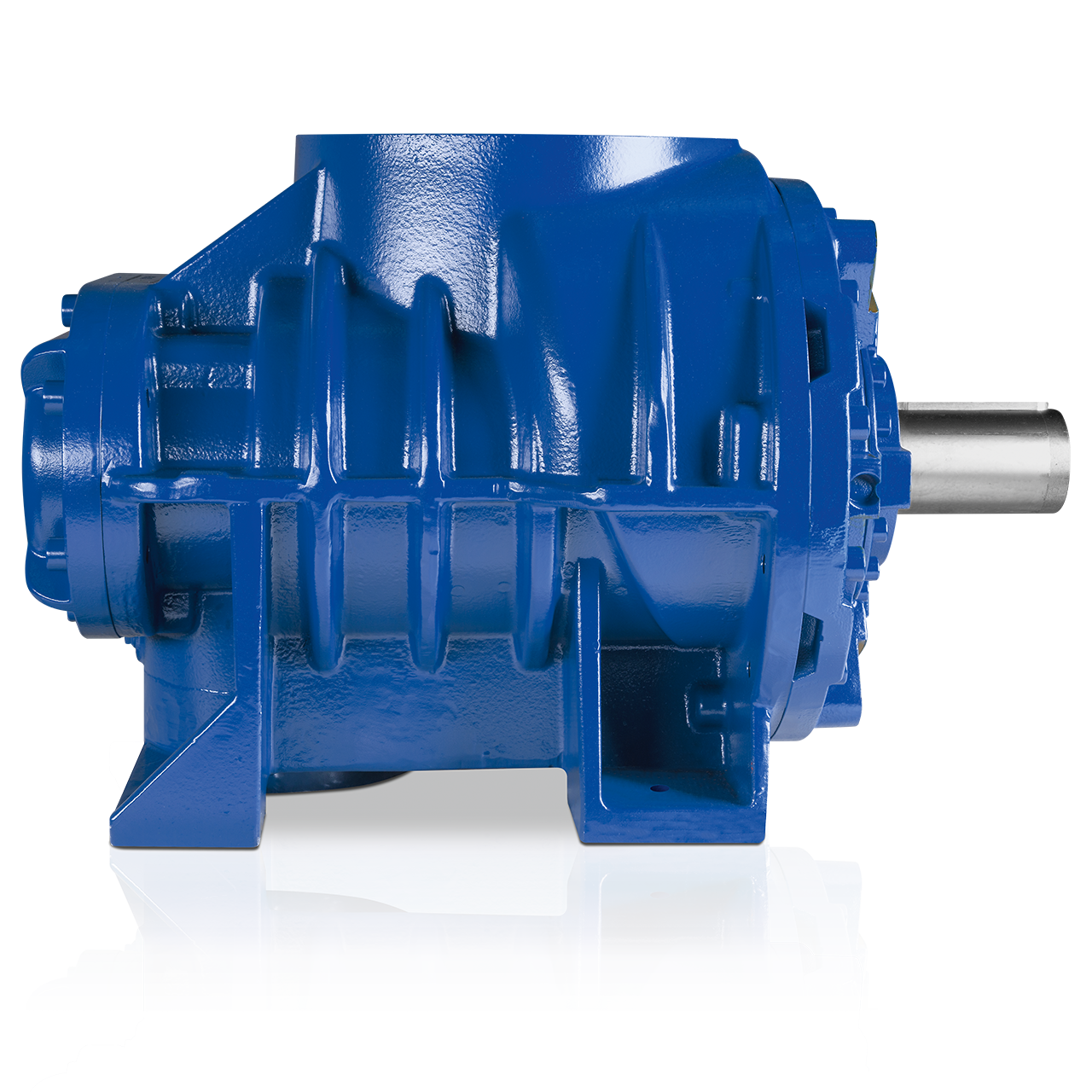

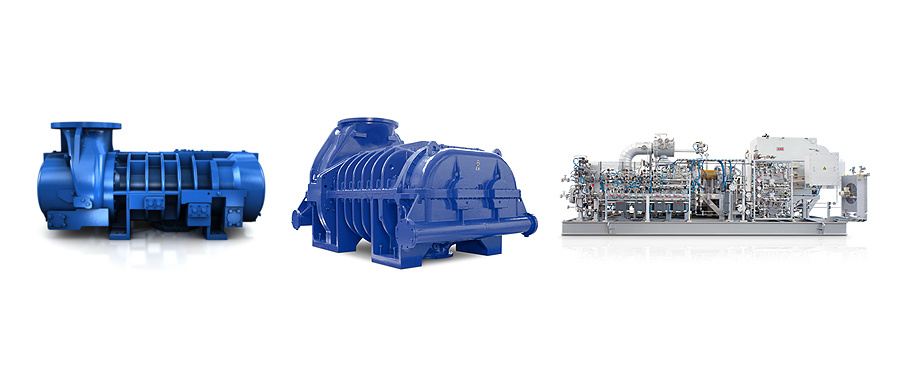

Screw Compressors

The all-round geniuses

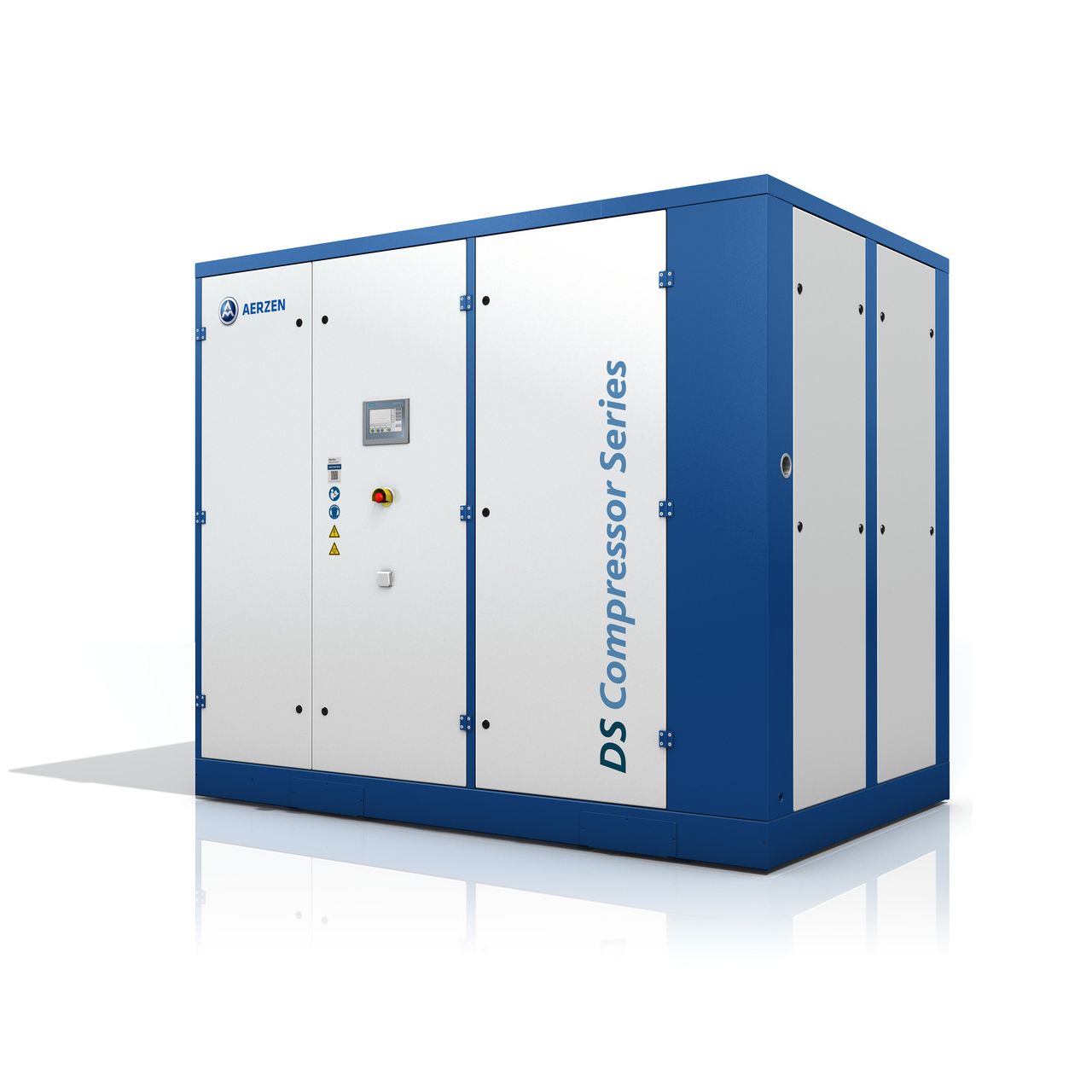

Unrivalled versatility. These two words describe in a nutshell exactly what makes AERZEN screw compressors so special: the biggest range of models, the highest number of possible modifications and the widest range of accessories. But these stages and packaged unit series have a lot more going for them, notably the development capability of the global market leader, who has been continuously working on innovations, optimisation and its completion of its successful compressors since 1943.

Freeing up potential

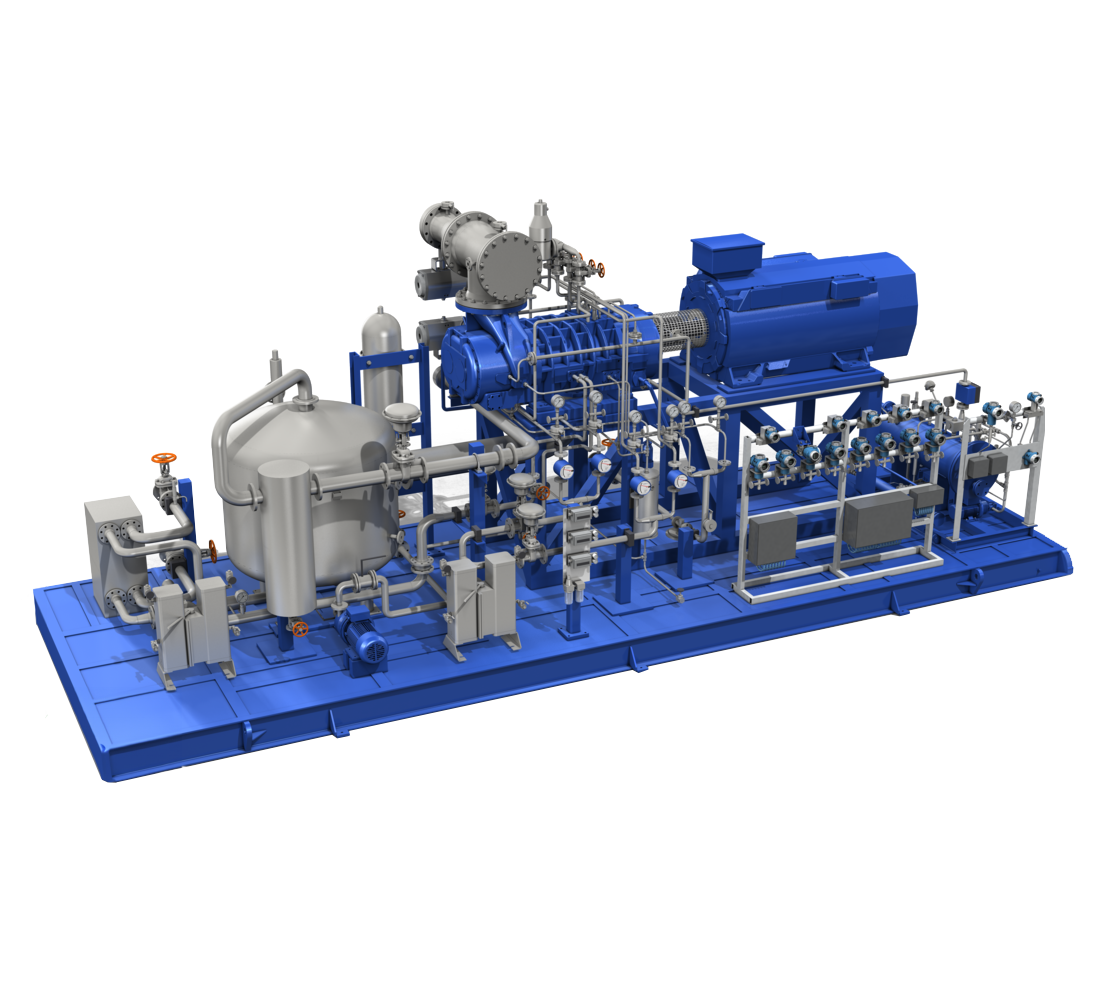

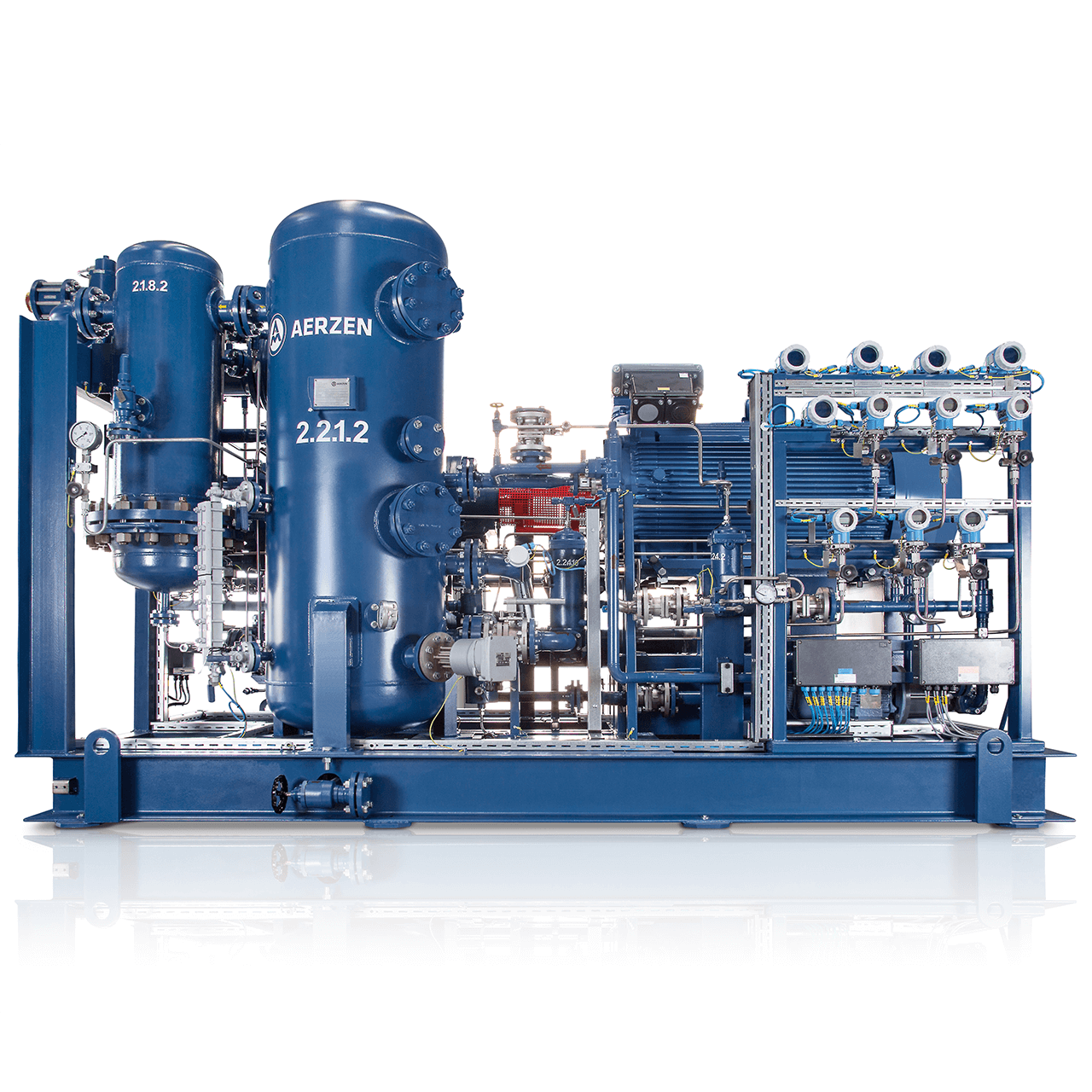

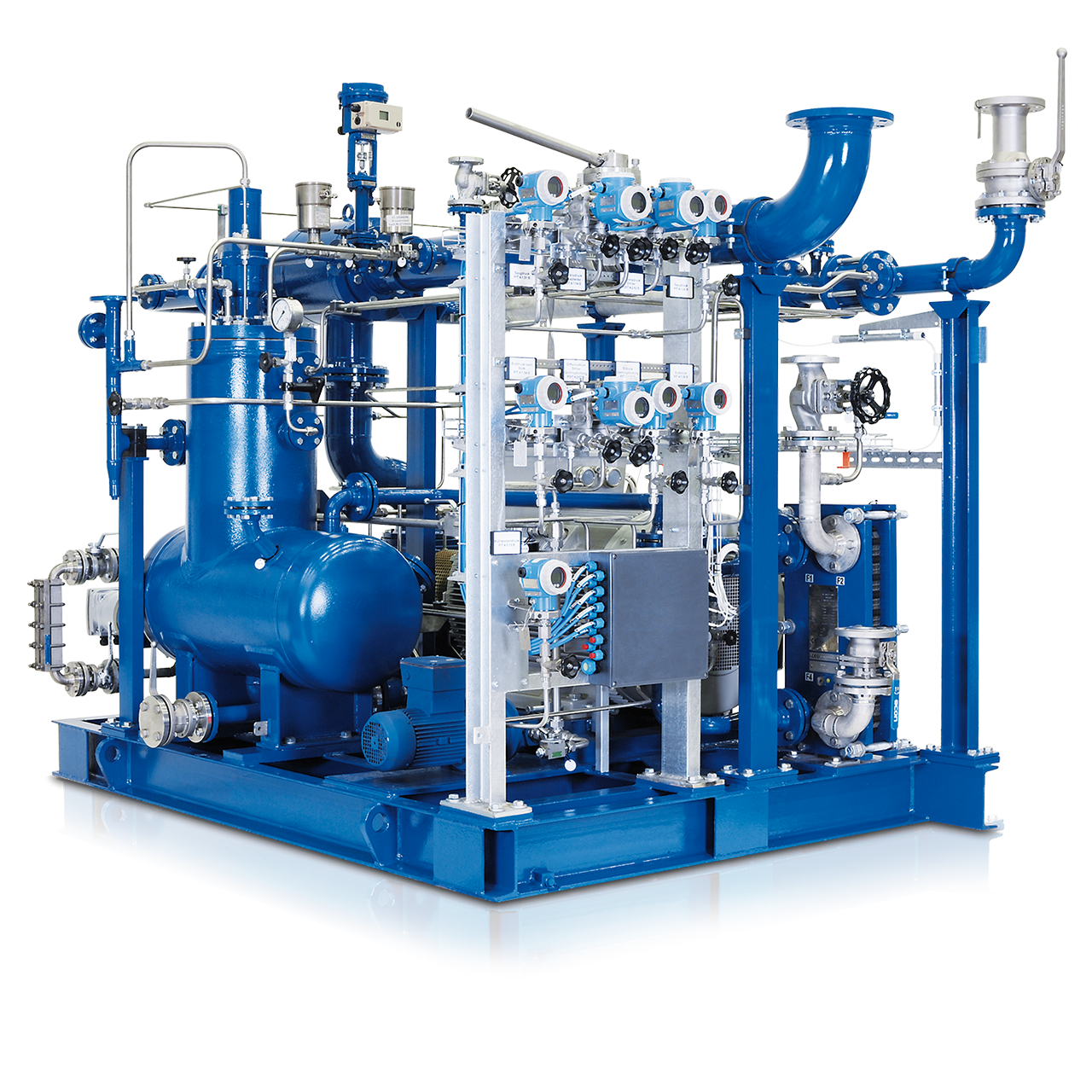

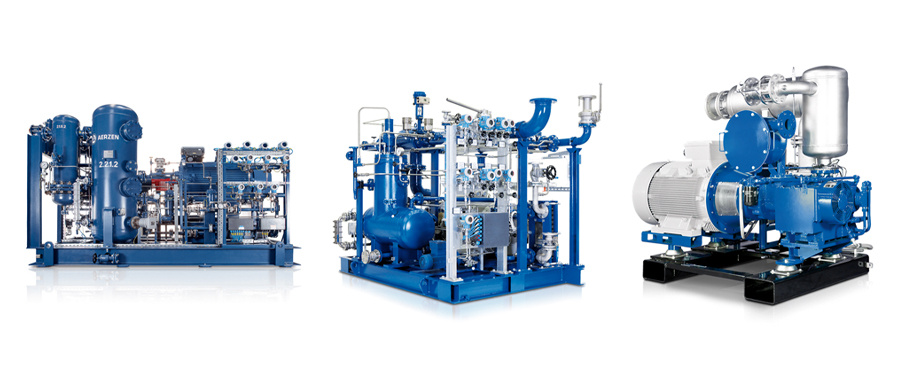

For decades, leading packagers and industrial users have insisted upon AERZEN compressor stages and packaged units. Why? Because with their exceptional versatility these machines are the ideal solution for every application. Originally designed for compressing air, nitrogen and neutral gases, these all-round geniuses are also developing their strengths in use with special gases, in vacuum operation and in inlet pressure applications. Direct and belt-driven, dry running and classified oil-free to class 0 or with oil injection, with or without pre-inlet. Let’s put it this way: AERZEN has the right compressor for every application.

Screw compressors are perforce twin-shaft rotating lobe machines. They work on the positive displacement principle with internal compression and are so-called compulsive conveyors. This applies for all screw compressors. However, what makes AERZEN screw compressors special is that we have made reliability, ease of maintenance, user-friendliness, flexibility and energy efficiency a matter of principle. The result is a range of unique design features. Take the efficiency coefficients for example, such as the AERZEN 3+4 VML profile or the 4+6 VM profile. Compared to standard compressors they save a considerable amount of energy. And what is the ultimate in compressor technology? It is AERZEN's new E-compressors. With an increase in efficiency of around 6% they free up even more valuable potential.

Oil-free screw compressors for the highest application standards

In compression processes in industry, as well as medical and food technology, it is often necessary to compress air in such a way that absolutely no foreign residues remain in the compressed air. Oil-free screw compressors are the ideal choice for this, as no foreign material is introduced into the compressed air. Many conventional piston compressors and rotary compressors work with oil, due to better heat dissipation. Moreover, depending on the construction principle applied, the oil serves as a seal for spaces. However, for applications where hygiene is critical, compression should be oil-free, and adding a compressed air filter should also be considered.. This ensures that no greasy residue will end up in the feed air. Such systems are also termed oil-free. Rotary compressors are basically displacement machines that are operated with two screw-shaped rotors and that compress air using internal compression. This concept is not new, but in terms of energy efficiency, reliability and ease of maintenance, AERZEN’s machines are in a class of their own.

Energy efficiency is becoming increasingly important for screw compressors

Screw compressors are designed as rotary compressors. These compress gas via the rotation of the meshing rotors that are arranged in a screw shape. Thus, the compression space is gradually reduced and the volume of gas compressed. The reliable production of compressed air is necessary both in industry and in power plants, as well as many other sectors. Conventional compressors produce a great deal more noise than screw compressors, due to their different operational principles. Moreover, the wear and tear in screw compressors is generally lower. The result is robust, reliable and maintenance-friendly machines for many applications. A distinction is also made between machines that are direct drive and those that are belt-driven. Questions of economy prompt many trade companies to switch to screw compressors. The efficiency during compression is especially high, which has a positive impact on energy consumption. In an age of high energy prices, this is a very important aspect, while the issue of heat recovery also plays a role.

Screw compressors are multi-facetted

Screw compressors are extremely low-maintenance, because there are fewer moving parts. Due to the absence of oscillating forces, the compressor stages are less prone to cracking and other wear. Screw compressors also boast advantages with respect to the efficiency of compression, because piston compressors lose approximately a tenth of the suctioned air via the piston rings. A screw compressor experiences significantly less pressure loss and rarely exceeds a value of 0.1 – 0.2 percent. With respect to basic construction, screw compressors can be considered superior to piston compressors, and are much more efficient. They allow a large reduction in energy costs and CO2 emissions during use. There is further optimisation potential in the flow of the compressed air during the screw compression process. When needed, premium motors with the highest energy efficiency are available in order to meet the requirements of the current efficiency class. Future reliability is especially important for customers in this context, because longevity is partly determined by whether or not the future demands made on the efficiency class can be met.

Fewer vibrations mean less noise

There are one- and two-lobe rotary compressors,but when speaking of screw compressors, what is usually meant are two rotors arranged in parallel, with different screw profiles. These mesh like gears and compress the gas that is trapped between. When these are not oil-free machines, oil will be injected to cool and seal. This procedure, called fluid cooling, is recommended when the operating conditions require higher surrounding temperatures. Oil can also assist in minimising wear and tear because contact is prevented. Oil-free premium constructions manage without this measure and, thanks to high-precision production methods and synchronised sprockets, are low-friction and absolutely tight. A huge advantage of screw compressors is how quiet they are while in use. Unlike piston compressors, no masses have to be stopped at their respective dead centre. The vibrations inside a rotary compressor are significantly reduced.

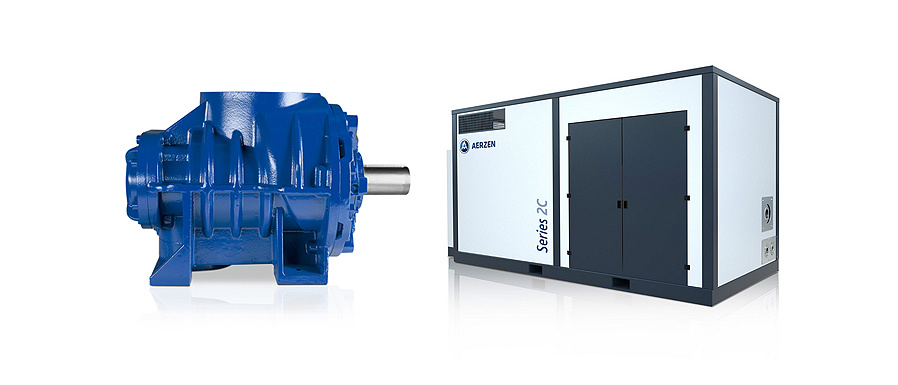

Perfect sound insulation by optimizing flow control

The energy efficiency of screw compressors can be optimised through various measures. Improvements in the flow of air into the compressor unit have been proven to be especially effective. In machines in the latest 5 plus generation from AERZEN, all of the components are precisely aligned to provide optimal flow. Reducing pressure losses and improving the intake and outlet openings help ensure the stable and reliable provision of the desired discharge pressure. The additional sound insulation not only reduces the noise level during use but also optimises the flow conditions. By using an innovative insulation geometry, the sound pressure levels sink. Moreover, it acts as an effective spark arrester. Machines fitted with this feature are also approved for explosion-protected plant areas. In spite of the optimal insulation features, no additional material is needed for this insulation. There is no need to worry about contamination from damaged insulation material, etc. The corresponding maintenance work is also eliminated. In addition to the need for oil-free compressors, effective insulation without the danger of any sort of contamination is one of the most important requirements in areas of the food industry where hygiene is critical and in chemical plants. When needed, a compressed air filter can also be utilised to clean the used air. In medical fields, special filters like these to prepare the compressed air are common, as is a separation system for other residues. To avoid any unwanted moisture in the area of application, boosters and dryers ensure the effective removal of any signs of moisture present in the air. It is guaranteed that no grease will end up in the chamber at any time – which qualifies the new models as completely oil-free compressors.

Easy operation and flexible retrofitting possibilities

The convenient operation of modern rotary compressors is not a problem in today’s digital age. Operation and maintenance are easy and reduce further costs. The smooth belt drive of the machines in the 5 plus generation makes it possible to install various belt pulleys to achieve the desired ratio. Making changes isn’t a problem, either. The compressor remains flexible in the event of changes to the desired parameters and does not have to be replaced by a different model with inflexible settings. Maintenance is extremely low for the belt drive, because the correct tension is guaranteed via its own weight. The speed of many of the devices can also be electronically controlled. High precision and exact adherence to the desired pressure are an absolute must in most applications. An integrated control panel can be found directly on the housing. Through placement of the control panels on the front of the devices, units can be arranged side by side to save space. A possible oil check during operation is also possible. Special AERZEN oils increase the changing interval to twice that of prescribed values.

Quality is the most important criterion

The high quality of AERZEN’s premium compressors is internationally recognised. Low operating costs and high value retention go hand in hand with excellent reliability and durability to ensure that the use of modern rotary compressors meets the highest economic and environmental criteria.