Water and Wastewater Treatment

Efficient solutions for municipal and industrial wastewater treatment plants

AERZEN is an internationally leading supplier in the field of wastewater treatment. For more than 150 years, we have accompanied operators of wastewater treatment plants and industrial partners with innovative solutions and can rightly claim: We know what to do. How can energy costs be saved in wastewater treatment? What possibilities are there for the design of new plants? How can load profiles be determined and optimally operated? AERZEN provides the right answers with its versatile and flexible solutions, as well as the experience from countless implemented projects.

Ask us, we are happy to share our experience - LET'S TALK!

Information & Documents

Case Studies

In our more than 150-year company history, we have acquired extensive know-how as a manufacturer of blowers and compressors. With this bundled know-how AERZEN is currently represented in more than 100,000 wastewater treatment plants worldwide and delivers custom-fit, highly efficient solution concepts for the wastewater market. See for yourself!

Suitable Products

for Wastewater Treatment Plants

Control Technology

Convenient, safe and efficient control

Wastewater Treatment

How can you save money on energy costs with wastewater treatment? What are the possibilities for a new facility design, replacing old models and components, or modernizing? These are important questions for every operator of any wastewater treatment plant. AERZEN can answer all your questions with its versatile and diverse solutions.

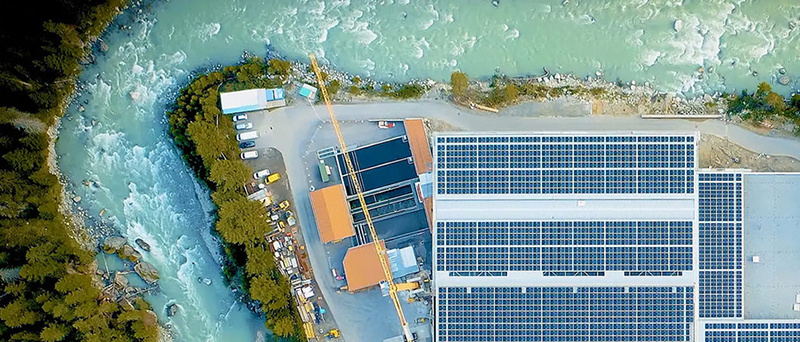

AERZEN is a leading international supplier of solutions for wastewater treatment and purification. Wastewater treatment in sewage plants is one of the largest fields for AERZEN blower technology. Compressors, blowers, and turbo blowers ensure the ventilation of the ventilation tanks in all types of sewage treatment plants. The application ranges from the small biological sewage treatment plant to larger plants, which are responsible for wastewater treatment in several municipalities. The machines from AERZEN enrich the wastewater by supplying compressed air with oxygen. The necessary oxygen is then fed to the bacteria, which enables them to degrade and eliminate waste particles in the ventilation tank in a biological way. This step of wastewater treatment takes 60 - 80% of the total energy costs of the sewage treatment plant. With this large chunk of energy costs, one can assume that a lot of money can be saved by using the most efficient technology available.

Regarding this energy technology, another important step for better efficiency is to monitor and optimize your daily and yearly fluctuations. An example would be the energy expenditures for the aeration of an active sewage treatment tank at a popular holiday resort; on a warm summer day with much higher volume, versus a cold day in winter. If the performance of the blowers can be tuned and adapted to these fluctuations, you can save a considerable amount of money and energy. To achieve this, it is worth taking closer consideration of each and every situation. How large is the wastewater treatment plant, are there large fluctuations, and/or is the workload evenly distributed? Are all the blowers at the optimal output, and do they match the control rate and the workload rate of the sewage treatment plant? How much space is available for the blower? How much longer will the facilities last, and when will it need a major overhaul? Basically, every sewage treatment plant needs to draw up some precise plans.

Positive Displacement Blowers (Rotary Piston Blowers)

Rotary piston blowers (e.g. the AERZEN Delta Blower) are the workhorses of the blower solutions. With relatively low initial costs, they can cover large control areas and offer a possibility of flexible applications. Rotary piston blowers can adjust pressure and temperature fluctuations with ease.

The use of positive displacement blowers is, by far, the most widely used in wastewater treatment. The remarkable flexibility within the control range can be easily realized with a frequency converter. Thus, consistency is produced even with fluctuations in capacitance. The comparatively low investment costs pay for itself in very little time.

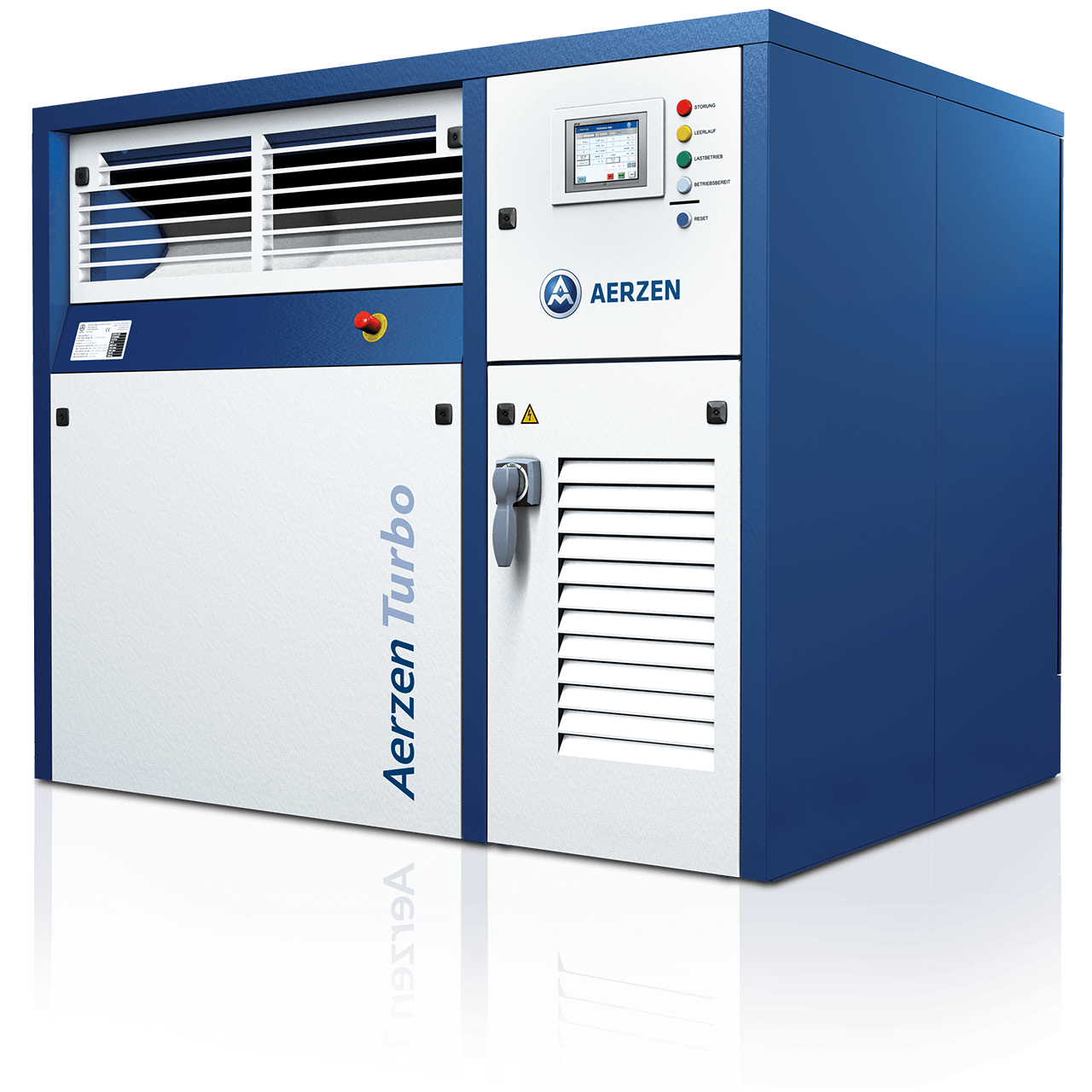

Turbo Blowers or Turbo Compressors

Turbo technology is often the most efficient solution for a process with a restricted, yet consistent control range and speed. With continuous operation close to its design point, the energy saved by the turbo is substantial compared to rotary piston blowers. The higher costs associated with the purchase will be easily offset by the turbos’ efficiency. The use of turbos is less suitable in a system with frequent extreme pressure and flow fluctuations.

Another advantage of the turbo is its smaller size. It requires a smaller installation space, which allows a more flexible use of blower space (e.g.: for retrofitting or redesigning the system). This can also reduce costs. AERZEN supplies the turbo and the other components as a package: the motor, blower and control are supplied as a complete machine and simple installation.

Hybrid Blower (Rotary Piston Compressor or Rotary Lobe Compressor)

A Hybrid Blower combines the best features and advantages of Rotary Blowers and Screw Compressors, with the efficiency of the Turbo Blowers. The main structural difference is the use of a low-pressure Screw Rotor instead of a straight or lapped rotary piston rotor. As a result, high flow and pressure fluctuations can be controlled flexibly and efficiently. Hybrid blowers offer a similar control range as positive displacement blowers and guarantee a relatively consistent volume of pressure changes. A Hybrid Blower has a control range of 25 to 100%. The advantage over Turbo Blowers is the superior efficiency in the partial load areas of the machine.

The installation of a combination of the above-mentioned machine- technologies is quite worthwhile in large sewerage treatment plants or large capacity and high fluctuation plants (e.g.: turbo compressor is used for the basic load and a hybrid blower is switched on for the peak load or low flow conditions).

The different types of machines can be used equally in the sand catchers and in the ventilation tank. A combination of turbo bowers, rotary lobe compressors, and rotary piston blowers can improve energy efficiency and substantially reduce the operating costs of the wastewater treatment plant. AERZEN offers solutions with its concept "Performance³".

The first is the intelligent AERZEN Performance³ software "AERsmart", which selects the most energy-efficient machine combination for every required operating point, guaranteeing that all machines will operate at their ideal with maximum efficiency.

The applications in wastewater technology are diverse. To assist in identifying the most fit and efficient system, AERZEN offers its customers a special assessment, the “AERaudit”, with which performance data of an existing system are measured and evaluated. Based on this analysis, improvements and energy-saving possibilities can be determined for each customer’s installation. Additionally, AERZEN has compiled a comprehensive assortment of materials for planning the sites for its customers. In addition to numerous product and planning information, plant engineers, engineering firms, and operators of sewage treatment plants will also find help calculating operating data, important information on machine room design, and tips for the possibility of heat recovery during treatment of wastewaters.

Numerous user feedbacks and reports in the field of wastewater purification illustrate, for example, how efficient solutions for very different needs are created with the appropriate use of different blower components.

Thus the efficiency of the Silverstone Sewage Treatment Plant in Colorado, USA, which was built in 1974, and which is responsible for wastewater purification and treatment in several municipalities - including holiday resorts with high fluctuations in demand – has been clearly improved by replacing the old centrifugal blowers with AERZENER Blower technology and additional frequency converters.

The AERZEN Turbo TB 100 (used here) is equipped with a permanent magnet motor, which has been specially developed for the high frequency and high-speed requirements of a directly-driven turbo application. As a result, the noise level has been drastically reduced and hearing protectors have become unnecessary. Additionally, the hot air from the cooling system of the fan can be used in winter for heat recovery, thus heating the system.

But also numerous success stories from the surrounding area speak for the quality and profitability of AERZEN products: In the Emsbüren Sewage Treatment Plant in southern Lower Saxony (Germany), an air-bearing turbomachine from AERZEN has replaced a magnet-bearing turbo of a competitor in March 2016. The turbo of the Series TB50-0.8 S covers the medium and high load operation of the plant designed for 16,000 EEC. The low-load operation at night is covered by a Rotary Piston Blower. The AERZENER Turbo is operated intermittently.

During start-up, the air bearing turbo initially starts in full-load operation, and maintains this operation for 10 minutes. Subsequently, 60% -70% of the maximum volume flow is reduced for a period of 60-80 minutes. Once the required oxygen reached the aeration tank, the turbo is initially switched to idling and then completely turned off. Through the intermittent operation with the appropriate shutdown processes, it became possible to adapt to different load requirements and to save energy. Based on good customer rapport with the air-bearing turbo from AERZEN, it was Lingener Land water board’s responsibility to replace a magnetic bearing machine with an air bearing turbo from AERZEN in the Spelle waste water treatment plant.

Another AERZEN success story in Germany is the Holzkirchen Wastewater Treatment Plant near Munich. 80% of the total energy costs of the waste water treatment plant are generated here for the drive of the blowers. Therefore, a tailor-made design and increases of impact turned out to be profitable very quickly. For the changing air requirements in the aeration tank, an exact air-dimensioning with an exact regulation was needed. In the AERsmart control of AERZEN a suitable answer was found. Based on the air requirements, this coordinates different blower types. Like an autopilot, the AERsmart adopts the control and regulatory management of the units, with different operating principles and implementations in-line with the requirements. The basic load is provided by a TB75-0.8S Turbo Compressor. In the case of peak loads, a rotary piston compressor of the Delta Hybrid Series is additionally used, with two Delta Blowers of the older type, taking over the air supply when the load is low. Partial loads within the facility are largely avoided by the targeted control and the differentiated use of the individual machines. At the same time, energy efficiency increases. An efficient treatment of wastewaters made easy by AERZEN!