Compresseurs à vis

Du pur génie.

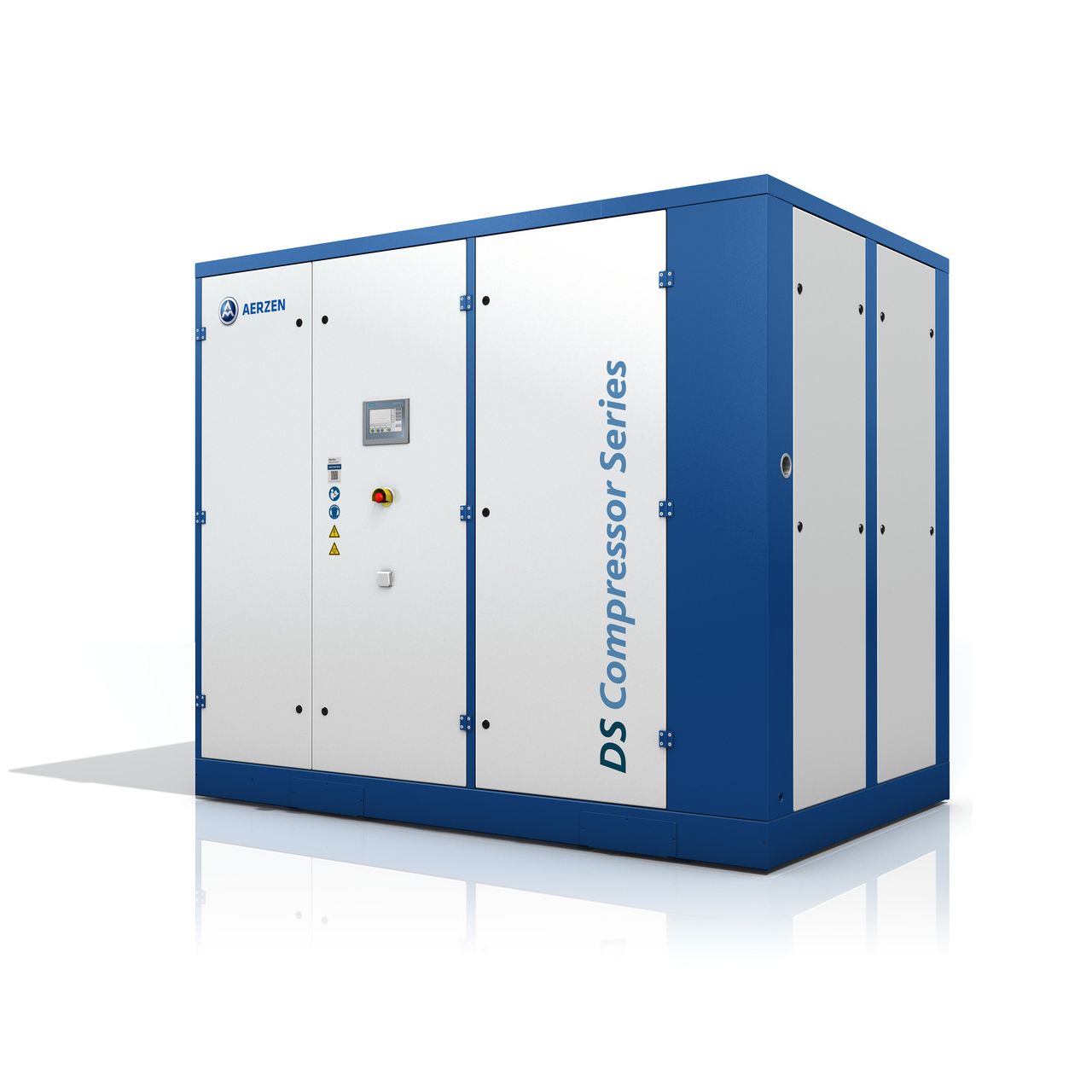

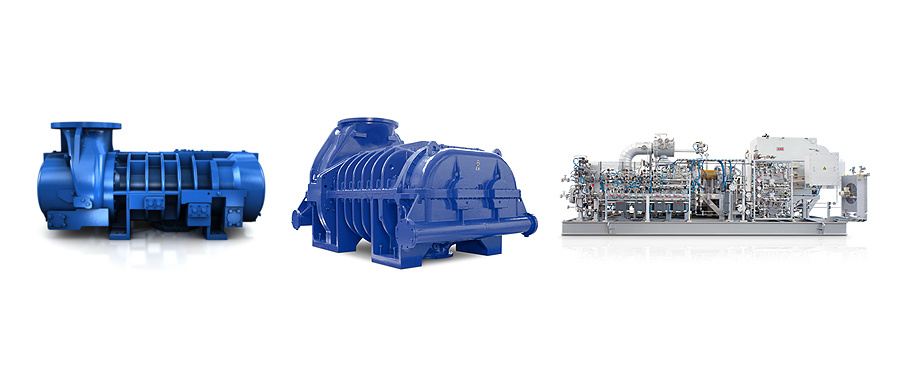

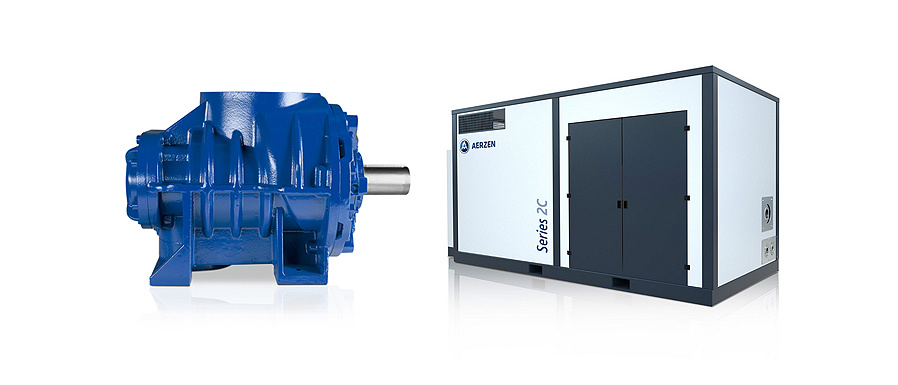

Une polyvalence sans pareille : Ces deux termes décrivent exactement ce qui rend les compresseurs à vis d’AERZEN si spéciaux : le plus large éventail de modèles, le plus grand nombre de modifications possibles et la plus large gamme d’accessoires. Mais ces étages et groupes, sont beaucoup plus avantageux, et cela sans parler de la capacité de développement du leader sur le marché mondial, qui a travaillé de façon continue sur l’innovation, l’optimisation et la perfection de ses fameux compresseurs depuis 1943.

Libérer le potentiel

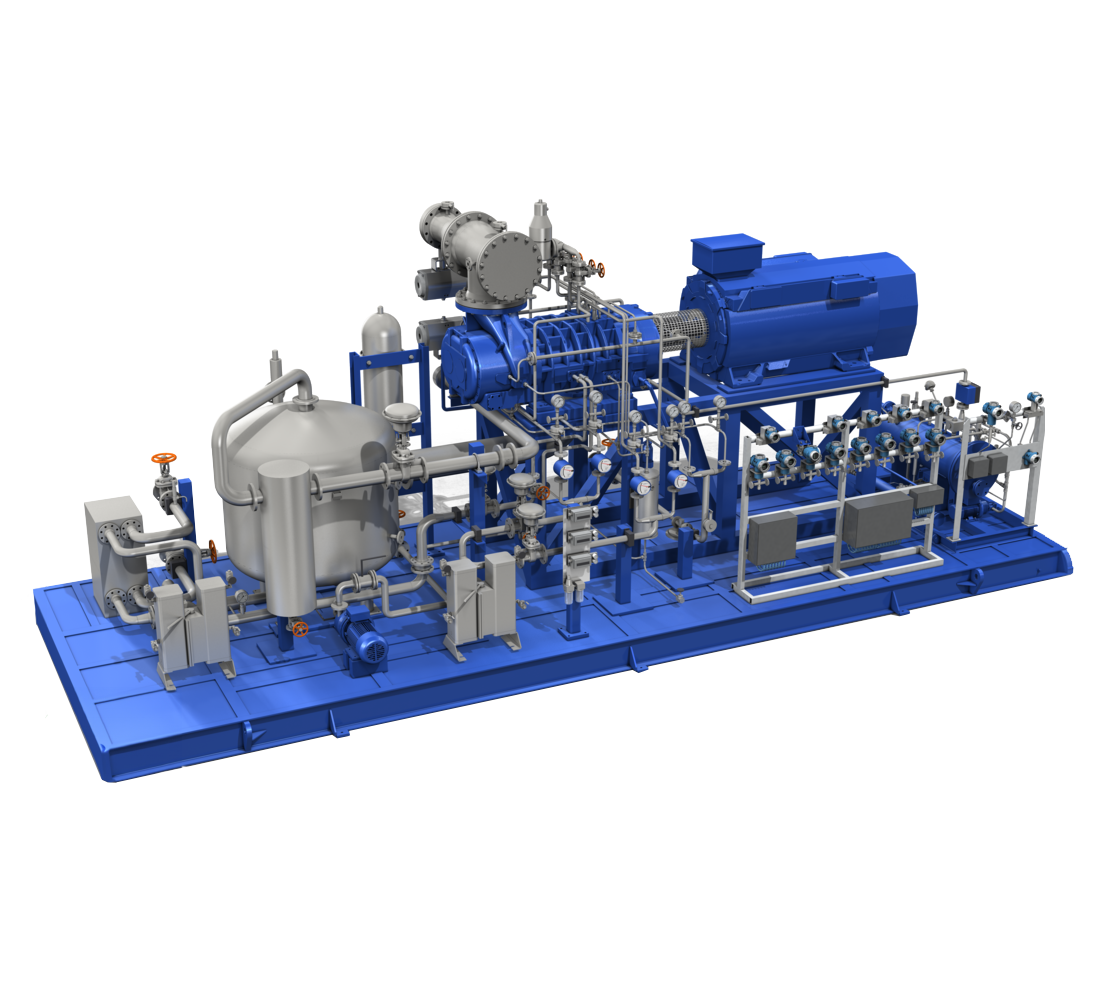

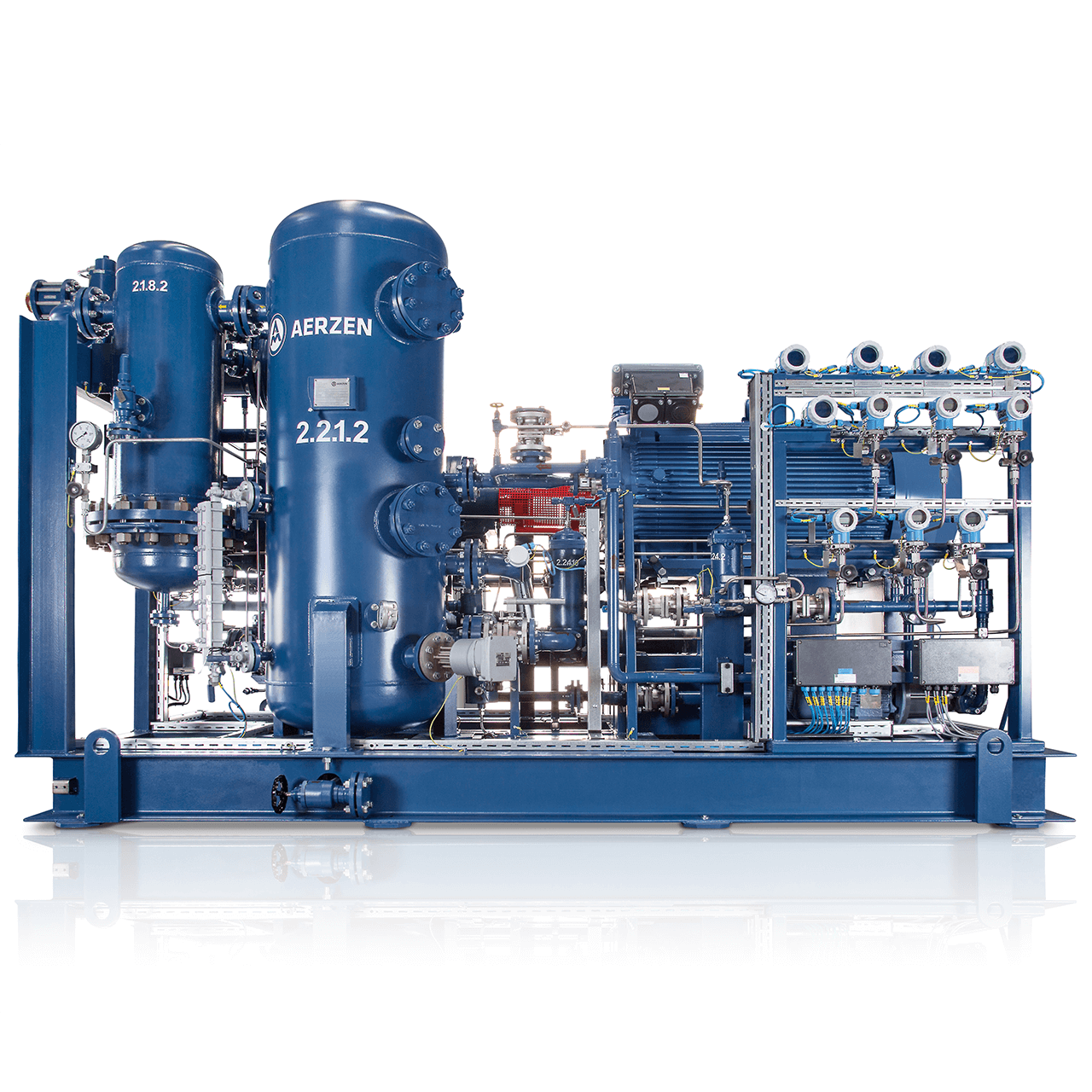

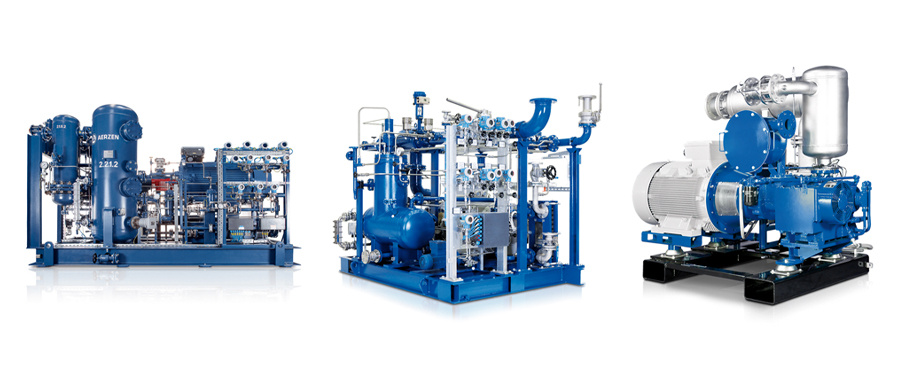

Depuis des décennies, les principaux emballeurs et utilisateurs industriels ont insisté sur les étages de compresseur et les unités emballées d'AERZEN. Pourquoi ? Parce qu'avec leur polyvalence exceptionnelle, ces machines sont la solution idéale pour chaque application. Conçus à l'origine pour comprimer l'air, l'azote et les gaz neutres, ces génies polyvalents développent également leurs points forts dans l'utilisation de gaz spéciaux, dans le fonctionnement sous vide et dans les applications de pression d'entrée. Entraînement direct ou par courroie, fonctionnement à sec, sans huile jusqu'à la classe 0 ou avec injection d'huile, avec ou sans préadmission. En d'autres termes, AERZEN a le bon compresseur : AERZEN a le bon compresseur pour chaque application.

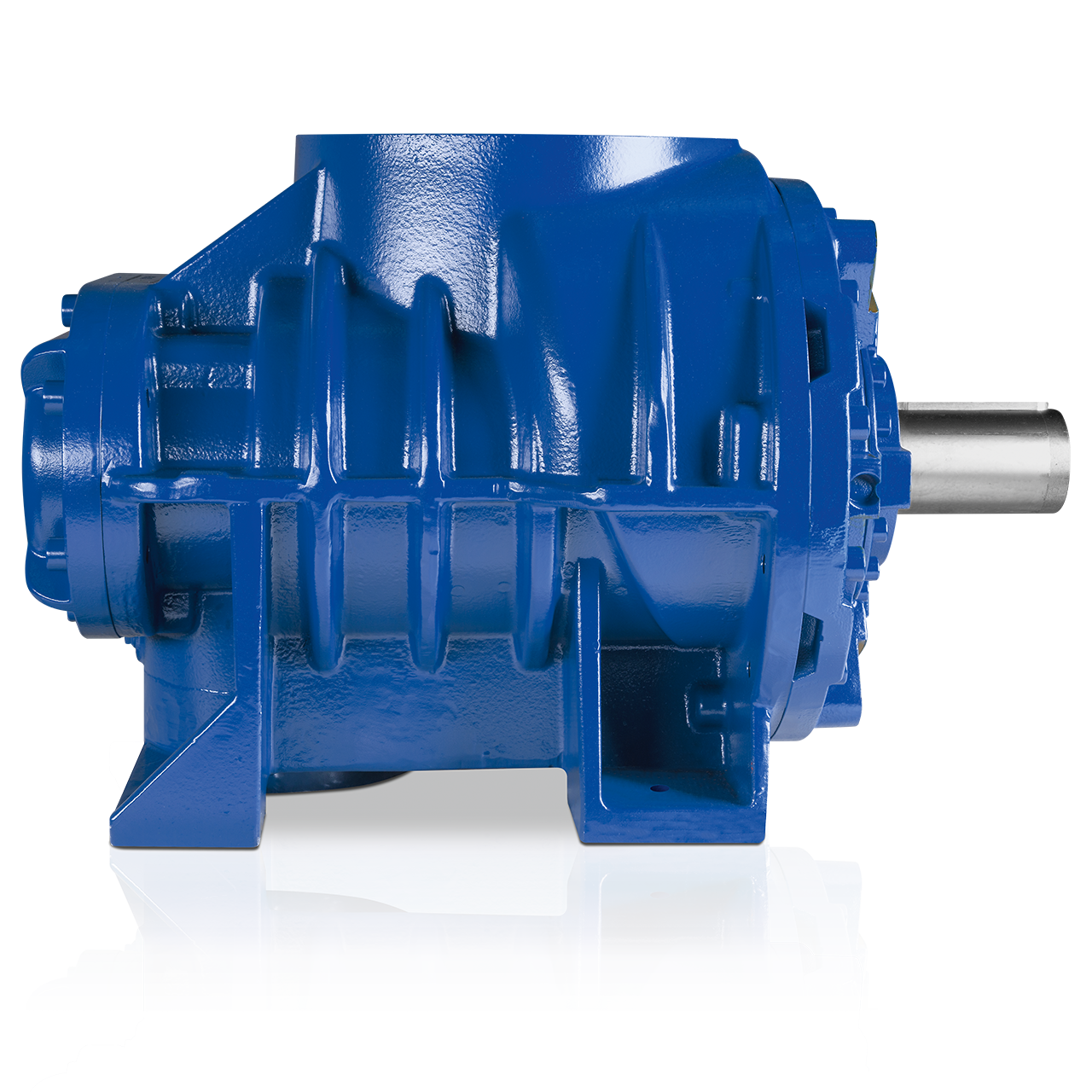

Lescompresseurs à vis sont des machines équipées d’un lobe rotatif et d’arbre double. Ils fonctionnent selon le principe de déplacement positif avec compression interne et sont appelés des convoyeurs compulsifs. Cela s’applique à tous les compresseurs à vis. Cependant, ce qui rend les compresseurs à vis d’AERZEN spéciaux c’est que, chez nous, la fiabilité, la facilité de maintenance, la convivialité, la flexibilité et l’efficacité énergétique occupent une place centrale. Le résultat est une gamme unique de caractéristiques de conception. Par exemple, les coefficients de rendement, comme le profil VML 3+4 ou le profil VM 4+6 AERZEN. Ils permettent des économies d’énergie considérables par rapport aux compresseurs standard. La technologie de pointe en matière de compresseurs : Il s'agit des nouveaux E-Compresseurs d'AERZEN. Avec une augmentation de l’efficacité d’environ 6 %, ils libèrent encore plus de potentiel intéressant.

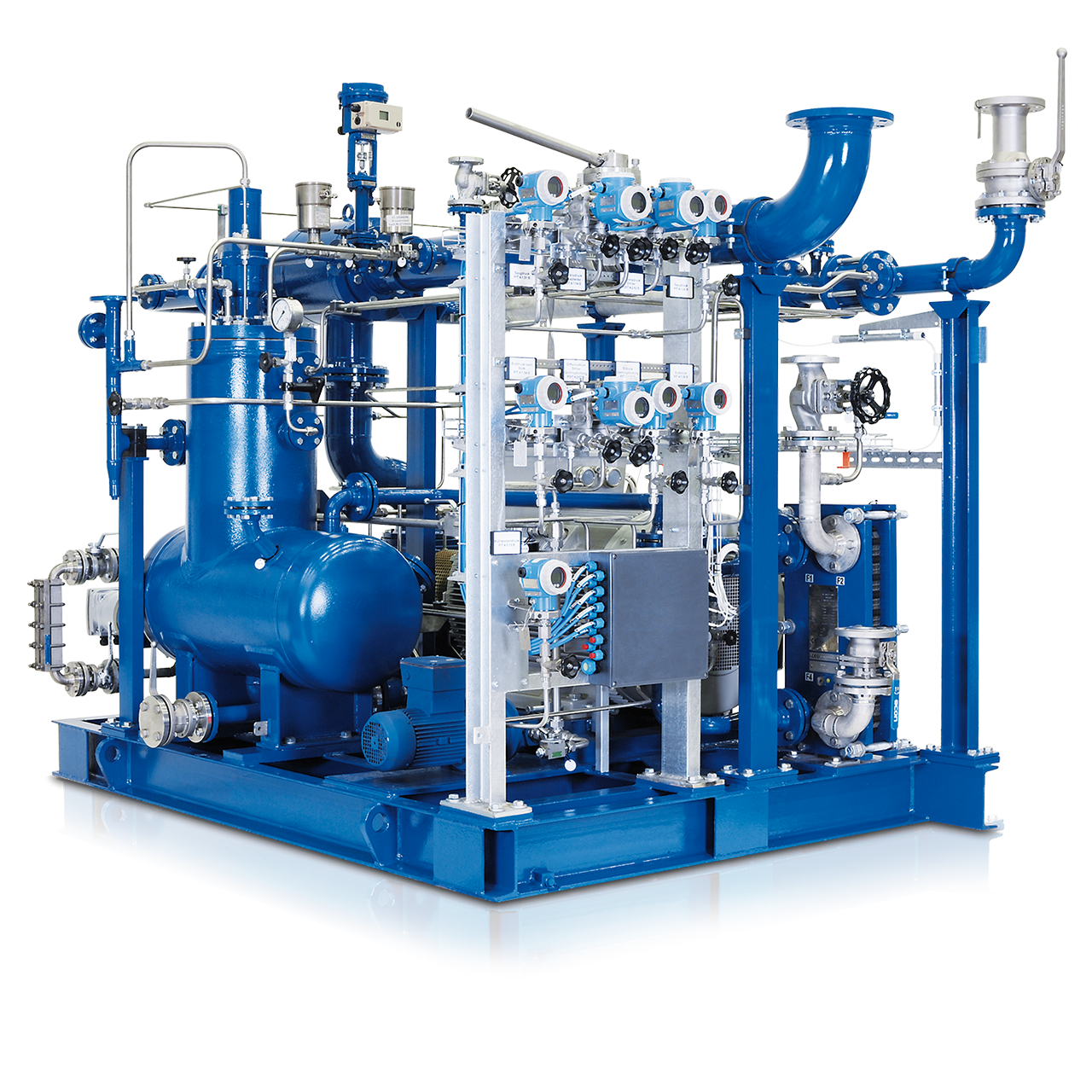

Compresseurs à vis non lubrifiées pour les applications les plus complexes

Dans les processus de compression dans l'industrie, ainsi que dans les technologies médicales et alimentaires, il est souvent nécessaire de comprimer l'air de manière à ce qu'aucun résidu étranger ne subsiste dans l'air comprimé. Les compresseurs à vis non lubrifiées constituent le choix idéal car aucun corps étranger n'est introduit dans l'air comprimé. De nombreux compresseurs à piston et compresseurs rotatifs conventionnels fonctionnent avec de l'huile pour une meilleure dissipation de la chaleur. En outre, selon le principe de construction appliqué, l'huile sert de joint d'étanchéité pour les espaces. Toutefois, pour les applications où l'hygiène est essentielle, la compression doit se faire sans huile et l'ajout d'un filtre à air comprimé doit également être envisagé. Cela garantit qu'aucun résidu graisseux ne se retrouve dans l'air d'alimentation. Ces systèmes sont également dits « exempts d'huile ». Les compresseurs rotatifs sont essentiellement des machines volumétriques qui fonctionnent avec deux rotors en forme de vis et compriment l'air par compression interne. Ce concept n'est pas nouveau, mais en termes d'efficacité énergétique, de fiabilité et de facilité de maintenance, les machines d'AERZEN sont dans une classe à part.

L’efficacité énergétique devient de plus en plus importante pour les compresseurs à vis.

Les compresseurs à vis sont conçus comme des compresseurs rotatifs. Ils compriment le gaz par la rotation des rotors qui sont disposés en maillage sous forme de vis. Ainsi, l'espace de compression est progressivement réduit et le volume de gaz, comprimé. La production fiable d'air comprimé est nécessaire tant dans l'industrie que dans les centrales électriques, ainsi que dans de nombreux autres secteurs. Les compresseurs conventionnels génèrent beaucoup plus de bruit que les compresseurs à vis en raison de leurs principes de fonctionnement différents. En outre, l'usure des compresseurs à vis est généralement plus faible. Il en résulte des machines robustes, fiables et faciles à entretenir pour de nombreuses applications. On opère également une distinction entre les machines à entraînement direct et celles à entraînement par courroie. Les questions d'économie incitent de nombreuses entreprises commerciales à passer aux compresseurs à vis. L'efficacité de la compression est particulièrement élevée, ce qui a un impact positif sur la consommation d'énergie. À une époque où les prix de l'énergie sont élevés, il s'agit d'un aspect très important, tandis que la question de la récupération de la chaleur joue également un rôle.Les compresseurs à vis ont de multiples facettes

Les compresseurs à vis ne nécessitent que très peu de maintenance car ils contiennent moins de pièces mobiles. En raison de l'absence de forces oscillantes, les étages compresseurs sont moins sujets aux fissures et autres formes d'usure. Les compresseurs à vis présentent également des avantages en ce qui concerne l'efficacité de la compression car les compresseurs à piston perdent environ un dixième de l'air aspiré par l'intermédiaire des segments de piston. La perte de charge est largement inférieure dans les compresseurs à vis : elle dépasse rarement 0,1 à 0,2 %. En ce qui concerne la construction de base, les compresseurs à vis peuvent être considérés comme supérieurs aux compresseurs à piston et sont beaucoup plus efficaces. Ils permettent de réduire considérablement les coûts énergétiques et les émissions de CO<sub>2</sub> pendant l'utilisation. Le débit de l’air sous pression peut encore être optimisé durant le fonctionnement du compresseur à vis. Si nécessaire, nous mettons à votre disposition des moteurs premium dont l’efficacité énergétique est maximale afin de répondre aux exigences des classes de rendement actuelles. La fiabilité à long terme est particulièrement importante pour les clients dans ce contexte car la longévité est en partie déterminée par le fait que les exigences futures imposées à la classe d'efficacité peuvent être satisfaites ou non.

Moins de vibrations, moins de bruit

Il existe des compresseurs rotatifs à un ou deux lobes, mais lorsque l'on parle de compresseurs à vis, il s'agit généralement de deux rotors disposés en parallèle, avec des profils de vis différents. Ceux-ci s'imbriquent comme des engrenages et compriment le gaz qui est piégé entre les deux. Si vous n’utilisez pas un équipement exempt d’huile, de l’huile sera injectée pour le refroidissement et les joints. Cette procédure est appelée refroidissement par fluide : elle est recommandée lorsque les conditions de fonctionnement nécessitent des températures ambiantes plus élevées. L'huile peut également contribuer à minimiser l'usure car elle permet d'éviter le contact. La construction premium exempte d’huile y arrive sans avoir d'huile dans la chambre de compression, tout en étant complètement scellée grâce aux méthodes de production très précises et aux pignons de synchronisation à faible friction. Les compresseurs à vis ont l’avantage d’être particulièrement silencieux lorsqu’ils sont utilisés. Contrairement aux compresseurs à piston, aucune masse ne doit être arrêtée à son point mort. Les vibrations à l'intérieur d'un compresseur rotatif sont significativement réduites.

Isolation sonore parfaite, en optimisant le flux d'air

Il y a différentes façons d’optimiser l’efficacité énergétique des compresseurs à vis. L'amélioration du flux d'air dans le compresseur s'est avérée particulièrement efficace. Dans les machines de la dernière Génération 5 plus d'AERZEN, tous les composants sont alignés avec précision pour assurer un débit optimal. La réduction des pertes de charge et l'amélioration des entrées et des évacuations contribuent à assurer la fourniture stable et fiable de la pression de refoulement souhaitée. L’isolant supplémentaire réduit le niveau sonore durant le fonctionnement, tout en optimisant le débit total. La géométrie de l'isolant innovant permet de réduire le niveau sonore. Elle sert en outre de barrière pare-étincelles. Les machines équipées de ce dispositif sont également approuvées pour les zones d'usines protégées contre les explosions. Grâce à cet isolant optimal, aucun matériau supplémentaire n’est nécessaire. Inutile de vous soucier de la contamination liée notamment à un matériau isolant endommagé. Vous pouvez également oublier les frais de maintenance. Outre la nécessité d'avoir des compresseurs exempts d'huile, une isolation efficace sans risque de contamination est l'une des exigences les plus importantes dans les secteurs de l'industrie alimentaire où l'hygiène est cruciale et dans les usines chimiques. Si nécessaire, un filtre à air comprimé peut être utilisé pour nettoyer l’air utilisé. Dans le domaine médical, il est courant d'utiliser de tels filtres destinés à préparer l’air comprimé, ainsi qu'un système de séparation pour les autres résidus. Pour éviter leur présence indésirable dans la zone d’application, toutes les moisissures de l’air peuvent être éliminées efficacement par des boosters et des sécheurs. Nous vous garantissons qu’il n’y aura jamais de graisse dans la chambre de compression — les nouveaux modèles de compresseurs sont donc complètement exempts d’huile.