First use of AERZEN screw blowers for the pneumatic transport of fish feed in marine aquacultureRevolution in salmon farming

The world loves fish. Around 20 kg are consumed per capita per year on average – and the appetite is growing. To meet the growing demand, the fish industry is increasingly turning to aquaculture. More than half of the world's edible fish already comes from controlled farms. For certain fish species, including salmon, this proportion is even higher. Chile is one of the most important countries of origin for farmed salmon. The South American country is the second largest producer and exporter after Norway. The waters and fjords south of the port city of Puerto Montt, also known as the “Gateway to Patagonia”, are considered the epicentre of Chilean salmon farming.

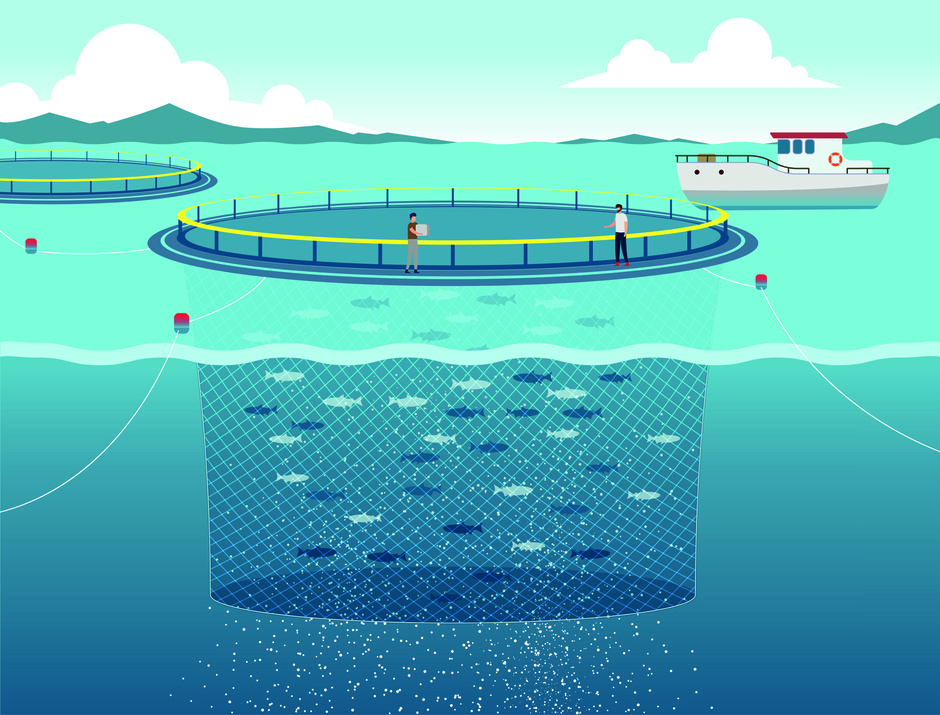

Pneumatic transport of fish feed in salmon farming

One of the salmon farms has six complete feeding lines for two separate modules with a total of 14 net cages. Around 980,000 salmon are supplied here. This is done using special feeding vessels equipped with automated systems for storing, dosing and pneumatic conveying of the feed to the fish. Since summer 2025, six AERZEN screw blowers from the Delta Hybrid D13S have been in use. They transport the feed from the storage silos to the net cages and ensure efficient, reliable and economical operation.

The 60-day test phase was a complete success

Screw blowers for pneumatic conveying of fish feed in marine aquacultures? This has never happened before. Conventional lobe blowers are usually used for this application – and that was also the case here. However, a 60-day test phase with the AERZEN Delta Hybrid exceeded all expectations and delivered such excellent results that the changeover to the new technology was quickly decided. The high energy efficiency, the lower operating costs,

the smaller motor size and the constant reliability of the screw blowers were particularly convincing. The decision in favour of the six Delta Hybrid not only reflects the technical excellence of the AERZEN machines, but also the high level of satisfaction with the support and service. The AERZEN team worked closely and promptly throughout the process, demonstrating technical expertise and a depth of understanding of the application's specific challenges.

Special requirements on blower technology

Offshore applications such as marine aquaculture pose special challenges. They are far away from electricity sources and have to be powered by diesel generators, which results in a high CO2 carbon footprint. The feeding vessels are constantly moving and have limited space. The environment is also salty, corrosive and humid. No problem for the screw blowers and rotary lobe compressors from AERZEN. The innovative packages combine the advantages of blower and compressor technology in a single system and have long been considered the ultimate in pneumatic conveying of sensitive, powdery and granular media – regardless of the conditions.

AERZEN Delta Hybrid: energy-saving champion with impressive qualities

AERZEN Delta Hybrid stand for maximal energy efficiency, minimum life cycle costs, absolute process reliability as well as high durability and represent 100% oil-free, absorbent-free and PFAS-free process air (oil-free operation according to ISO 8573-1, class 0). The robust and service-friendly design (including a patented storage with a service life of up to 70,000 operating hours) ensures a high level of machine availability. The comprehensive range of options and integrated modifications allows targeted customisation to individual customer process requirements and ensures the greatest possible flexibility in the design of machines and systems.

Efficient operation, small motor sizes, digital remote monitoring

Six AERZEN Delta Hybrid of size D13S are in operation on the fish farm in Patagonia. These compact packages each have a drive power of 16.68 kW and deliver a volume flow of 10 m³/min at a differential pressure of 770 mbar. The discharge temperature is 52.7°C – which is 15°C lower than with conventional positive displacement blowers. This has a positive effect on the quality of the fish feed and the conveying process. Due to the limited space available on the feeding ship, a special non-acoustic version of the acoustic hood was chosen. The intelligent package control AERtronic takes over the efficient control of the screw blowers and enables safe remote access to the operating and service data of the machines.

Optimised feeding process and better water quality

Digitisation and automation of the pneumatic feeding process offer numerous advantages for people, salmon and the environment. The control system and control of the amount of feed released ensure precise and even distribution in the breeding environment and ensure that all fish have access to the feed - competition is avoided and even growth of the salmon is ensured. It also reduces food wastage in the water. This is not only advantageous from an economic point of view, but also improves the water quality, as the accumulation of food residues can lead to problems due to nutrient build-up and bacterial growth. Pneumatic conveying technology minimises these risks, as only the quantity of feed actually required is dispensed. This means that less uneaten food remains in the water. Another plus - remote operation and remote monitoring reduce the need for constant human intervention, which in turn improves operational efficiency.

Energy savings of more than 30%

With the use of screw blower technology for the pneumatic transport of fish feed, the Chilean aquaculture company is breaking new ground and leading the sector towards a more sustainable future. The AERZEN Delta Hybrid enables considerable savings - both in terms of investment and operating costs. They reduce the carbon footprint, support compliance with ESG requirements (Environmental, Social & Governance) and reduce the size of supplemental equipment such as diesel generators, VFDs or aftercoolers. They also allow a significant increase in production output while maintaining the same level of energy consumption. Thanks to the exceptional energy efficiency of AERZEN's screw blowers at the Chilean salmon farm, two additional production feed lines could be added to the process without increasing the previous demand for electricity. All in all, the fish company has achieved energy savings of more than 30% and a reduction in CO2 emissions of 174 tonnes by switching from conventional positive displacement blowers to AERZEN screw blowers for a complete feeding cycle in seawater (16 months) and a medium-sized feeding vessel with six feeding lines. This

represents a saving of USD 60,000 per cycle. Added to this are fuel (diesel) savings amounting to 64,800 litres of diesel.

On course for the future - for greater efficiency and sustainability

Maximised performance, minimised costs, long-term sustainability: the AERZEN Delta Hybrid has passed its baptism of fire in marine aquaculture with flying colours and will certainly be found frequently in this application in the future. “The pneumatic transport of fish feed with the Delta Hybrid D13S contributes to the continued success of Chile's dynamic salmon farming industry. We are determined to promote this highly productive sector in Chile in a sustainable manner by anticipating and actively contributing to the expected growth,” emphasises César Marin, General Manager of AERZEN Chile.