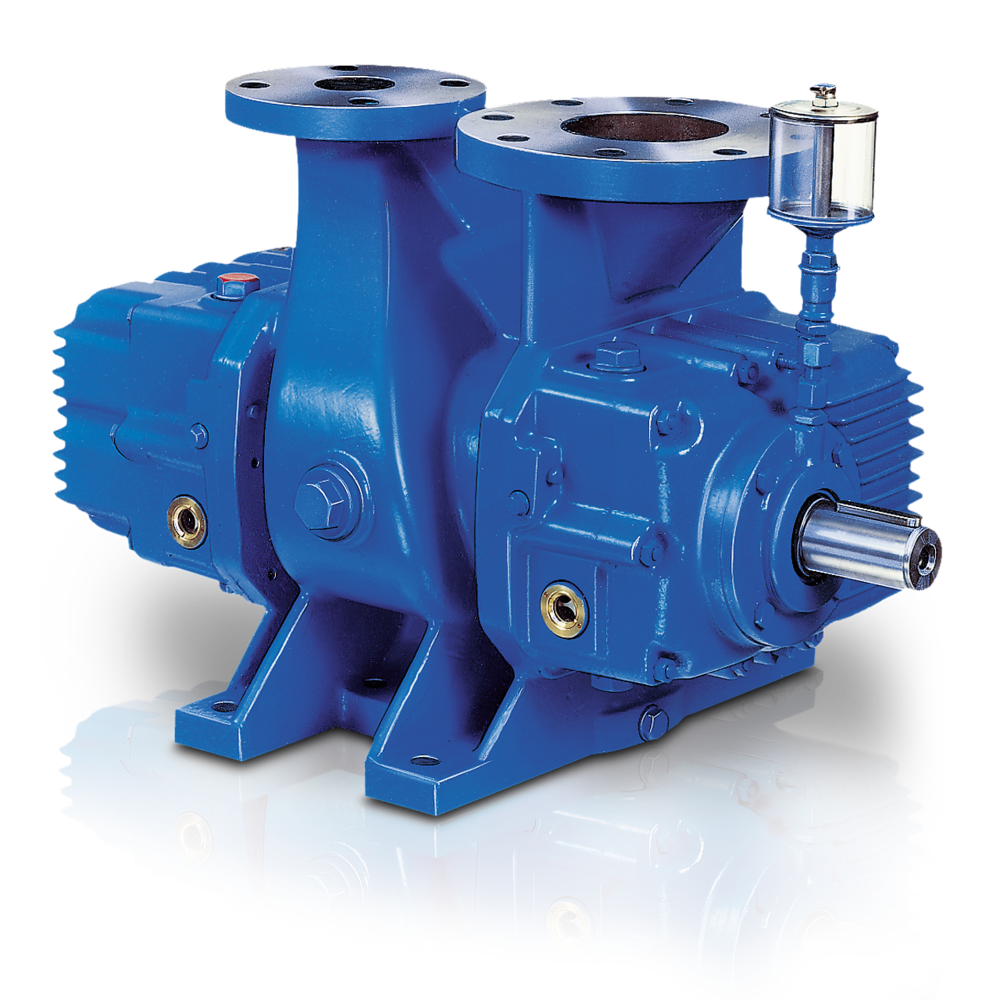

Soffiatori a lobi VUOTO con raffreddamento pre-inlet

I soffiatori AERZEN con motore incapsulato sono progettati per l'aspirazione di gas neutri e aggressivi, e vengono utilizzati in particolare nella tecnologia dell'alto vuoto industriale. La direzione del flusso è verticale dall'alto verso il basso e la trasmissione avviene tramite una cinghia trapezoidale stretta o un accoppiamento diretto.

Portata:

250

-

61,000

m3/h

Vuoto:

10

-

300

mbar

Mezzo aspirato:

Aria,

Gas neutri,

Gas aggressivi

Funzionamento:

oil-free

Vantaggi dei soffiatori per vuoto AERZEN:

- Elevate pressioni differenziali (fino a 800 mbar)

- Elevata riduzione della temperatura di mandata della compressione

- Eccellente varietà di sistemi (la più grande serie al mondo con 11 misure disponibili)

- Per l'installazione e il funzionamento non sono necessari altri regolatori, valvole ecc.

- Ideale per un funzionamento continuo senza problemi di surriscaldamento

Il genio universale per tutte le applicazioni

I soffiatori AERZEN con motore incapsulato sono progettati per l'aspirazione di gas neutri (versione HM) e aggressivi (versione CM), e vengono utilizzati in particolare nella tecnologia dell'alto vuoto industriale. I soffiatori con motore incapsulato operano sempre in combinazione con una pompa ausiliaria*.

La pompa ausiliaria inizia a operare in atmosfera. Il soffiatore con motore incapsulato è generalmente innescato a circa 50-200 mbar e la procedura di pompaggio inizia. A seconda dell'applicazione, come pompe ausiliarie vengono utilizzate pompe ad anello liquido, pompe per vuoto a palette a olio, pompe per vuoto a vite o soffiatori. Se sono provviste di inverter AERZEN e set di parametri speciali, è possibile utilizzare la pompa ausiliaria già a partire dalla pressione atmosferica.

Applicazioni

- Industria dei semiconduttori

- Microelettronica

- Produzione di schermi piatti

- Tecnologia laser

- Tecnologia solare

- Indicatori di perdite di elio

- Tecnologia chimica e di processo

- Rivestimento di vetro e lamine

- Costruzione di forni fusori

- Evacuazione dell'idrogeno

*In caso di utilizzo di un soffiatore per vuoto AERZEN con motore incapsulato, è necessaria una pompa ausiliaria aggiuntiva (sistema multi stadio).

US Units

No- Tecnologia

- Soffiatori a lobi

- Vuoto

- 10 - 300 mbar

- Portata

- 250 - 61,000 m3/h

- Mezzo aspirato

- Aria, Gas neutri, Gas aggressivi

- Funzionamento

- oil-free

Gli esperti del vuoto: soffiatori AERZEN con raffreddamento preingresso

Il corpo è equipaggiato, nel lato aspirazione, con una terza bocca aggiuntiva sul lato aspirazione. La lubrificazione è a sbattimento. La camera di pompaggio è a tenuta di vuoto grazie a un sistema di tenuta. La tenuta sull'albero è garantita da guarnizioni radiali con barriera di grasso. La direzione di flusso è verticale dall'alto verso il basso. La trasmissione può essere ad accoppiamento diretto, oppure, a scelta, con cinghie trapezoidali a sezione stretta (con pressione differenziale limitata).

Vantaggi speciali dei soffiatori AERZEN mHV:

- La serie più grande al mondo con ben 11 misure

- Nel range di basso vuoto, come stadio intermedio nelle pompe multistadio e, in alternativa, utilizzabile anche come depressore contro l'atmosfera

- Adatti per rapporti di compressione alti nel range di basso vuoto fino a p1/p2 = 5

- Adatti al funzionamento continuo senza problemi di surriscaldamento

- Elevata riduzione della temperatura di mandata della compressione

- Niente valvole o regolatori automatici aggiuntivi