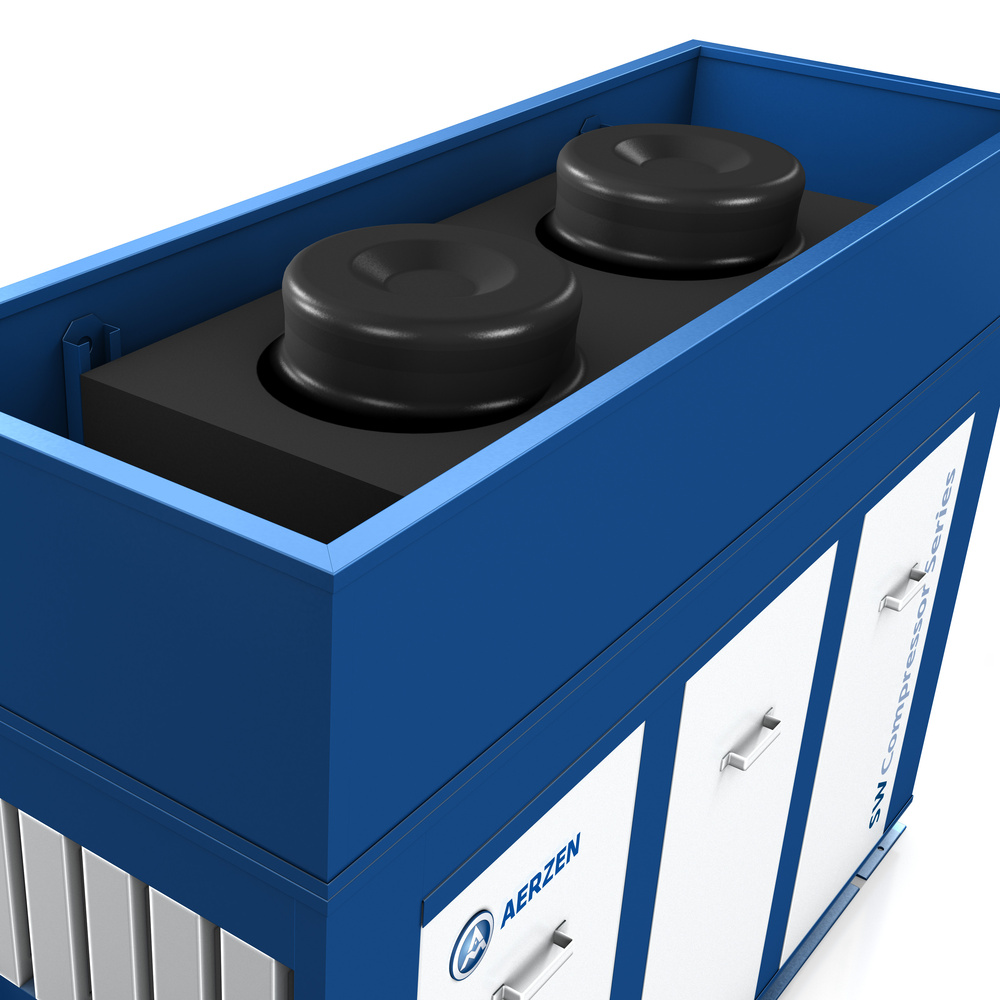

Screw Compressors Water-injected single-stage Screw compressor Series SW

The AERZEN packages of the SW series enable absolutely oil-free compression up to 13 bar with the highest possible energy efficiency and reduced maintenance effort. They are characterised by a unique water purification concept that includes a sealed circuit and integrated treatment: The injected water is "recovered" as condensate by means of a refrigeration dryer after compression. Excess condensate can be disposed of directly without treatment. Furthermore by means of the injection effect the dust particles are “washed out” of the sucked in compressed air. Spores and germs are reduced to a value below the detection limit.

Volume flow:

144

to

1.170

m3/h

Differential pressure (Δp):

4.000

to

13.000

mbar

Medium:

Air,

Neutral Gases

Compression:

Water injected

The advantages of AERZEN Screw Compressors Series SW at a glance:

- Increased energy efficiency and better cooling effect thanks to water injection

- Low operating temperature of maximal 55°C protects the compressor stage and downstream components

- No oil in the compressed air due to constructive separation of conveying chamber and bearing, thus preventing contamination of the compressed air Use of stainless steel rotors for

- reliable operation (prevention of corrosion) and optimum efficiency

- Insensitive compressor design regarding water quality, which saves investment and operating costs and increases system safety

- Easy and reliable water injection by using the pressure differences within the system, a circulation pump is not required

As diverse as your applications

Compressed air is omnipresent in industry and has become indispensable in many applications - be it in chemical/ petrochemical process technology, electronics and semiconductor production, the food and beverage industry, the textile industry, medical technology and many other areas.

US Units

No- Type of technology

- Screw Compressors

- Design

- Positive pressure

- Differential pressure (Δp)

- 4.000 to 13.000 mbar

- Volume flow

- 144 to 1.170 m3/h

- Medium

- Air, Neutral Gases

- Compression

- Water injected

The decisive advantage of the water-injected stages lies in the screw rotors, which are made of high-alloy, corrosion-resistant steel and thus work without deformation even at higher pressures of up to 13 bar. This has significantly reduced the gap dimensions and significantly improved efficiency. The waterinjected compressors of the SW series are directly comparable with the values for oil-injected screw compressors.

AERZEN is also taking an innovative approach to bearings. The highlight: oil-lubricated anti-friction bearings in combination with a special lubricant (ISO VG 46). No use of high-maintenance, grease-lubricated bearings. Your benefit: Permanent lubrication over the entire life cycle of the compressor stage. This eliminates the need to change or top up the oil. An atmospheric gap between the bearings and the compression chamber reliably prevents water from penetrating the oil chamber or oil from entering the water chamber. We offer unrivalled maintenance intervals of at least two years in continuous operation (16,000 operating hours) forthese stages. If service work is required, only the anti-friction bearings and seals ensure to be replaced.

Water-injected single-stage Screw compressor Series SW — Performances & dimensions

| Series | Performance data | Dimensions and weights | ||||

|---|---|---|---|---|---|---|

| Volume flow*, m3/h | Motor power, kw | Width (W), mm | Depth (D), mm | Height (H), mm | Weight, kg | |

| SW 75 | 8 bar | 738 | 75 | 2,800 | 1,500 | 2,200 | 2,000 |

| SW 75 | 10 bar | 672 | 75 | 2,800 | 1,500 | 2,200 | 2,000 |

| SW 75 | 13 bar | 582 | 75 | 2,800 | 1,500 | 2,200 | 2,000 |

| SW 110 | 8 bar | 1,170 | 110 | 3,400 | 1,500 | 2,273 | 3,000 |

| SW 110 | 10 bar | 1,032 | 110 | 3,400 | 1,500 | 2,273 | 3,000 |

| SW 110 | 13 bar | 882 | 110 | 3,400 | 1,500 | 2,273 | 3,000 |

Data available on request without specification

Sound pressure level without blow-off noise, with acoustic enclosure.

* corresponds to the measured delivery volume flow converted to the customer-specific suction conditions p = 1,0 bar, t =20°C, rF = 0%