Traitement de l'eau et des eaux usées

Solutions efficaces pour les stations d'épuration municipales et industrielles

AERZEN est un leader mondial dans le domaine du traitement des eaux usées. Depuis plus de 150 ans, nous accompagnons les exploitants de stations d'épuration et les partenaires industriels avec des solutions innovantes, affirmant ainsi notre expertise reconnue. Comment économiser de l'énergie et concevoir de nouvelles installations dans le traitement des eaux usées ? AERZEN apporte des solutions polyvalentes et flexibles, fondées sur l’expérience de nombreux projets réalisés.

Demandez-nous, nous sommes heureux de partager notre expérience - PARLONS !

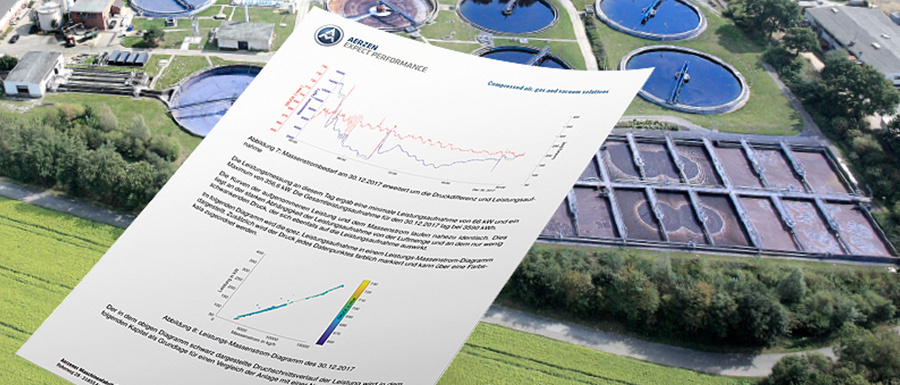

Études de cas

Au fil des plus de 150 ans d'histoire de notre entreprise, nous avons acquis un vaste savoir-faire en tant que fabricant de surpresseurs et de compresseurs. Forte de ce savoir-faire polyvalent, AERZEN est aujourd'hui présent dans plus de 100 000 stations d'épuration dans le monde entier et assure des concepts de solution sur mesure et hautement efficiente pour le marché du traitement des eaux usées. Découvrez-le de vos propres yeux !

Comment économiser de l'argent sur les coûts énergétiques dans le cadre du traitement des eaux usées ? Quelles sont les possibilités de concevoir une nouvelle installation, de remplacer d'anciens modèles et composants ou de moderniser l'installation ? Ce sont des questions importantes pour tout opérateur d'une station d'épuration. AERZEN peut répondre à toutes vos questions grâce à ses solutions polyvalentes et variées.

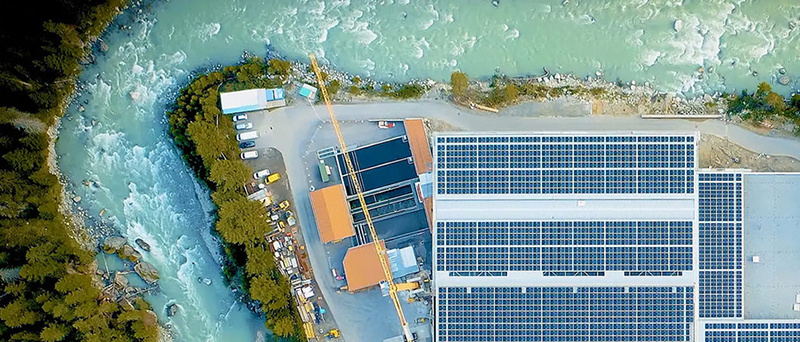

AERZEN est un fournisseur international de premier plan de solutions pour le traitement et la purification des eaux usées. Le traitement des eaux usées dans les stations d'épuration est l'un des domaines les plus importants pour la technologie des soufflantes AERZEN. Les compresseurs, les soufflantes et les turbosoufflantes assurent la ventilation des réservoirs d'aération dans tous les types de stations d'épuration. Les applications vont de la petite station d'épuration biologique aux grandes stations, qui sont responsables du traitement des eaux usées dans plusieurs municipalités. Les machines d'AERZEN enrichissent les eaux usées en fournissant de l'oxygène à l'air comprimé. L'oxygène nécessaire est ensuite transmis aux bactéries, ce qui leur permet de dégrader et d'éliminer les particules de déchets dans le réservoir de ventilation de manière biologique. Cette étape du traitement des eaux usées représente 60 à 80 % des coûts énergétiques totaux de la station d'épuration. Compte tenu de cette part importante des coûts énergétiques, on peut supposer qu'il est possible d'économiser beaucoup d'argent en utilisant la technologie la plus efficace disponible.

En ce qui concerne cette technologie énergétique, une autre étape importante pour une meilleure efficacité consiste à surveiller et à optimiser les fluctuations quotidiennes et annuelles. Un exemple serait les dépenses d'énergie pour l'aération d'un bassin actif de traitement des eaux usées dans un centre de vacances populaire ; un jour d'été chaud avec un volume beaucoup plus élevé, par rapport à un jour froid en hiver. Si les performances des surpresseurs peuvent être réglées et adaptées à ces fluctuations, il est possible d'économiser une quantité considérable d'argent et d'énergie. Pour y parvenir, il convient d'examiner de plus près chaque situation. Quelle est la taille de la station d'épuration, y a-t-il d'importantes fluctuations et/ou la charge de travail est-elle uniformément répartie ? Tous les surpresseurs ont-ils un rendement optimal et correspondent-ils au taux de contrôle et au taux de charge de la station d'épuration ? Quel est l'espace disponible pour la soufflerie ? Combien de temps les installations vont-elles durer et quand devront-elles faire l'objet d'une révision majeure ? En fait, chaque station d'épuration doit établir des plans précis.

Soufflantes volumétriques (soufflantes à piston rotatif)

Les surpresseurs à pistons rotatifs (par exemple le surpresseur Delta d'AERZEN) sont les plus performants des solutions de soufflage. Avec des coûts initiaux relativement bas, ils peuvent couvrir de grandes zones de contrôle et offrent des possibilités d'applications flexibles. Les soufflantes à piston rotatif peuvent facilement s'adapter aux fluctuations de pression et de température.

Les surpresseurs à pistons rotatifs sont de loin les plus utilisés dans le traitement des eaux usées. La flexibilité remarquable de la plage de contrôle peut être facilement réalisée avec un convertisseur de fréquence. Ainsi, l'homogénéité est assurée même en cas de fluctuations de la capacité. Les coûts d'investissement relativement faibles sont amortis en très peu de temps.

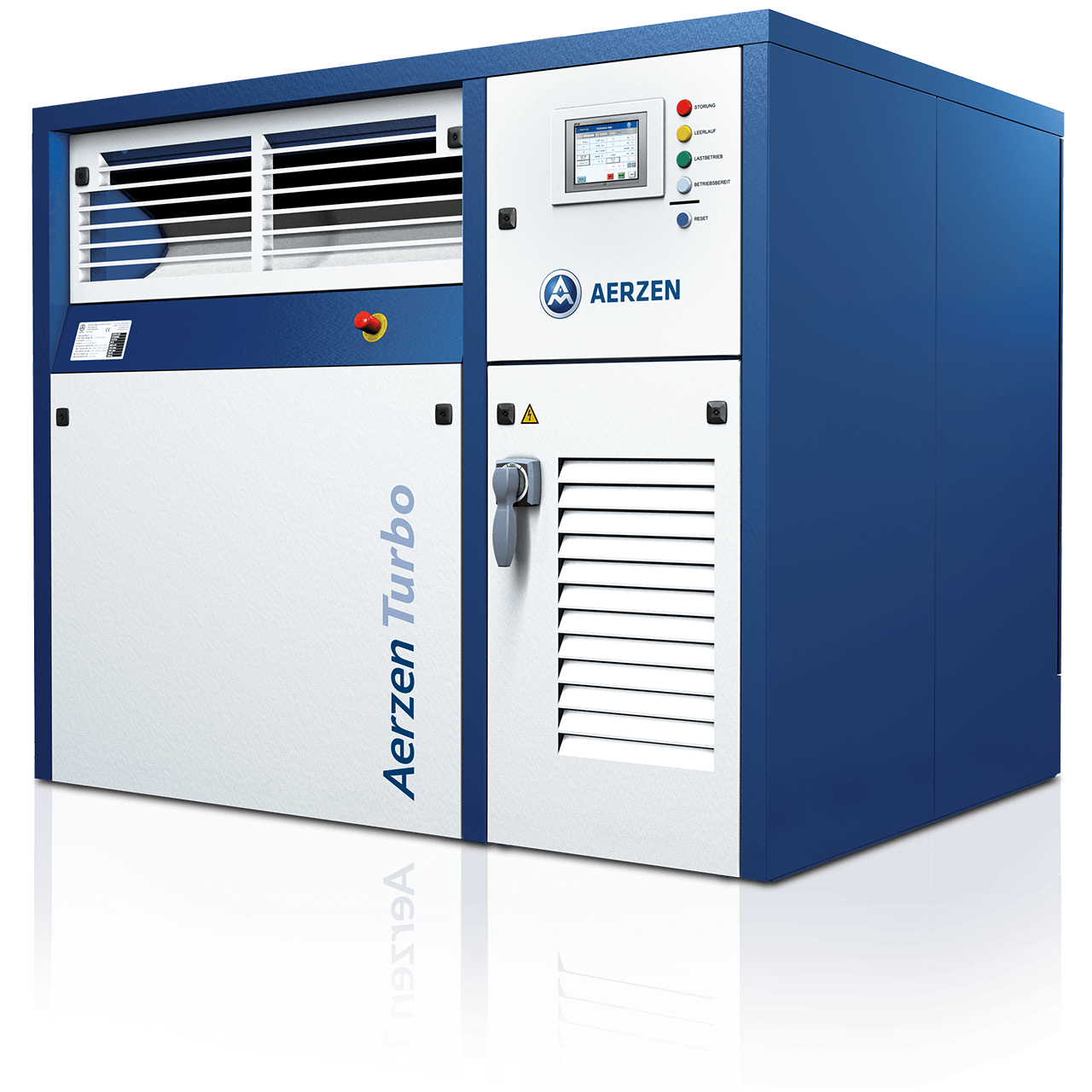

Turbosoufflantes ou turbocompresseurs

La technologie turbo est souvent la solution la plus efficace pour un processus dont la plage de contrôle et la vitesse sont restreintes mais constantes. Avec un fonctionnement continu proche de son point de conception, l'énergie économisée par le turbo est substantielle par rapport aux soufflantes à piston rotatif. Les coûts plus élevés associés à l'achat seront facilement compensés par l'efficacité des turbos. L'utilisation des turbos est moins appropriée dans un système présentant fréquemment des fluctuations extrêmes de pression et de débit.

Un autre avantage du turbo est sa taille réduite. Il nécessite un espace d'installation plus réduit, ce qui permet une utilisation plus souple de l'espace disponible pour la soufflerie (par exemple, pour la modernisation ou la reconception du système). Cela permet également de réduire les coûts. AERZEN fournit le turbo et les autres composants comme un ensemble : le moteur, la soufflerie et le contrôle sont fournis comme une machine complète et une installation simple.

Soufflante hybride (compresseur à pistons rotatifs ou compresseur à lobes rotatifs)

Une soufflante hybride combine les meilleures caractéristiques et avantages des soufflantes rotatives et des compresseurs à vis, avec l'efficacité des turbosoufflantes. La principale différence structurelle réside dans l'utilisation d'un rotor à vis basse pression au lieu d'un rotor à pistons rotatifs droits ou rodés. Ainsi, les fluctuations importantes de débit et de pression peuvent être contrôlées de manière souple et efficace. Les surpresseurs hybrides offrent une plage de régulation similaire à celle des surpresseurs à pistons rotatifs et garantissent un volume relativement constant de variations de pression. Un surpresseur hybride a une plage de régulation de 25 à 100 %. L'avantage par rapport aux turbosoufflantes est l'efficacité supérieure dans les zones de charge partielle de la machine.

L'installation d'une combinaison des technologies de machines susmentionnées est tout à fait intéressante dans les grandes stations d'épuration des eaux usées ou dans les stations de grande capacité et à forte fluctuation (par exemple : un turbocompresseur est utilisé pour la charge de base et une soufflante hybride est activée pour la charge de pointe ou les conditions de faible débit).

Les différents types de machines peuvent être utilisés indifféremment dans les collecteurs de sable et dans le réservoir de ventilation. Une combinaison de turbocompresseurs, de compresseurs à lobes rotatifs et de soufflantes à pistons rotatifs peut améliorer l'efficacité énergétique et réduire considérablement les coûts d'exploitation de la station d'épuration. AERZEN propose des solutions avec son concept "Performance³".

Le premier est le logiciel intelligent AERZEN Performance³ "AERsmart", qui sélectionne la combinaison de machines la plus économe en énergie pour chaque point de fonctionnement requis, garantissant que toutes les machines fonctionneront à leur optimum avec une efficacité maximale.

Les applications dans le domaine de la technologie des eaux usées sont très variées. Pour aider à identifier le système le plus adapté et le plus efficace, AERZEN propose à ses clients une évaluation spéciale, l'"AERaudit", qui permet de mesurer et d'évaluer les données de performance d'un système existant. Sur la base de cette analyse, des améliorations et des possibilités d'économie d'énergie peuvent être déterminées pour l'installation de chaque client. En outre, AERZEN a compilé un assortiment complet de matériel pour la planification des sites pour ses clients. Outre de nombreuses informations sur les produits et la planification, les ingénieurs d'usine, les bureaux d'études et les exploitants de stations d'épuration trouveront également une aide au calcul des données d'exploitation, des informations importantes sur la conception de la salle des machines et des conseils sur les possibilités de récupération de la chaleur lors du traitement des eaux usées.

De nombreux retours d'expérience et rapports d'utilisateurs dans le domaine de l'épuration des eaux usées illustrent, par exemple, comment des solutions efficaces pour des besoins très différents peuvent être créées grâce à l'utilisation appropriée de différents composants de soufflante.

Ainsi, l'efficacité de la station d'épuration de Silverstone au Colorado (États-Unis), construite en 1974 et chargée de l'épuration et du traitement des eaux usées de plusieurs municipalités - y compris des centres de vacances dont la demande fluctue fortement - a été nettement améliorée en remplaçant les anciennes soufflantes centrifuges par la technologie AERZENER Blower et des convertisseurs de fréquence supplémentaires.

Le Turbo TB 100 d'AERZEN (utilisé ici) est équipé d'un moteur à aimant permanent, qui a été spécialement développé pour les exigences de haute fréquence et de grande vitesse d'une application de turbo à entraînement direct. En conséquence, le niveau de bruit a été considérablement réduit et les protections auditives sont devenues inutiles. En outre, l'air chaud provenant du système de refroidissement du ventilateur peut être utilisé en hiver pour la récupération de chaleur, ce qui permet de chauffer le système.

Mais de nombreux exemples de réussite dans les environs témoignent également de la qualité et de la rentabilité des produits AERZEN : Dans la station d'épuration d'Emsbüren, dans le sud de la Basse-Saxe (Allemagne), une turbomachine à palier d'air d'AERZEN a remplacé un turbo à palier magnétique d'un concurrent en mars 2016. Le turbo de la série TB50-0.8 S couvre le fonctionnement à moyenne et haute charge de la station conçue pour 16 000 CEE. Le fonctionnement à faible charge pendant la nuit est couvert par un ventilateur à piston rotatif. Le turbo AERZENER fonctionne par intermittence.

Lors du démarrage, le turbo à palier d'air démarre d'abord en pleine charge et maintient ce fonctionnement pendant 10 minutes. Ensuite, 60 à 70 % du débit volumétrique maximal est réduit pendant une période de 60 à 80 minutes. Une fois que l'oxygène nécessaire a atteint le bassin d'aération, le turbo passe d'abord au ralenti, puis s'éteint complètement. Grâce au fonctionnement intermittent et aux processus d'arrêt appropriés, il a été possible de s'adapter aux différentes exigences de charge et d'économiser de l'énergie. Sur la base d'une bonne relation client avec le turbo à palier d'air d'AERZEN, il était de la responsabilité de l'agence de l'eau de Lingener Land de remplacer une machine à palier magnétique par un turbo à palier d'air d'AERZEN dans la station d'épuration des eaux usées de Spelle.

La station d'épuration de Holzkirchen, près de Munich, est un autre exemple de réussite d'AERZEN en Allemagne. 80 % des coûts énergétiques totaux de l'usine de traitement des eaux usées sont générés ici pour l'entraînement des soufflantes. Par conséquent, une conception sur mesure et l'augmentation de l'impact se sont avérées très rapidement rentables. Pour répondre aux besoins changeants d'air dans le bassin d'aération, un dimensionnement précis de l'air avec une régulation exacte était nécessaire. La commande AERsmart d'AERZEN a trouvé une réponse appropriée. En fonction des besoins en air, elle coordonne différents types de ventilateurs. Comme un pilote automatique, l'AERsmart adopte la gestion du contrôle et de la régulation des unités, avec différents principes de fonctionnement et de mise en œuvre en fonction des besoins. La charge de base est assurée par un turbocompresseur TB75-0.8S. En cas de pics de charge, un compresseur à piston rotatif de la série Delta Hybrid est également utilisé, avec deux soufflantes Delta de l'ancien type, qui assurent l'alimentation en air lorsque la charge est faible. Les charges partielles au sein de l'installation sont largement évitées grâce au contrôle ciblé et à l'utilisation différenciée des différentes machines. Dans le même temps, l'efficacité énergétique augmente. Un traitement efficace des eaux usées facilité par AERZEN !