Turboblowers

Compact vermogen voor beluchtingstanks

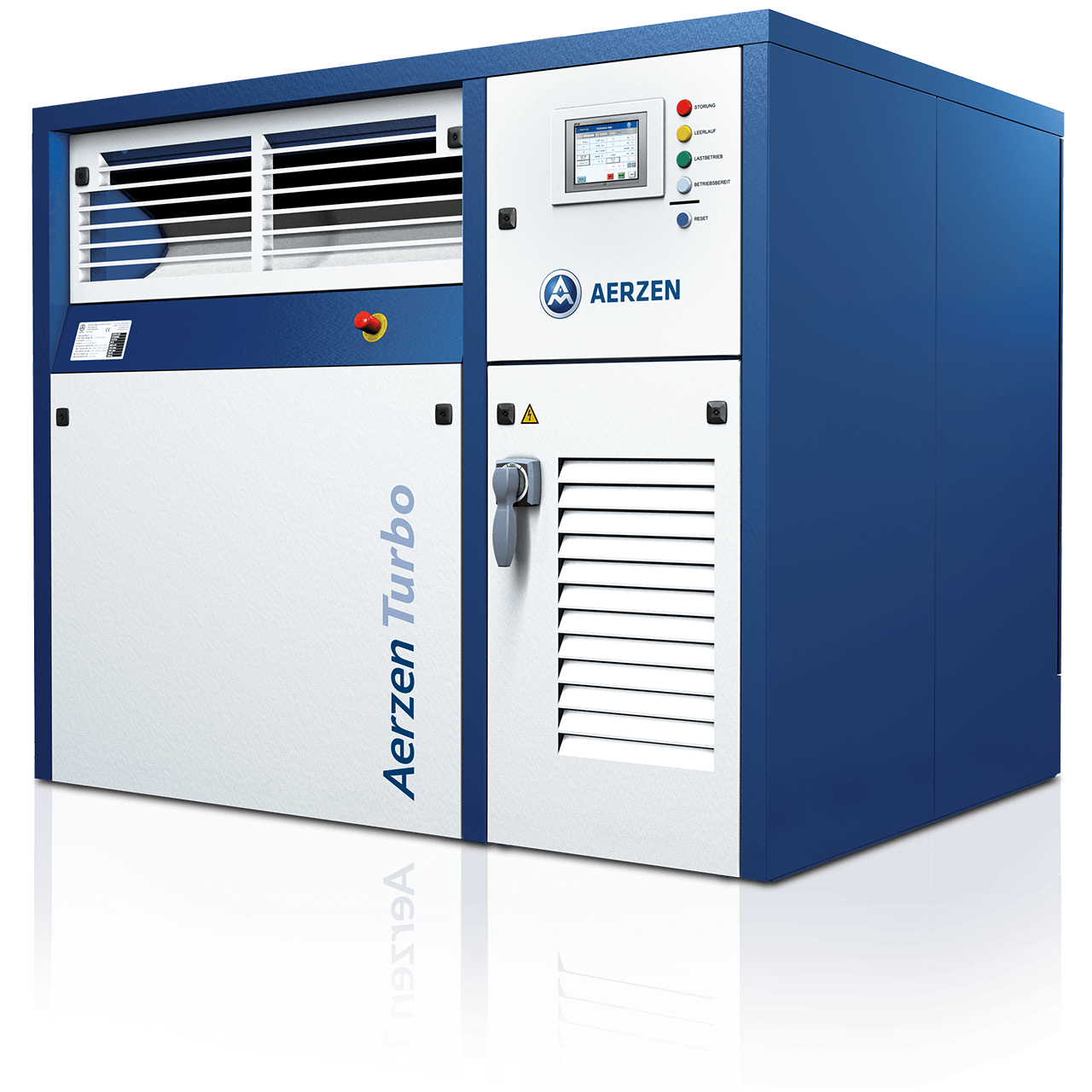

AERZEN is een van ‘s werelds toonaangevende fabrikanten van turboblowers. Sinds 1911 is het hun prioriteit turboblowers te bouwen die in het teken staan van betrouwbaarheid, energiezuinigheid en lage levenscycluskosten. Aerzen turboblowers hebben aanzienlijk minder ruimte nodig ten opzichte van conventionele turboblowers, en bieden betrouwbare prestaties en een hoge efficiëntie.

Beluchtingsblowers spelen een integrale rol in water- en rioolwaterzuiveringsinstallaties. De beluchting in een afvalwaterzuiveringsinstallatie is verantwoordelijk voor meer dan 50% van het totale energieverbruik en 75% van de levenscyclus van een turboblower.

Het benutten van de efficiëntie van een hogesnelheid turboblower of turbocompressor is een uitstekende manier om de operationele efficiëntie te verbeteren en energieproblemen in riool- en afvalwaterzuiveringssystemen aan te pakken.

Als u kiest voor een hogesnelheid turboblower om energie te besparen en uw CO2-voetafdruk te verkleinen, zijn AERZEN-turboblowers de beste keuze. Deze hogesnelheid turboblowers zijn speciaal ontworpen om te voldoen aan de eisen van biologische, industriële en gemeentelijke afvalwaterzuiveringsinstallaties en werken met een permanente magneetmotor.

Deze hogesnelheidsmotor is aanzienlijk efficiënter dan traditionele motoren voor afvalwaterzuiveringstoepassingen. Een volledig olievrij, contactvrij en trillingsvrij luchtfolielager helpt om de draaisnelheid van de luchtgekoelde hogesnelheidsmotor aan te drijven en aan te passen. Het resultaat is een uitzonderlijk hoge efficiëntie, lager energieverbruik, minder slijtage en lagere bedrijfskosten.

Het is essentieel om afvalwaterzuiveringsbeluchtingstanks te voorzien van een adequate persluchttoevoer. Operators kunnen dit bereiken met hoogrendement turboblowers van AERZEN. Deze snelle turboblowers hebben een relatief eenvoudige constructie - een aerodynamisch ontworpen waaier die direct op de motoras is geplaatst.

De waaier genereert volumestroom door in een spiraalvormige behuizing te draaien. Het grootste nadeel van deze technologie zijn de hoge rotatiesnelheden van 20.000 tot 70.000 omwentelingen per minuut (rpm). Standaard kogellagers of andere mechanische lagers zijn niet praktisch voor zulke hoge rotatiesnelheden omdat ze vaak een zekere wrijving veroorzaken.

AERZEN heeft een ongelooflijk eenvoudige oplossing ontwikkeld voor de snel draaiende turboblowers - luchtlagers. AERZEN turboblowers zijn uitgerust met contactloze luchtlagers in de radiale lagers van hun aandrijfas en in het druklager dat de axiale krachten absorbeert.

Wanneer de as draait, maakt deze gebruik van de natuurlijke onbalans wanneer de hogesnelheid turboblower start. Dit proces resulteert in een excentrische cirkelvormige beweging in de luchtspleet tussen de as en het lager, waardoor de lucht of het gas in de spleet wordt samengeperst. Naarmate de draaisnelheid toeneemt, positioneert de as zich in het midden en de luchtdruk van meer dan 30 bar houdt de as in een contactvrije positie.

Een onderhoudsvrije coating met twee elementen maakt de hogesnelheid turboblower compleet. De coating fungeert als wrijvingspartner tussen het gepolijste oppervlak wanneer de turboblower start en de luchtlaag vormt zich binnen milliseconden. De PTFE-laag biedt uitstekende glijeigenschappen zonder dat er een smeermiddel nodig is.

Een stalen plaat met een golvende vorm vult de smeerlaag van het luchtlager aan en absorbeert de trillingen, waardoor de behuizing wordt beschermd. In tegenstelling tot AERZEN gebruiken andere fabrikanten van turboblower magnetische lagertechnologie op hun blower- en compressorsystemen.

Hoewel magnetische lagers even efficiënt werken als luchtlagers, hebben ze tal van nadelen in vergelijking met de luchtlagers van AERZEN. Hun cirkelvormig geplaatste solenoïden vereisen een UPS (ononderbroken voeding) en een complexer systeem om een nauwkeurige regeling te garanderen.

Deze vereisten maken magneetlagertechnologie duur en is onderhoud nodig, waardoor de levenscycluskosten aanzienlijk toenemen. De topprioriteit van klanten die een turboventilator kopen, is echter het verkrijgen van hoge prestaties en efficiënte beluchting met minimale onderhouds- en bedrijfskosten.

Het complexe ontwerp van magneetlagers is gevoeliger voor problemen dan het eenvoudige ontwerp van het luchtlagersysteem. Luchtlagersystemen hebben geen mechanische, pneumatische of elektrische bediening nodig. Daarom is een turboblower of compressie-eenheid met dit lagersysteem energiezuiniger, kosteneffectiever en vraagt het minimaal onderhoud.

AERZEN gebruikt contactloze luchtlagers als standaardoplossing in onze AT-serie hogesnelheid turboblowers. Deze lagertechnologie heeft tal van voordelen ten opzichte van zijn magnetische en mechanische tegenhangers. Deze lagersystemen werken volgens een eenvoudig fysisch principe, wat de operationele efficiëntie verbetert en hoge energiebesparingen bevordert.

Aangezien het luchtlagersysteem geen externe hulpapparatuur zoals elektronische regelsystemen nodig heeft, heeft het lagersysteem aanzienlijk minder onderdelen. Door deze constructie is het minder gevoelig voor problemen dan andere lagersystemen die in hogesnelheid turboblowers worden gebruikt.

De steunlagers van de rotor zijn niet noodzakelijkerwijs luchtgelagerd. Bij een storing in het magnetische veld heeft de rotor van een turboblower met een magnetisch lager de steun nodig van mechanische steunlagers. Bij stroomuitval of andere extreme omstandigheden hebben magnetische lagers een extra batterijsysteem nodig om de lagers minstens 30 seconden van energie te voorzien, zodat de rotatiesnelheid kan dalen tot een snelheid die de lagers niet beschadigt.

Het batterijsysteem is niet onderhoudsvrij en kan defect raken bij hoge en lage omgevingstemperaturen of wanneer de magnetische velden falen. Het back-upsysteem van de magnetische lagers werkt alleen bij extreem lage snelheden. Dat betekent dat een turboblower met magnetische lagers zeer gevoelig is voor schade bij zeer hoge snelheden, zoals bij terugkerende stroomstoringen zonder voldoende opgeladen accusysteem.

Bovendien is het onmogelijk om een defect magnetisch lager of reservelagers ter plaatse te repareren. U zult de hele eenheid naar de fabrikant moeten sturen voor reparatie, wat resulteert in langdurige vertragingen.

Aan de andere kant zijn AERZEN contactloze luchtlagers aanzienlijk minder gevoelig voor schade veroorzaakt door extreme of fluctuerende bedrijfsomstandigheden. Een AERZEN turboblower met een luchtlagersysteem kan functioneren in extreme situaties, zoals plotselinge drukveranderingen.

Het luchtlager en zijn dempende veercomponenten in combinatie met een hoge-temperatuurcoating compenseren de plotselinge veranderingen. Zo blijft de turboblower veilig, efficiënt en betrouwbaar werken.

Bovendien zijn AERZEN-turboblowers uitgerust met een geavanceerd blowermanagementsysteem met een unieke stationaire functie die een veilige werking en energie-efficiëntie bevordert, vooral tijdens meerdere starts of stops. Met deze functie stopt de turboblower of compressor niet volledig. In plaats daarvan draait hij op een minimum toerentalbereik van 10.000 tot 12.000 rpm.

Dit snelheidsbereik bevordert het creëren van voldoende luchtvering en zorgt tegelijkertijd voor een minimaal energieverbruik (2-5 kW). Het hele proces helpt slijtage te voorkomen. Het is vermeldenswaard dat u de turboblower volledig kunt stoppen in geval van langdurige stationaire werking.

Om de optimale efficiëntie en betrouwbaarheid van een turboblower te behouden, raadt AERZEN aan om het lagersysteem na ongeveer 80.000 bedrijfsuren of tien jaar te inspecteren. Bij het repareren van turboblower met luchtlagersystemen kunt u alle gerelateerde componenten binnen enkele uren ter plaatse vervangen.

Als u op zoek bent naar een snelle turboblower die energie-efficiënt is, gemakkelijk te onderhouden is en lage operationele kosten heeft, dan bent u bij AERZEN aan het juiste adres. AERZEN maakt gebruik van moderne technologie in het ontwerp van onze blowers om een uitstekende energie-efficiëntie te garanderen, wat leidt tot efficiëntere beluchting in afvalwaterzuiveringsinstallaties en andere gebieden van afvalwatertechnologieën.

Vergeleken met debietmachines van andere fabrikanten zijn de turboblowers van de AT-serie ook geschikt voor SBR-systemen (Sequencing Batch Reactor). Dit is te danken aan hun regelbereik en de optie voor stationaire werking. De stationaire modus biedt een hogere energie-efficiëntie dan het voortdurend in- en uitschakelen van de hele turboblower.

AERZEN beschikt ook over een geavanceerd blowermanagementsysteem dat gebruik maakt van het Venturiprincipe. Dit systeem toont u de hoeveelheid lucht die uw turboblower op elk moment levert. U kunt de prestaties van uw blower verbeteren op basis van de vastgestelde waarden, waardoor u energie bespaart en uw CO2-voetafdruk op de lange termijn verbetert.

Welke turboblower of compressor u ook kiest voor uw afvalwaterzuiveringsinstallatie, u bent verzekerd van kwaliteit. AERZEN turboblower en turbocompressoren zijn vervaardigd met de hoogste kwaliteit en getest om een lange levensduur, efficiëntie en verhoogde betrouwbaarheid te garanderen.

Aarzel niet om contact met ons op te nemen als u meer informatie wenst over onze turboblower of andere producten.