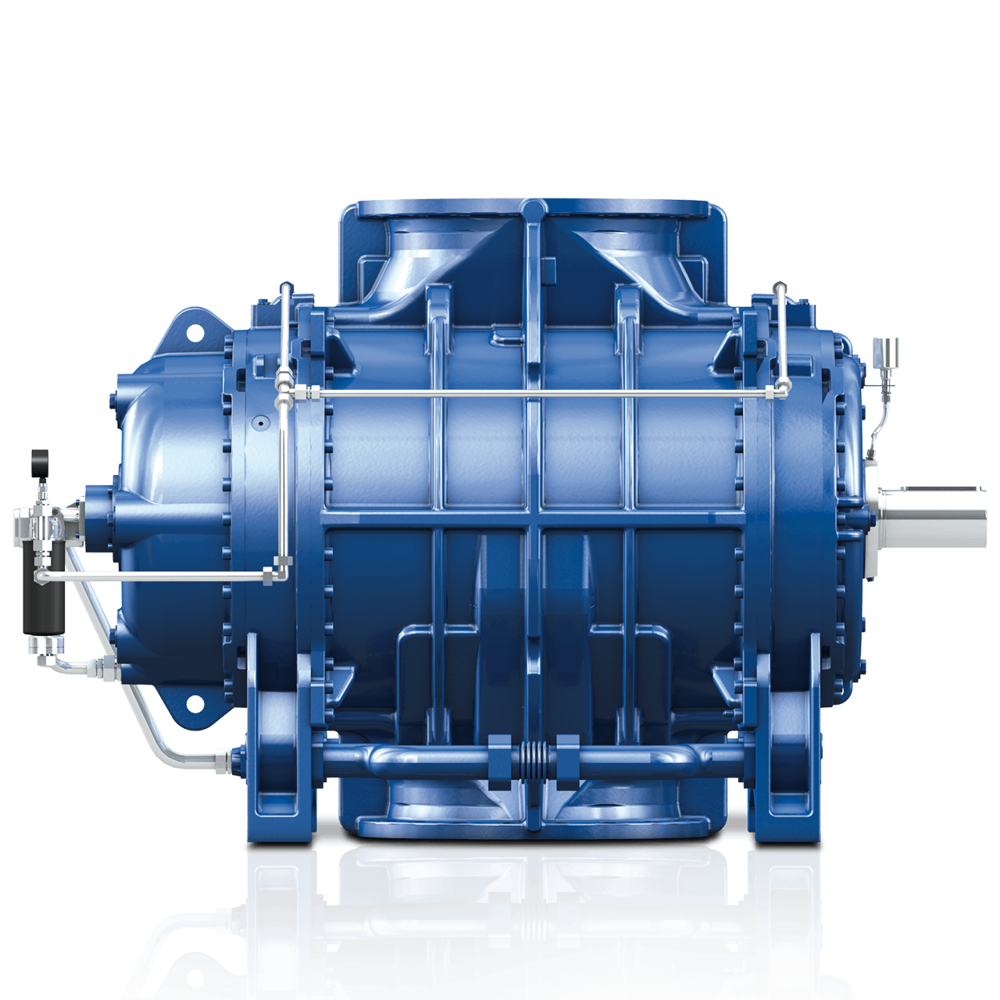

Soffiatori a lobi

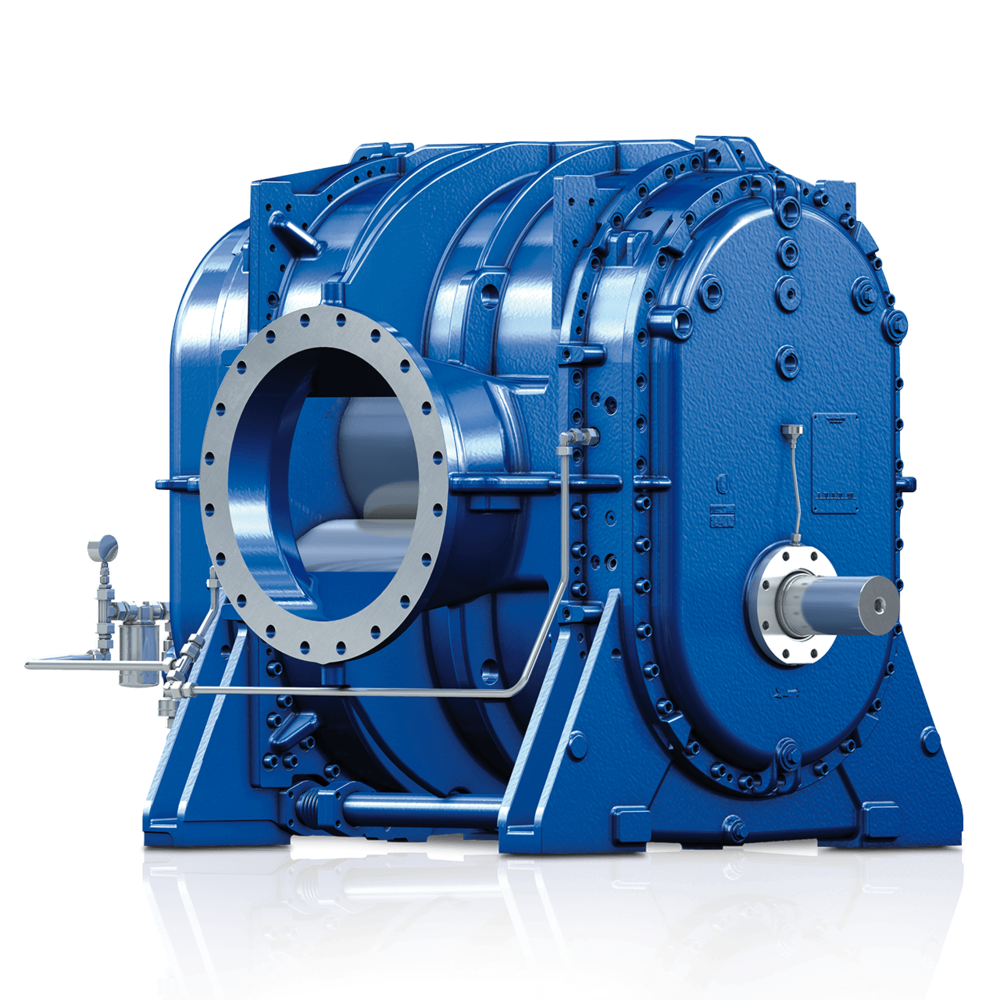

Soffiatore di grandi dimensioni

serie Alpha Blower

Alpha Blower: una vera soluzione a tutte le esigenze del cliente. Alpha Blower vuol dire affidabilità abbinata al massimo della precisione e del livello di sicurezza. Le ben note caratteristiche sono state ulteriormente migliorate senza trascurare gli aspetti di funzionalità all'interno di un impianto consolidato.

Portata:

9,600

-

77,000

m3/h

Pressione differenziale (Δp):

-600

-

1,000

mbar

Mezzo aspirato:

Aria,

Gas neutri

Funzionamento:

oil-free

Vantaggi di Alpha Blower:

- Regolazione della portata mediante sistema modulare - riduttore non necessario

- Forma costruttiva con rotori a 2 e 3 lobi. In base all'applicazione

- Flusso dell'aria orizzontale o verticale

- Costi di manutenzione ridotti

- Il concetto di affidabilità e sicurezza integrato

Alpha Blower - Perfetto per produrre l'aria di processo in modo sicuro ed efficiente.

Ovunque siano richieste qualità, affidabilità e sicurezza della macchina, ad esempio nel caso di processi critici o condizioni ambientali avverse, AERZEN offre soluzioni mirate per ogni singola applicazione.

Ad esempio, nel trasporto pneumatico: in molti casi, il trasporto di materiale sfuso viene effettuato mediante il trasporto pneumatico. Le macchine AERZEN più grandi vengono installate ad es. negli impianti di sollevamento. Sono in grado di scaricare navi da trasporto con una portata fino a 1.000 t/ora.

Ad esempio, nella produzione di ossigeno: i soffiatori in pressione AERZEN vengono impiegati per alimentare l'aria nei serbatoi dei filtri molecolari. L'evacuazione avviene per mezzo dei collaudati soffiatori per vuoto AERZEN. AERZEN Alpha Blower è la scelta giusta per aumentare la produttività e abbattere i costi di esercizio. Questo tipo di soffiatore è affidabile, capace di lavorare in continuo, consentendo di ottenere una produzione con elevate portate in modo sicuro ed economico.

Altri gas:

- Ossigeno

- Azoto

- Gas inerti

- Gas speciali

Campi di applicazione:

- Industria alimentare

- Industria chimica

- Industria metallurgica

- Industria petrolifera e del gas

- Settore navale

- Industria del vetro

- Industria cementiera

- Industria tessile

- Centrali elettriche

- Industria mineraria

- Trattamento delle acque

- Ingegneria meccanica

- Industria siderurgica

- Industria delle materie plastiche

- Industria della carta

US Units

No- Tecnologia

- Soffiatori a lobi

- Pressione differenziale (Δp)

- -600 - 1,000 mbar

- Portata

- 9,600 - 77,000 m3/h

- Mezzo aspirato

- Aria, Gas neutri

- Funzionamento

- oil-free

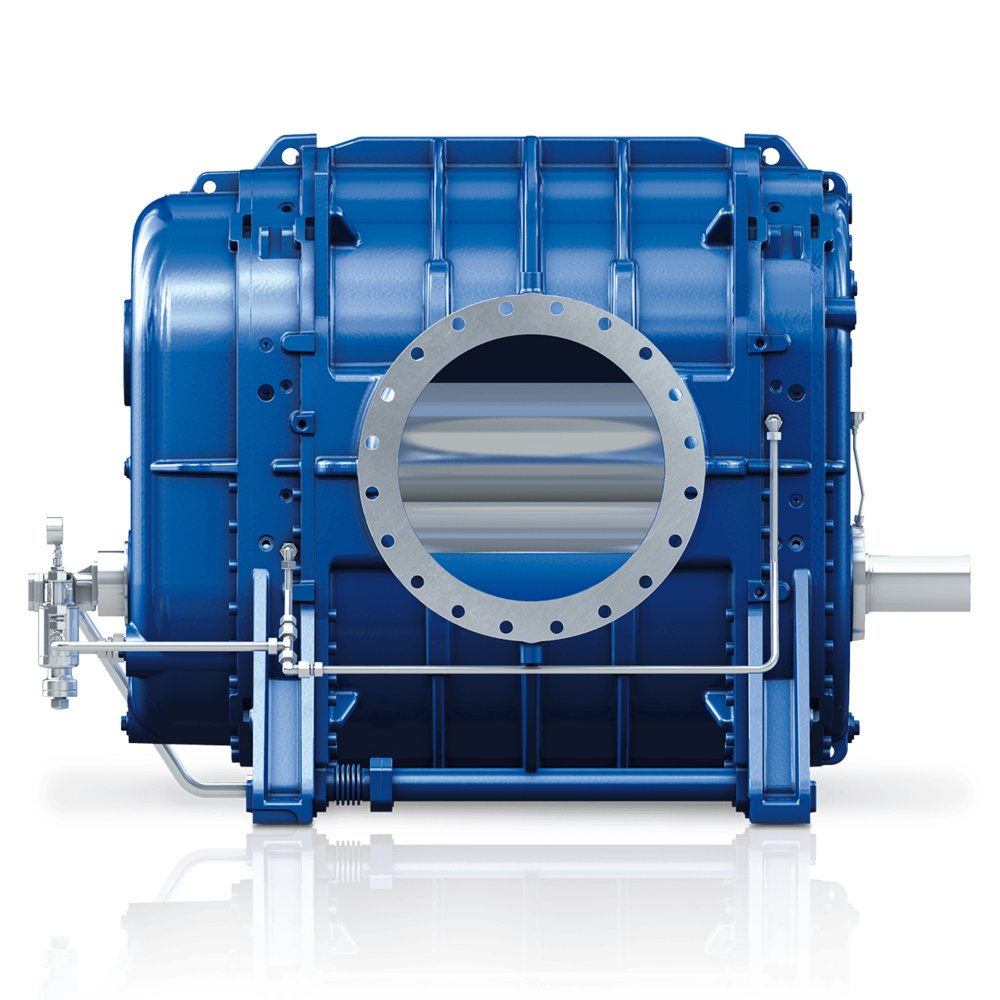

Individualità come sistema modulare. Per stadi e gruppi

La chiave per le soffianti di grandi dimensioni più efficienti prodotte da AERZEN è: È sempre la dimensione giusta. Ciò significa che AERZEN fornisce la soffiante della giusta dimensione per ogni singola applicazione. Grazie al nuovo sistema modulare Alpha Blower, per la prima volta è possibile scegliere tra 26 tipi diversi. Perfetto per un funzionamento sicuro e altamente efficiente delle vostre applicazioni di aria di processo.

Massime prestazioni con flussi di volume elevati. Affidabilità nella sua forma più elevata

Il soffiatore Alpha rappresenta la robustezza, combinata con la massima precisione e la massima sicurezza. Questo soffiatore è stato ottimizzato in termini di progettazione del flusso e di processi. Le note caratteristiche sono state ulteriormente migliorate senza trascurare il sistema collaudato. Le dimensioni finemente graduate supportano l'aumento dell'efficienza e gli sviluppi innovativi dei componenti. Soprattutto il basso consumo energetico è determinante. Ogni soffiante AERZEN è specificamente adattata al vostro processo e configurata di conseguenza: Pertanto, è sempre della misura giusta.

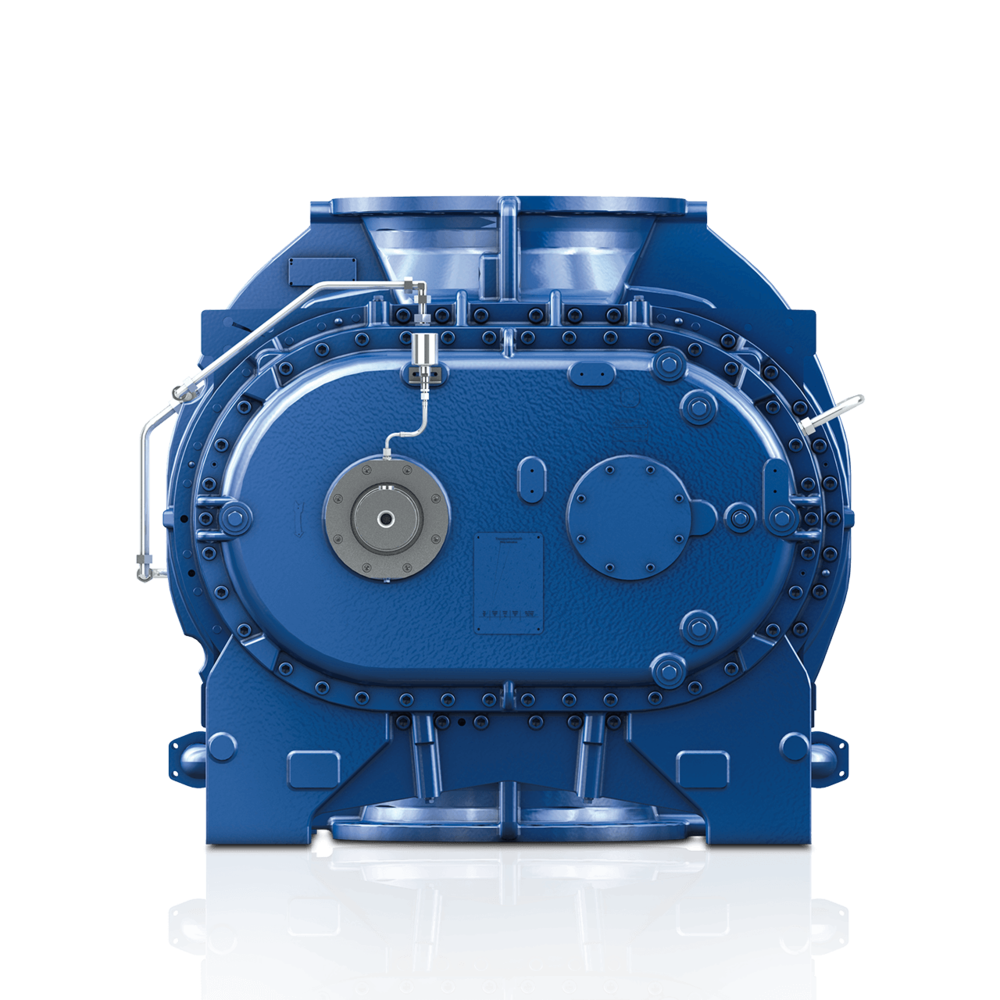

I vantaggi di Alpha Blower in sintesi:

- Gradazione del flusso volumetrico tramite sistema modulare - non è necessario un riduttore

- Disponibile con rotore a 2 o 3 lobi. A seconda dell'applicazione

- Direzione di trasporto orizzontale o verticale

- Manutenzione ridotta

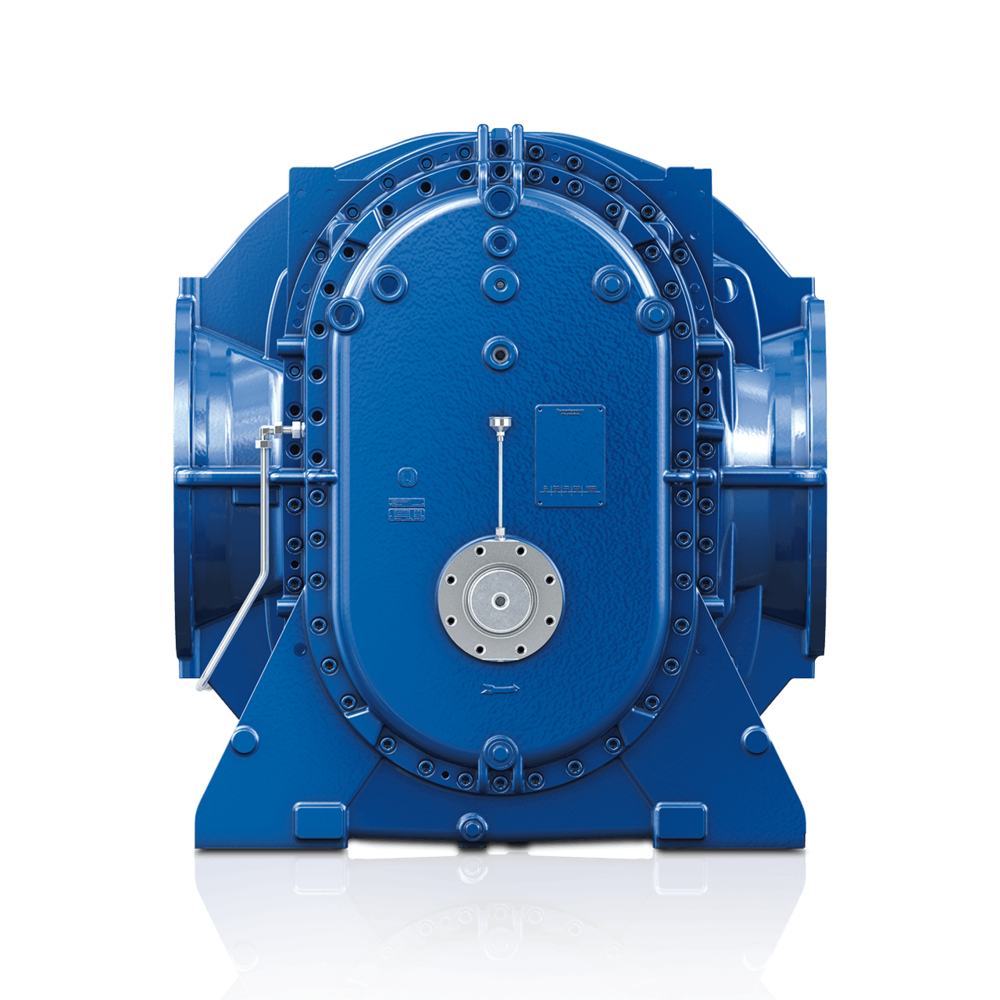

- Durata e concetto di sicurezza integrato

Possibilità di infinite modifiche. Modulare e totalmente personalizzabile.

Alpha Blower - più individuale che mai. Oltre alle diverse misure, numerose modifiche e un'ampia gamma di accessori completano il sistema modulare AERZEN. È così che AERZEN ti garantisce il massimo della personalizzazione. Queste opzioni fanno di Alpha Blower un vero e proprio fornitore di soluzioni, adatto a qualsiasi requisito dei clienti.

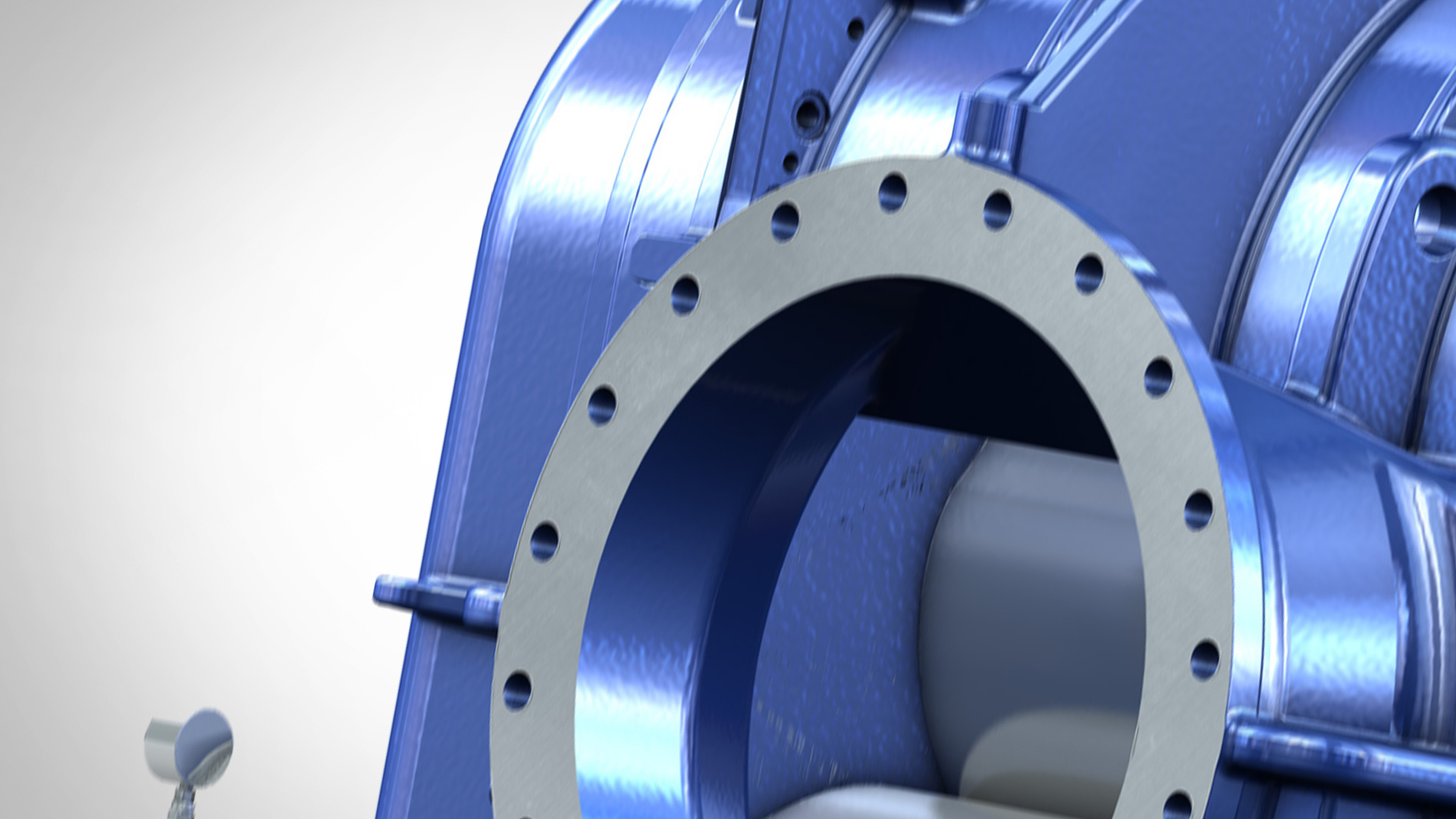

Alpha Blower è disponibile nella versione a 2 o 3 lobi.

Vantaggi della tecnologia a 2 lobi

- Alta efficienza alle pressioni negative

- Bassi costi di investimento

- Riduzione delle pulsazioni grazie all'ingresso morbido

Vantaggi della tecnologia a 3 lobi

- Basse pulsazioni nelle tubazioni

- Riduzione degli urti

- Alta efficienza in sovrapressione

- Assorbimento sonoro ottimizzato grazie al silenziatore più piccolo

Alpha Blower

L'elemento chiave che contraddistingue i soffiatori più grandi prodotti da AERZEN è: avere sempre le giuste dimensioni. Questo significa che AERZEN fornisce sempre soffiatori di dimensioni corrette per ogni singola applicazione. Grazie ad Alpha Blower, con il nuovo sistema modulare, puoi scegliere per la prima volta tra 26 tipologie diverse. Perfetto per produrre aria di processo in modo estremamente sicuro ed efficiente.