AERZEN offers the widest product portfolio of customised system solutionsFrom vacuum to compressed air

When it comes to low pressure applications up to 3.5 bar, AERZEN has to be part of the conversation. The company is one of the world's oldest and most important manufacturers of blowers, compressors and turbos and is one of the undisputed market leaders in many fields of application. The high-performance packages prevail for their uncompromising quality, unrivalled durability, attractive life cycle costs and absolute process reliability, ensuring maximum efficiency and productivity.

Tradition meets innovation: compressed air taken further

Low-pressure compressors are an important chapter in AERZEN's success story, but by no means the only one. Oil-free screw compressors have also been part of the portfolio since 1943 - primarily as single-stage packages for process air generation up to 3.5 bar. With the current extension to oil-free and oil-injected compressor series up to 13 bar, AERZEN is positioning itself more broadly in compressed air technology and significantly expanding its expertise. The packages complete the portfolio in the higher pressure range and this opens new fields of application.

High-end solutions for compressed air technology up to 13 bar

“For more than 160 years, our compressor technologies have been considered pioneering in the conveying and compression of gases. Our innovative blowers, compressors and turbos consistently meet customer and market requirements and support them on the journey to higher efficiency and performance,” explains Stephan Brand, Director Marketing at AERZEN, who adds: “our target is to offer our customers the full range of products, solutions and services. Thanks to our new compressed air technologies, we are now also able to cover industrial compressed air applications from 5.5 to 13 bar. This makes us the provider of a full range of products, which opens up new economic perspectives and solutions for our customers, from vacuum to compressed air.”

The AERZEN alternative for economical compressed air

The new packages combine maximum performance and energy efficiency, as well as reliability, and set new standards in compressed air technology. They have been developed to meet the highest demands and are an ideal solution for making processes even more cost-effective, sustainable and efficient. Thanks to their high-power density and reliability, the compact, space-saving screw compressors keep life cycle costs low and ensure significant cost reductions. “Our compressed air packages are state-of-the-art and designed for maximum energy efficiency. They enable energy savings in the double-digit percentage range and thus make an important contribution to greater efficiency and sustainability,” says Stephan Brand. The new compressors are available in oil-free and oil-injected versions and are used wherever working air, instrument air, workshop air, process air or control air for pneumatic control systems is required. This is the case in a wide variety of sectors - be it in food technology, the beverage industry, chemical and process engineering, the textile industry, medical and pharmaceutical technology, electronic and semiconductor production or in the cement and lime industry.

Adaptation to customised process requirements

Every location, every company and every process has its own special features. AERZEN, therefore, offers a wide selection of finely graduated sizes and an enormous variety of customised accessories and spare parts components. The comprehensive range of options and modifications - including coolers, dryers, special motors, special materials, special oils and customised heat recovery systems - allows targeted adaptation to the customer's individual process requirements and ensures the greatest possible flexibility in the design of machines and plants.

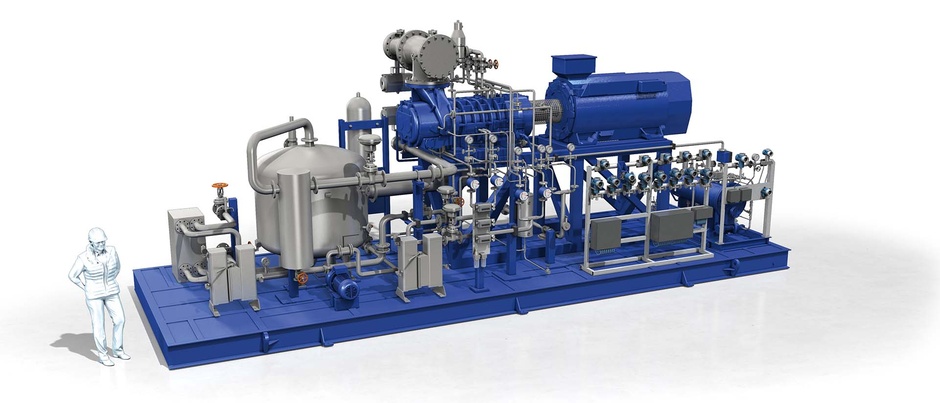

Highly critical processes? AERZEN knows all about these

In addition to the compression of air, the sophisticated conveying of complex gases such as BOG, LNG, hydrogen or biogases is one of AERZEN’s core competences. For these often highly critical processes, AERZEN realises energy-saving, application-optimised high-end solutions including integrated modifications and an extensive range of accessories. The machines are the result of more than 160 years of technological leadership and ensure reliable and safe processes. They are designed for continuous operation and are configured to fulfil all relevant international regulations, building regulations or specifications of the various industries or acceptance companies.

Everything from a single source - from vacuum to compressed air

Whether air or gas, underpressure or positive pressure, oil-free or oil-injected, single-stage or multi-stage, with or without VFD, onshore or offshore, at the bottom of the earth or at the top of a mountain, standard or customised: AERZEN has the widest product portfolio of high-performance compressor solutions and covers almost all requirements. The innovative AERZEN machine technology is the result of the long experience the company has. Our screw compressors, screw blowers, positive displacement blowers, turbo blowers and vacuum blowers are among the most groundbreaking in the market and strengthen the future and competitiveness of our customers.