Surpresseurs à lobes

Éprouvés, testés – plus innovants que jamais

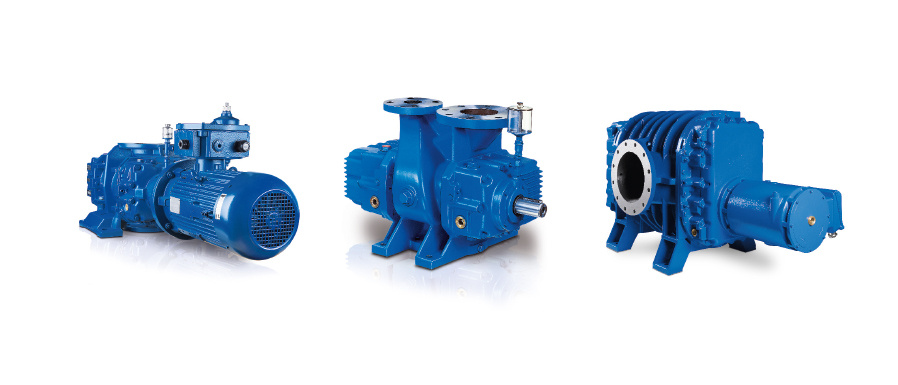

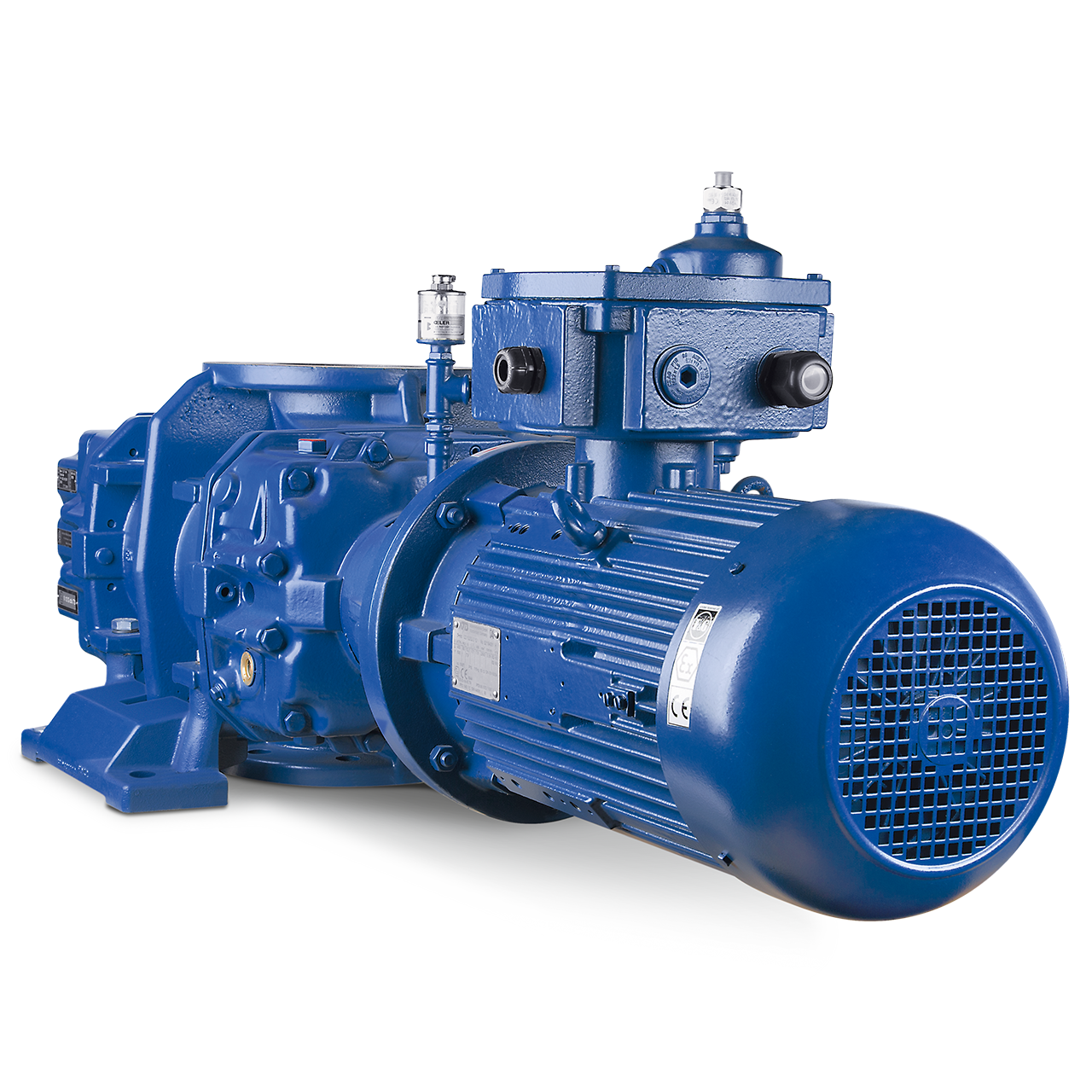

AERZEN a fabriqué le premier surpresseur à lobes d’Europe. C’était en 1868. Aujourd’hui, ces étages et groupes font partie des meilleurs compresseurs de tous les temps. Nous fabriquons des produits standard très perfectionnés pour de nombreuses applications. Ils sont utilisés dans tous les secteurs de l’industrie. Nos machines sont hautement perfectionnées, économiques et extrêmement durables. La conception Roots a ouvert la voie du développement des surpresseurs à lobes, et c’est une bonne chose. Encore aujourd’hui, 150 ans plus tard, c’est toujours une de nos conceptions les plus réussies. Aujourd’hui, les surpresseurs à lobes à deux arbres d’AERZEN pour le transport de gaz exempt d’huile sont plus innovants que jamais. Les nombreuses évolutions de la fabrication garantissent un haut rendement énergétique.

La technologie brevetée d’AERZEN, par exemple la réduction des pulsations intégrée, garantit des émissions et des vibrations sonores faibles. La facilité de réparation et la réduction à long terme des frais de cycle de vie sont aussi des caractéristiques des surpresseurs d’AERZEN. Et la liste des innovations ne s’arrête pas là. Mais qu'est-ce qui est le plus important en termes d’usage au quotidien ? La durabilité de nos surpresseurs. C’est ce qui fait la réputation d’AERZEN.

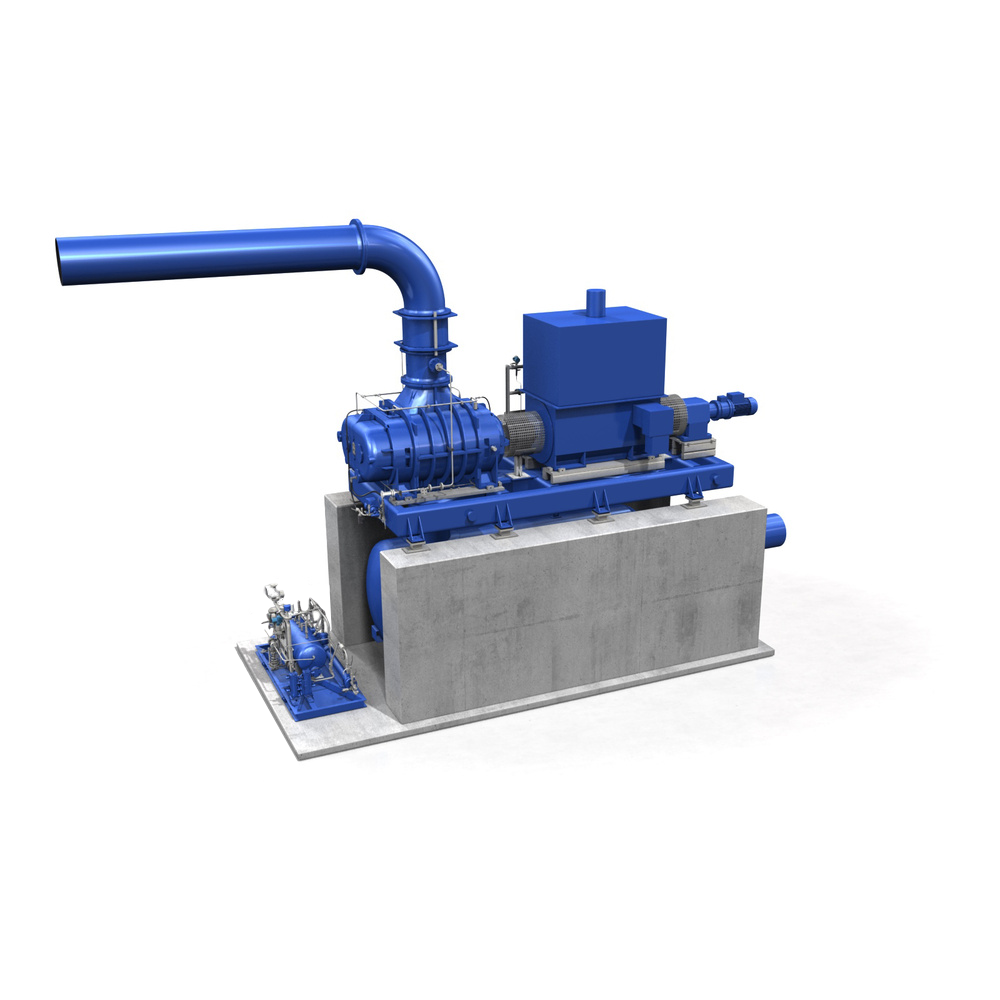

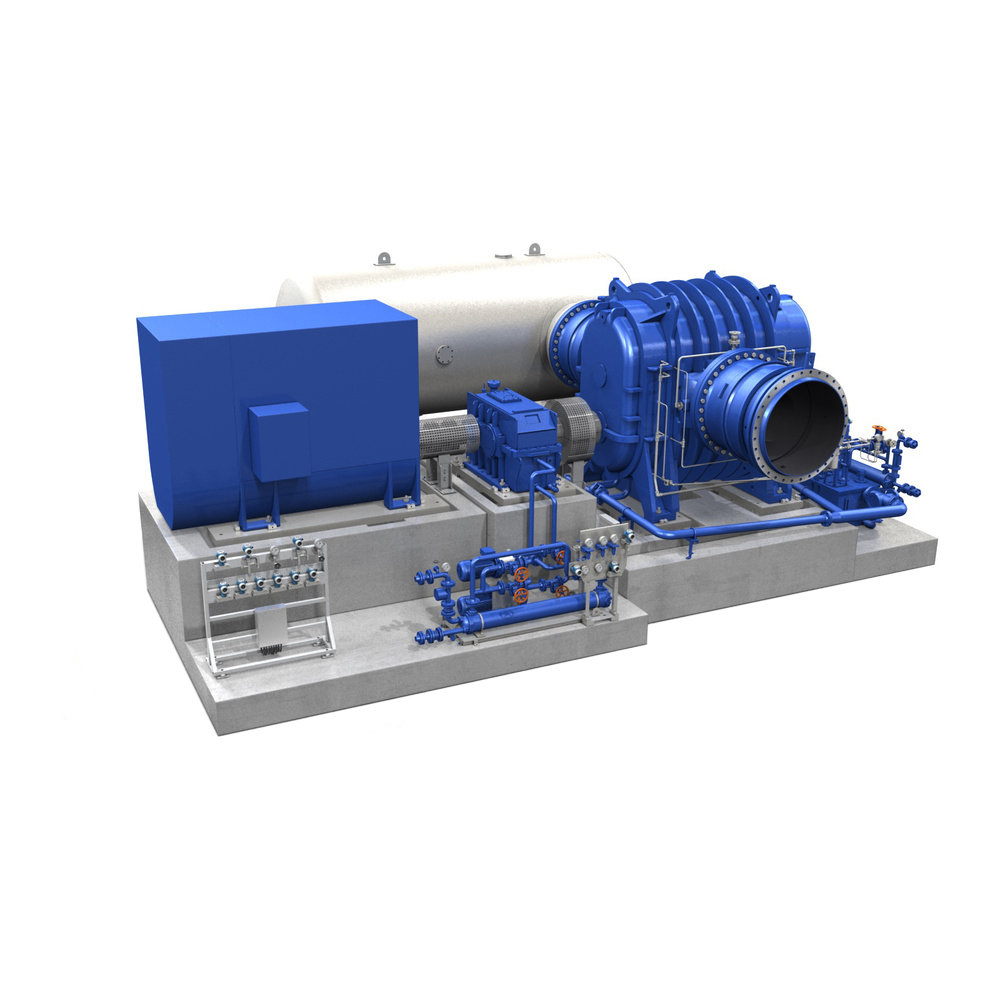

Les compresseurs et les soufflantes de l'entreprise sont utilisés dans un large éventail d'industries. Le principal domaine d'application des soufflantes et des compresseurs est le traitement de l'eau et des eaux usées. Les compresseurs et les soufflantes sont utilisés pour aérer les bassins d'aération dans les stations d'épuration, soit individuellement, soit en tant que groupe de machines. Par nature, ce processus est très économe en énergie et donc en coûts. En tant que spécialiste des applications, AERZEN a développé des solutions très efficaces et économes en ressources dans ce domaine, à l'aide de systèmes de contrôle intelligents, d'une combinaison de différentes technologies de compresseurs d'air et de possibilités de récupération de la chaleur.

Les soufflantes sont également utilisées dans les domaines du transport pneumatique, de la chimie et du génie des procédés, de la technologie de la pression et du vide, ainsi que dans l'industrie des gaz de process et de la réfrigération. En raison de la diversité des tailles, des types de construction et des équipements spéciaux, les surpresseurs à pistons rotatifs peuvent être mis en œuvre de manière extrêmement flexible. Les machines peuvent être montées verticalement ou horizontalement. La flexibilité est également de mise en ce qui concerne les fluides transportés : la gamme d'applications s'étend de l'air et de l'oxygène aux gaz inertes, corrosifs ou toxiques.

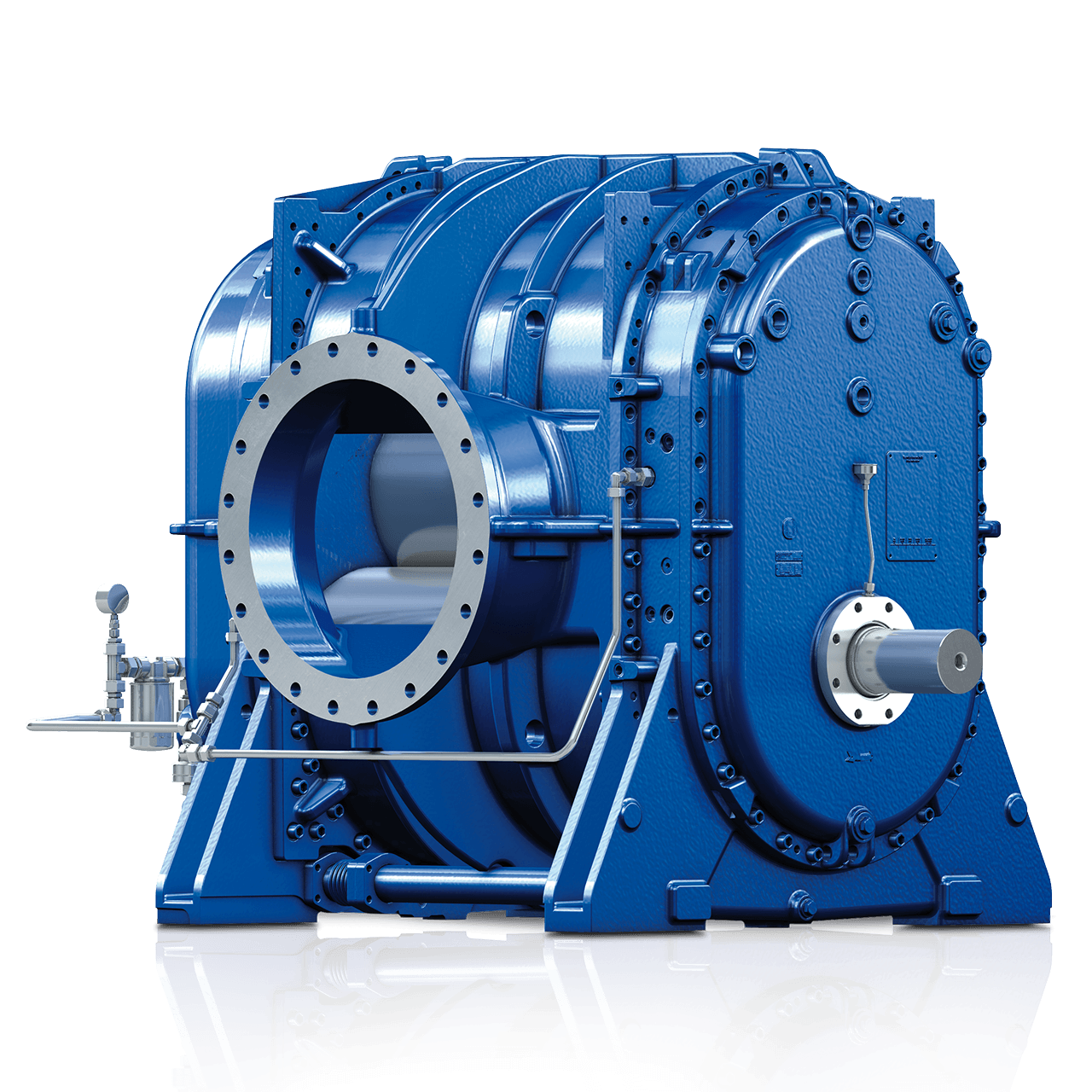

L'ingénierie des soufflantes est basée sur le principe de Roots. Le terme "Roots" remonte aux inventeurs américains Philander et Francis Roots, qui ont fait breveter la soufflerie Roots en 1860. La technologie Roots implique des pistons rotatifs à trois lobes qui tournent dans un boîtier cylindrique, transportant ainsi le fluide gazeux du côté de l'aspiration au côté du refoulement. La compression du fluide est créée par le reflux des gaz accélérés du côté du refoulement. Cela génère une pression différentielle pouvant aller jusqu'à 1000 mbar.

Les surpresseurs à pistons rotatifs de la société sont efficaces, durables et robustes et sont utilisés dans le monde entier. La fiabilité proverbiale de ces machines s'explique : AERZEN fabrique tous les composants clés en interne, de l'assemblage au système de contrôle, et, ce faisant, l'entreprise familiale accorde de l'importance à la qualité et à la durabilité. Seuls des matériaux de haute qualité sont utilisés pour la production. Le développement, la production, la vente, l'assemblage et l'entretien des produits de l'entreprise, ainsi que le système de gestion de la qualité, ont été certifiés à plusieurs reprises.

Le nom Génération 5 fait référence aux nombreuses innovations techniques que ce produit incarne. L'une d'entre elles est la gamme des grands volumes. La soufflante avancée pour le traitement de l'air et des gaz inertes génère un volume de 30 à 15 000 m3/h. Le surpresseur volumétrique est disponible dans toutes les tailles standard et peut être modifié en fonction des spécifications du client, ce qui permet une mise en œuvre flexible. En outre, la série se caractérise par une grande efficacité, de faibles coûts de maintenance, des coûts de cycle de vie réduits, une compacité et une simplicité de manipulation.

De l'air de traitement pur à 100

Un autre argument de vente est la production de gaz de traitement sans huile certifié par le TÜV. Cette caractéristique joue un rôle majeur dans des secteurs industriels tels que l'agroalimentaire, où les surpresseurs sont utilisés par exemple pour le transport pneumatique ou l'aération de produits en vrac tels que la farine ou d'autres aliments pulvérulents.

Silencieux sans matériau absorbant

Dans ce secteur, les machines de la Génération 5 Delta Blower présentent une autre caractéristique importante : elles offrent une protection acoustique innovante grâce à des silencieux réactifs. Les silencieux conventionnels sont équipés d'un revêtement insonorisant qui, avec le temps, se fatigue et s'use sous l'effet de l'énergie des ondes sonores. Cette usure expose l'air du processus à un risque d'encrassement par le matériau absorbant. Le silencieux réactif innovant d'AERZEN est dépourvu d'absorbants et n'atténue le son qu'en détournant l'air - cette caractéristique rend ce type de machine particulièrement adapté à l'utilisation dans l'industrie alimentaire et chimique. La technologie brevetée de protection acoustique présente également d'autres avantages : la pureté du fluide empêche l'encrassement de la machine. Les pertes de pression qui surviennent dans toutes les applications d'air comprimé restent constantes pendant toute la durée de vie de la machine. Cela évite une augmentation des pertes de pression par des dépôts dans la machine, et réduit les coûts de nettoyage et d'entretien.

Les supports de base des soufflantes sont également certifiés comme pare-étincelles pour les applications ATEX.

Plus silencieux grâce à la réduction intégrée des pulsations

Une innovation spécialement développée pour la soufflerie Delta est représentée par le processus breveté de réduction des pulsations, qui est intégré dans la marche elle-même. Deux canaux coulés dans le cylindre permettent de contrôler l'inversion du fluide dans la chambre de transport de manière à éviter les pulsations de retour et d'écrasement. Cela permet déjà de réduire le bruit dans la marche de la soufflerie et d'augmenter la durée de vie des roulements. Cette technologie est intégrée dans toutes les tailles de soufflantes Delta.

Conception intelligente - manipulation aisée

La dernière génération de surpresseurs à pistons rotatifs se distingue également par sa conception générale : ils sont compacts et ne nécessitent qu'un petit espace de montage. Cela permet de construire des salles des machines de dimensions plus réduites. La conception compacte permet le transport à l'aide d'un chariot élévateur ou d'une plate-forme élévatrice. Les supports de machine flexibles isolent les bruits d'impact, contribuant ainsi à un fonctionnement plus silencieux. La conception permet également un accès convivial à l'avant. Par exemple, le niveau d'huile peut être lu de l'extérieur lorsque la machine est en marche, et les pièces d'usure telles que le filtre à huile peuvent être vérifiées simplement et rapidement.

La conception extrêmement robuste permet d'utiliser le surpresseur pour un fonctionnement continu, même dans des conditions environnementales difficiles. Les surpresseurs à pistons rotatifs de type Delta Blower peuvent être utilisés sous tous les climats - avec les modifications nécessaires, même dans les zones sismiques - ou être installés sur des navires ou pour d'autres applications mobiles.

AERZEN fabrique des produits standard de haute qualité, mais offre également une large gamme de modifications spécifiques aux clients. Selon les souhaits du client, il est possible d'utiliser des moteurs spéciaux, des revêtements spéciaux ou des versions ATEX. Si l'assemblage doit être installé dans le désert, il peut être spécialement équipé d'un collecteur de sable. Des capots acoustiques robustes spéciaux sont disponibles pour les charges de vent accrues dans les régions sujettes aux tremblements de terre ou aux ouragans. Si nécessaire, les composants peuvent être fabriqués dans des matériaux de construction spéciaux pour l'application de gaz spéciaux. Une documentation étendue spécifique au client est également possible.

L'entreprise est un acteur mondial et offre un excellent service : Avec plus de 45 filiales et agents nationaux et plus de 2 000 employés, elle est présente dans le monde entier. Le service que l'entreprise fournit à ses clients dans le monde entier est également présent et proche. Le réseau de vente et d'entreprise très proche garantit une disponibilité fiable des machines et des services AERZEN - une assistance locale est possible tout au long du cycle de vie d'une installation. L'entreprise offre à ses clients une gamme étendue de services qui va au-delà des pièces de rechange et des réparations. Outre la mise en service professionnelle de nouvelles installations, AERZEN propose également des sessions de formation sur site, la surveillance et l'inspection des machines. Des contrats de service et de maintenance individuels sont également disponibles, ainsi que des solutions plug & play attrayantes, qui sont fournies sous la forme de machines entièrement configurées, paramétrées et prêtes à être installées, avec un ensemble de services intégrés.

![[Translate to French:] Canned motor blowers [Translate to French:] Canned motor blowers GM8000](/fileadmin/user_upload/01_images/01-05_subpages/01-05-01_products/positive_displacement_blowers/vacuum_pumps/canned_motor_blowers/GM_8000_1.png)

![[Translate to French:] AERZEN Vacuum Vacuum with pre-inlet cooling MHV](/fileadmin/user_upload/01_images/01-05_subpages/01-05-01_products/positive_displacement_blowers/vacuum_pumps/vacuum_with_pre-inlet_cooling/Blower-Vakuum-mit-Voreinlass-MHV.png)