Turbo Blowers

Compact power in aeration tanks

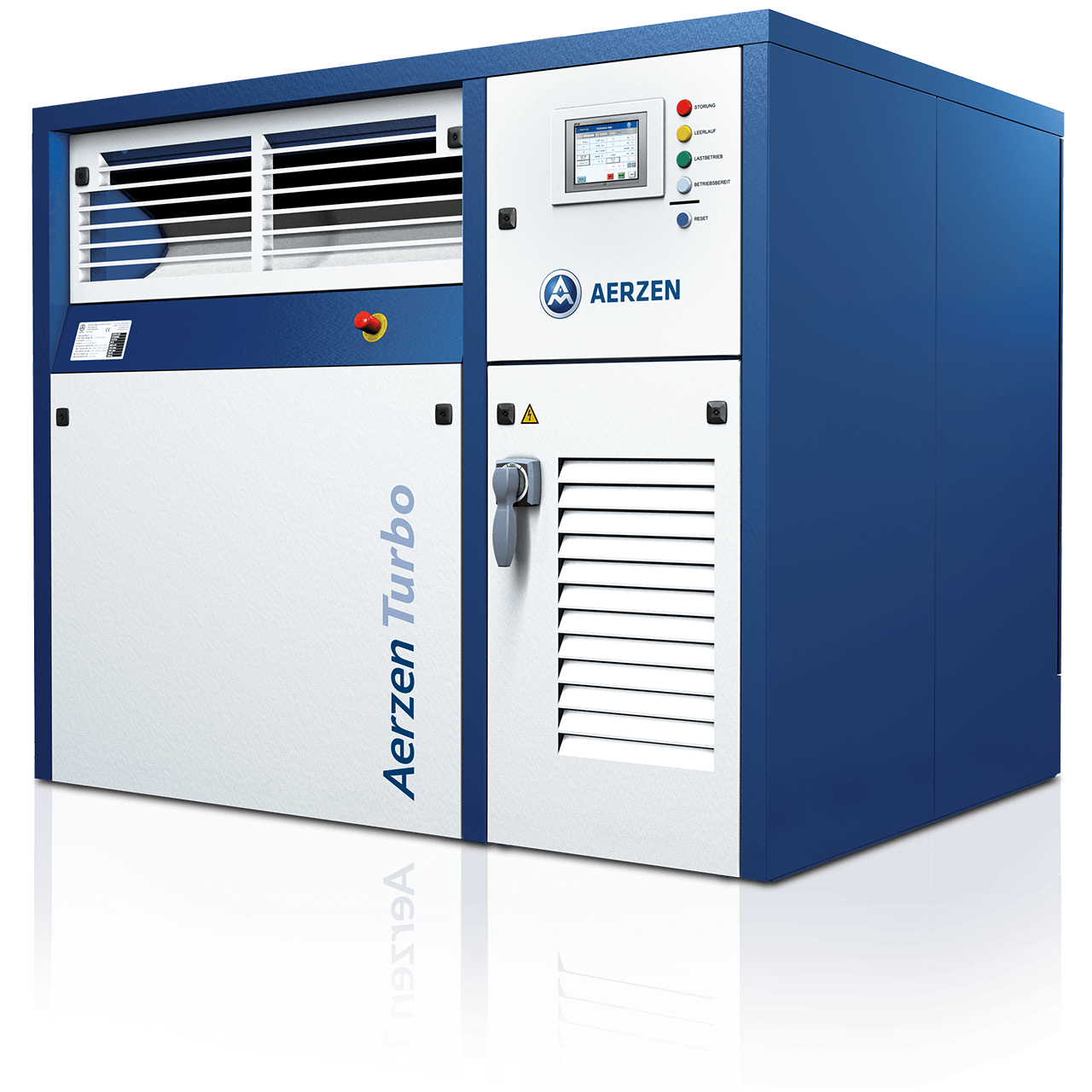

AERZEN is one of the world's leading high-speed turbo blower manufacturers. Since 1911, their top priority has been to build high-speed turbo blowers with reliability, energy efficiency, and low life-cycle costs in mind. While Aerzen turbo blowers have a significantly smaller physical footprint than conventional turbo blowers, they offer reliable performance and high efficiency.

Aeration blowers play an integral role in water and wastewater treatment facilities. The aeration in a typical wastewater treatment plant represents over 50% of the total energy consumption, accounting for up to 75% of the life cycle of a turbo blower.

Capitalizing on the efficiency of a high-speed turbo blower or turbo compressor is an excellent way of improving operational efficiency and dealing with energy concerns in water and wastewater treatment systems. Using high-speed turbo blowers will also help customers reduce their facilities' carbon footprint.

When choosing a high-speed turbo blower to help improve energy savings and lower your carbon footprint, AERZEN turbo blowers are your best bet. Specifically designed to satisfy the demands of biological, industrial, and communal wastewater treatment plants, these high-speed turbo blowers operate on a high-speed, permanent-magnetic motor.

This high-speed motor is significantly more efficient than traditional motors for wastewater treatment applications. A completely oil-free, contact-free and vibration-free air foil bearing helps to drive and adjust the rotating speed of the air-cooled, high-speed motor. The result is exceptionally high efficiency, lower energy consumption, reduced wear, and lower operating costs.

It is essential to provide wastewater treatment aeration tanks with an adequate compressed air supply. Operators can achieve this with high-efficiency turbo blowers from AERZEN. These high-speed turbo blowers feature a relatively simple construction - an aerodynamically designed impeller positioned right on the motor shaft.

The impeller generates volume flow by rotating in a spiral housing. This technology's major drawback is high rotation speeds that range from 20,000 to 70,000 revolutions per minute (rpm). Standard ball bearings or other mechanical bearings aren't practical for such high rotational speeds as they often cause some degree of friction.

AERZEN has developed an incredibly simple solution for the fast-rotating turbo blowers - air bearings. AERZEN turbo blowers feature non-contact air bearings in their drive shaft's radial bearings and the thrust bearing that absorbs axial forces.

When the shaft rotates, it capitalizes on natural imbalance as the high-speed turbo blower starts. This process results in an eccentric circular motion in the air gap between the shaft and bearing, compressing the air or gas in the gap. As the rotating speed increases, the axis positions itself in the center, and air pressure above 30 bar holds it in a contact-free position.

A maintenance-free, two-element coating completes this high-speed turbo blower system. The coating functions as a friction partner between the polished surface when the turbo blower starts and the air cushion forms within milliseconds. The PTFE layer offers excellent sliding properties without the need for a lubricant.

A sheet of steel with an undulating shape complements the air bearing's lubrication layer and absorbs the vibrations, protecting the housing. Unlike AERZEN, other high-speed turbo blower manufacturers utilize magnetic bearing technology on their blower and compressor systems.

While magnetic bearings work as efficiently as air bearings, they have numerous downsides compared to the AERZEN air bearings. Their circularly arranged solenoids require a UPS (uninterrupted power supply) and a more complex system to ensure precise control.

These requirements make magnetic bearing technology expensive and maintenance is needed, significantly increasing life-cycle costs. However, the top priority of customers purchasing a turbo blower is to get high performance and efficient aeration with minimal maintenance and operating costs.

Magnetic bearings' complex design is more prone to problems than the simple design of the air bearing system. Air bearing systems don't require any mechanical, pneumatic, or electrical controls. That's why a high-speed turbo blower or compression unit with this bearing system is more energy efficient, cost-effective, and requires minimal maintenance.

AERZEN uses non-contact air bearing as a standard solution in our AT series high-speed turbo blowers. This bearing technology has numerous benefits over its magnetic and mechanical counterparts. These bearing systems operate on a simple physical principle, improving operational efficiency and promoting high energy savings.

Since the air foil bearing doesn't require external ancillary equipment like electronic control systems, the bearing system has significantly fewer components. This construction makes it less prone to problems than other bearing systems used in high-speed turbo blowers.

The rotor's backup bearings don't necessarily have air bearings. In the event of magnetic field failure, the rotor of a high-speed turbo blower with a magnetic bearing will need the support of mechanical backup bearings. During power failure or other extreme conditions, magnetic bearing requires an extra battery system to supply energy to the bearings for at least 30 seconds, so the rotational speed can drop to a speed that doesn't harm the bearings.

The battery system is not maintenance-free and can malfunction at high and low ambient temperatures or when magnetic fields fail. The magnetic bearings' backup system only functions at extremely low speeds. That means a high-speed turbo blower with magnetic bearing is highly prone to damage at very high speeds, like during recurrent power failures without a sufficiently charged battery system.

Furthermore, it is impossible to repair a faulty magnetic bearing or backup bearings on site. You'll need to send the entire unit to the manufacturer for repairs, resulting in prolonged delays.

On the other hand, AERZEN non-contact air bearings are significantly less prone to damage caused by extreme or fluctuating operation conditions. An AERZEN high-speed turbo blower with an air bearing system can function in extreme situations, such as sudden pressure changes.

The air bearing and its dampening spring components coupled with a high-temperature coating compensate for the sudden changes. Thus, the high-speed turbo blower continues to run safely, efficiently, and reliably.

In addition, AERZEN turbo blowers feature an advanced blower management system with a unique idle function that promotes safe operation and energy efficiency, especially during multiple start-ups or stops. The high-speed turbo blower or compressor will not stop completely with this function. Instead, it rotates at a minimum speed range of 10,000 to 12,000 rpm.

This speed range promotes the creation of sufficient air suspension while ensuring minimal energy consumption (2-5 kW). The entire process helps prevent wear and tear. It's worth noting that you can stop the high-speed turbo blower entirely in the case of prolonged idle operation times.

To uphold optimum efficiency and reliability of a high-speed turbo blower, AERZEN recommends inspecting the bearing system after about 80,000 service hours or ten years. When repairing turbo blowers with air bearing systems, you can replace all related components within a few hours on-site.

If you are looking for a high-speed turbo blower or that is energy efficient, easy to maintain, and has low operational costs, AERZEN has you covered. AERZEN utilizes modern technology in our blower design to ensure excellent energy efficiency, leading to more efficient aeration in wastewater treatment plants and other areas of sewage technologies.

Compared to flow machines from other manufacturers, the AT series turbo blowers are also appropriate for Sequencing Batch Reactor (SBR) Systems. This capability is thanks to their control range and idle operation mode option. The idle mode offers a higher energy efficiency than constantly switching the entire turbo blower unit on and off.

AERZEN also boasts an advanced blower management system that utilizes the Venturi Principle. This system shows you the amount of air your turbo blower delivers at any time. You can enhance the performance of your blower based on the determined values, saving energy and improving your carbon footprint in the long run.

No matter the turbo blower or compressor you choose for your wastewater treatment plant, you are assured of quality. AERZEN turbo blowers and turbo compressors are manufactured with the highest quality and tested to ensure longevity, efficiency, and increased reliability.

Don't hesitate to contact us if you need further information on our high-speed turbo blowers or other products.